Content Menu

● Introduction

● Understanding Customized Dry Food Filling Machines

>> Key Components of a Customized Dry Food Filling Machine

● Types of Customized Dry Food Filling Machines

>> 1. Volumetric Dry Food Dispensers

>> 2. Precision Weighing Fillers

>> 3. Multi-Head Weigher Systems

● Benefits of Customized Dry Food Filling Machines

>> 1. Increased Efficiency

>> 2. Improved Accuracy

>> 3. Versatility

>> 4. Hygiene and Food Safety

>> 5. Reduced Waste

● Applications of Customized Dry Food Filling Machines

>> 1. Grain and Cereal Packaging

>> 2. Nut and Seed Packaging

>> 3. Powdered Food Products

>> 4. Pet Food Packaging

>> 5. Snack Food Packaging

● Technological Advancements in Customized Dry Food Filling Machines

>> 1. IoT Integration

>> 2. Artificial Intelligence and Machine Learning

>> 3. Vision Systems

>> 4. Modular Design

>> 5. Sustainable Solutions

● Choosing the Right Customized Dry Food Filling Machine

● Maintenance and Care of Customized Dry Food Filling Machines

● The Future of Customized Dry Food Filling Machines

● Conclusion

● Frequently Asked Questions

>> 1. What is the typical lifespan of a customized dry food filling machine?

>> 2. Can customized dry food filling machines handle different package sizes without major adjustments?

>> 3. How do customized dry food filling machines ensure consistent fill weights across different products?

>> 4. Are customized dry food filling machines suitable for organic or allergen-free products?

>> 5. How do Industry 4.0 and IoT technologies integrate with customized dry food filling machines?

