Content Menu

● Introduction to Dehydrator Machines

>> Basic Components of a Dehydrator

● Working Principle of Dehydrator Machines

● Types of Dehydrators

>> 1. Conventional Dehydrators

>> 2. Heat Pump Dehydrators

>> 3. Solar Dehydrators

● Applications of Dehydrators

● OEM Services for Dehydrator Machines

>> Customization Options

● Benefits of Using Dehydrators

● Safety Considerations

● Conclusion

● FAQs

>> 1. What is the primary function of a dehydrator?

>> 2. How does a heat pump dehydrator work?

>> 3. What are the benefits of using a dehydrator?

>> 4. Can dehydrators be customized for specific applications?

>> 5. What types of food can be dehydrated?

● Citations:

Food dehydrators are essential tools in the food industry, used for preserving fruits, vegetables, meats, and other food products by removing moisture. This process not only extends the shelf life of food but also retains its nutritional value and texture. In this article, we will delve into the working principle of dehydrator machines, their types, and their applications, along with providing insights into how they can be customized for OEM services.

Introduction to Dehydrator Machines

A dehydrator machine is essentially a device that uses controlled temperature, airflow, and humidity to evaporate moisture from food. This process is crucial for preserving food as it inhibits the growth of bacteria and other microorganisms that thrive in moist environments.

Basic Components of a Dehydrator