Introduction

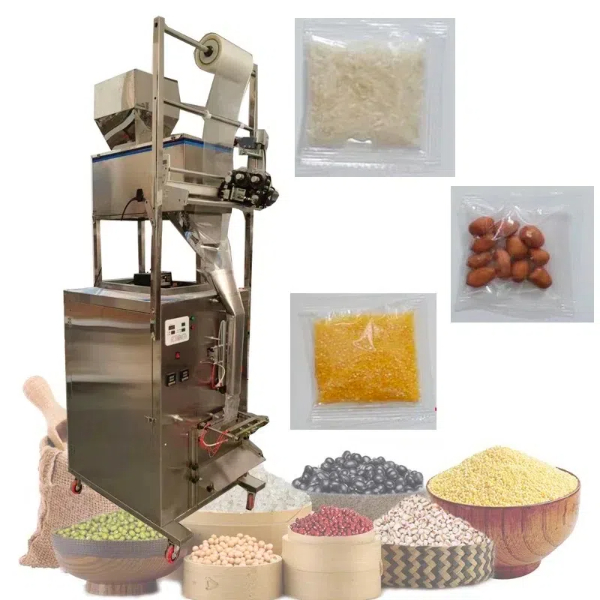

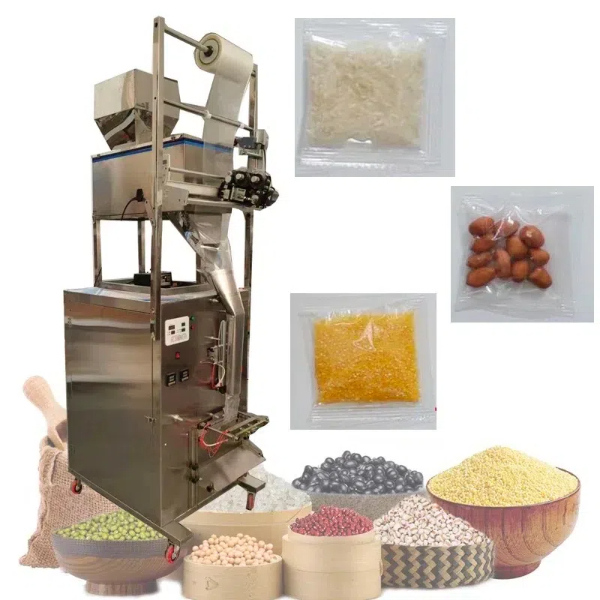

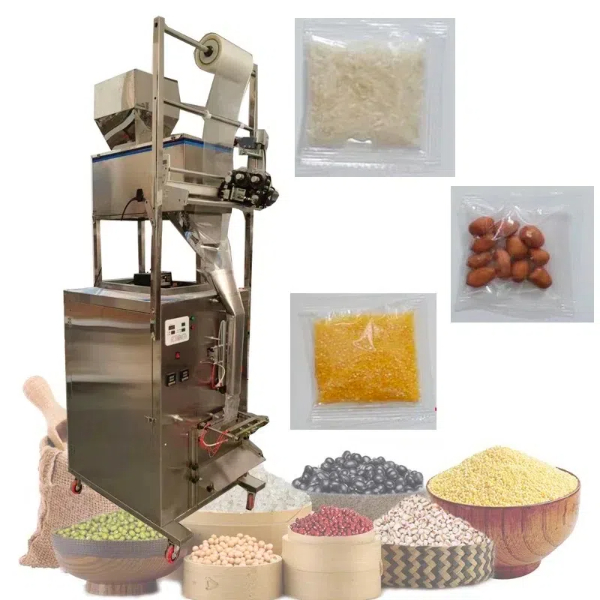

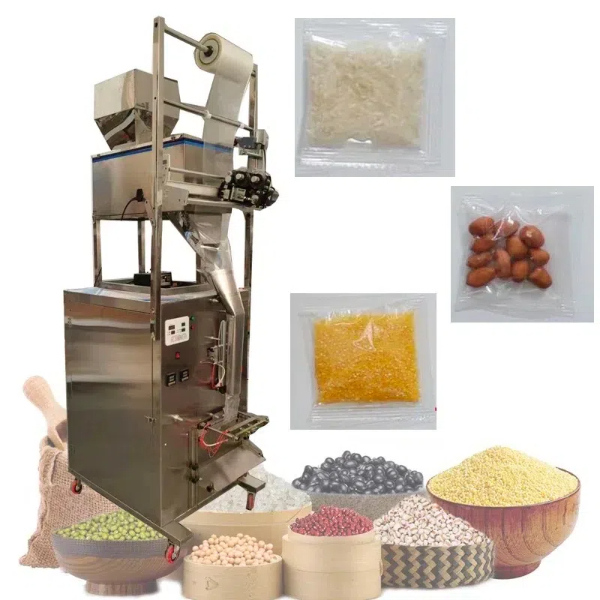

In today's fast-paced food industry, efficiency and precision are paramount. Customized dry food filling machines have emerged as game-changers, offering unparalleled accuracy and speed in packaging various dry food products. These innovative machines are transforming production lines across the globe, from small-scale operations to large industrial facilities. In this comprehensive guide, we'll explore the world of customized dry food filling machines, their benefits, applications, and the latest technological advancements in the field.

Understanding Customized Dry Food Filling Machines

Customized dry food filling machines are specialized equipment designed to accurately measure, dispense, and package dry food products. These machines are tailored to meet specific production requirements, handling a wide range of products such as grains, nuts, seeds, powders, and granules. The customization aspect allows manufacturers to optimize their packaging process for maximum efficiency and product quality.

Key Components of a Customized Dry Food Filling Machine

1. Hopper: The storage container that holds the dry food product before dispensing.

2. Feeding system: Ensures a consistent flow of product into the filling mechanism.

3. Weighing or volumetric system: Measures the precise amount of product for each package.

4. Filling mechanism: Dispenses the measured product into the packaging.

5. Control panel: Allows operators to adjust settings and monitor the filling process.

6. Conveyor system: Moves packages through the filling station.

Types of Customized Dry Food Filling Machines

1. Volumetric Dry Food Dispensers

Volumetric dry food dispensers are ideal for products with consistent density. These machines use a fixed-volume cup or auger to measure and dispense products. They offer high-speed operation and are suitable for a wide range of dry foods, from fine powders to larger granules.

2. Precision Weighing Fillers

For products that require exact weight measurements, precision weighing fillers are the go-to solution. These machines use load cells to weigh the product as it's dispensed, ensuring accuracy to within fractions of a gram. They're particularly useful for high-value products where overfeeding can be costly.

3. Multi-Head Weigher Systems

Multi-head weigher systems are the pinnacle of high-speed, high-accuracy filling. These machines use multiple weighing heads to combine product from different hoppers, achieving the target weight with remarkable precision. They're ideal for mixed products or applications requiring extremely high throughput.

Benefits of Customized Dry Food Filling Machines

1. Increased Efficiency

Customized dry food filling machines significantly boost production efficiency. By automating the filling process, these machines can handle hundreds of packages per minute, far outpacing manual filling methods. This increased speed translates to higher output and reduced labor costs.

2. Improved Accuracy

Precision is crucial in food packaging, both for regulatory compliance and customer satisfaction. Customized filling machines offer unparalleled accuracy, ensuring that each package contains the exact amount of product specified. This precision reduces product giveaway and helps maintain consistent quality across batches.

3. Versatility

One of the key advantages of customized dry food filling machines is their versatility. These machines can be adapted to handle a wide range of products and packaging types. From fine powders to large granules, and from small sachets to large bags, a well-designed filling machine can accommodate various production needs.

4. Hygiene and Food Safety

In the food industry, maintaining strict hygiene standards is non-negotiable. Customized dry food filling machines are typically constructed from food-grade materials, such as stainless steel, which are easy to clean and resistant to bacterial growth. Many models also feature clean-in-place (CIP) systems for thorough sanitization between production runs.

5. Reduced Waste

By precisely measuring and dispensing products, customized filling machines minimize overfilling and product spillage. This reduction in waste not only saves on raw material costs but also contributes to more sustainable production practices.

Applications of Customized Dry Food Filling Machines

Customized dry food filling machines find applications across a wide spectrum of the food industry. Here are some common use cases:

1. Grain and Cereal Packaging

From rice and quinoa to breakfast cereals, grain packaging requires high-speed, accurate filling. Customized machines can handle delicate flakes without breakage while ensuring consistent package weights.

2. Nut and Seed Packaging

Nuts and seeds present unique challenges due to their irregular shapes and tendency to bridge or jam. Specialized filling machines use vibration and custom-designed hoppers to ensure smooth product flow and accurate dispensing.

3. Powdered Food Products

Fine powders like flour, sugar, and powdered milk require specialized filling equipment to prevent dusting and ensure accurate measurements. Customized machines often incorporate dust extraction systems and specialized augers for these applications.

4. Pet Food Packaging

The pet food industry relies heavily on efficient packaging solutions. Customized dry food filling machines can handle various kibble sizes and shapes, ensuring consistent portion sizes for different pet food brands.

5. Snack Food Packaging

From chips to trail mix, snack foods require gentle handling and precise portioning. Customized filling machines can be equipped with special features like cushioned drop chutes to prevent product breakage during the filling process.

Technological Advancements in Customized Dry Food Filling Machines

The field of customized dry food filling machines is constantly evolving, with new technologies enhancing performance and functionality. Here are some of the latest advancements:

1. IoT Integration

Internet of Things (IoT) technology is revolutionizing the food packaging industry. Modern filling machines can be connected to central control systems, allowing real-time monitoring of production metrics, predictive maintenance, and remote troubleshooting.

2. Artificial Intelligence and Machine Learning

AI and machine learning algorithms are being incorporated into filling machines to optimize performance. These systems can analyze production data to suggest improvements in machine settings, predict maintenance needs, and even adjust filling parameters in real-time based on product variations.

3. Vision Systems

Advanced vision systems are being integrated into filling machines to enhance quality control. These systems can detect foreign objects, verify fill levels, and ensure proper package sealing, all at high speeds.

4. Modular Design

The trend towards modular machine design allows for greater flexibility and easier upgrades. Manufacturers can quickly adapt their filling lines to new products or packaging formats by swapping out modules rather than replacing entire machines.

5. Sustainable Solutions

As sustainability becomes increasingly important, filling machine manufacturers are developing eco-friendly solutions. This includes machines designed to work with biodegradable packaging materials and systems that minimize energy consumption and product waste.

Choosing the Right Customized Dry Food Filling Machine

Selecting the appropriate filling machine for your operation is crucial for maximizing efficiency and product quality. Here are some factors to consider:

1. Product characteristics (density, flowability, particle size)

2. Required production speed

3. Accuracy requirements

4. Packaging type and size range

5. Cleaning and sanitation needs

6. Available floor space

7. Budget constraints

8. Future production plans and scalability

Working closely with experienced equipment suppliers can help ensure you select a machine that meets your current needs and can adapt to future requirements.

Maintenance and Care of Customized Dry Food Filling Machines

Proper maintenance is essential for ensuring the longevity and optimal performance of your customized dry food filling machine. Regular cleaning, lubrication, and inspection of key components can prevent unexpected downtime and extend the machine's lifespan. Many modern machines come with built-in maintenance reminders and self-diagnostic systems to simplify the maintenance process.

The Future of Customized Dry Food Filling Machines

As technology continues to advance, we can expect to see even more innovative features in customized dry food filling machines. Some potential developments include:

1. Enhanced automation with collaborative robots for tasks like package loading and palletizing

2. Greater integration with other packaging line components for seamless end-to-end solutions

3. Advanced materials and designs for improved hygiene and easier cleaning

4. Increased use of sustainable and recyclable materials in machine construction

5. Further improvements in energy efficiency and reduced environmental impact

Conclusion

Customized dry food filling machines have become indispensable tools in the modern food packaging industry. By offering unparalleled speed, accuracy, and versatility, these machines are helping food manufacturers meet the growing demands of consumers and regulatory bodies alike. As technology continues to evolve, we can expect these machines to become even more sophisticated, further revolutionizing the way we package and distribute dry food products.

Whether you're a small artisanal food producer or a large-scale industrial manufacturer, investing in a customized dry food filling machine can significantly enhance your production capabilities. By carefully considering your specific needs and staying informed about the latest technological advancements, you can choose a filling solution that will serve your business well into the future.

Frequently Asked Questions

1. What is the typical lifespan of a customized dry food filling machine?

Answer: The lifespan of a customized dry food filling machine can vary depending on factors such as usage, maintenance, and build quality. However, with proper care and regular maintenance, many high-quality machines can last 15-20 years or more. It's important to follow the manufacturer's recommended maintenance schedule and address any issues promptly to maximize the machine's lifespan.

2. Can customized dry food filling machines handle different package sizes without major adjustments?

Answer: Many modern customized dry food filling machines are designed with flexibility in mind. They often feature quick-change parts and adjustable settings that allow for relatively easy transitions between different package sizes. Some advanced models even offer automatic adjustment capabilities, minimizing downtime during product changeovers. However, the extent of adjustability can vary between machines, so it's important to discuss your specific needs with the manufacturer when selecting a machine.

3. How do customized dry food filling machines ensure consistent fill weights across different products?

Answer: Customized dry food filling machines use various technologies to ensure consistent fill weights. For volumetric fillers, this might involve precisely calibrated augers or cups. Weight-based systems use load cells to measure the exact weight of the product being dispensed. Many machines also incorporate feedback loops that continuously monitor and adjust the filling process to maintain accuracy. Additionally, some advanced systems use product databases and AI algorithms to automatically adjust settings based on the specific characteristics of each product.

4. Are customized dry food filling machines suitable for organic or allergen-free products?

Answer: Yes, customized dry food filling machines can be designed to meet the stringent requirements of organic and allergen-free production. These machines often feature food-grade stainless steel construction, easy-to-clean surfaces, and minimal product retention areas to prevent cross-contamination. Some models also offer clean-in-place (CIP) systems for thorough sanitization between production runs. When ordering a machine for allergen-free or organic products, be sure to specify these requirements to ensure the machine meets all necessary certifications and standards.

5. How do Industry 4.0 and IoT technologies integrate with customized dry food filling machines?

Answer: Industry 4.0 and IoT technologies are increasingly being integrated into customized dry food filling machines, offering numerous benefits:

- Real-time monitoring: Sensors throughout the machine can provide continuous data on performance metrics, allowing for immediate adjustments and optimization.

- Predictive maintenance: By analyzing operational data, these systems can predict when maintenance will be needed, reducing unexpected downtime.

- Remote diagnostics: Technicians can access machine data remotely, often resolving issues without the need for on-site visits.

- Production tracking: Integrated systems can provide detailed production data, aiding in quality control and regulatory compliance.

- Supply chain integration: IoT-enabled machines can communicate with inventory systems, automatically triggering orders for raw materials or packaging supplies as needed.

These technologies not only improve efficiency and reduce downtime but also provide valuable insights for continuous improvement of the production process.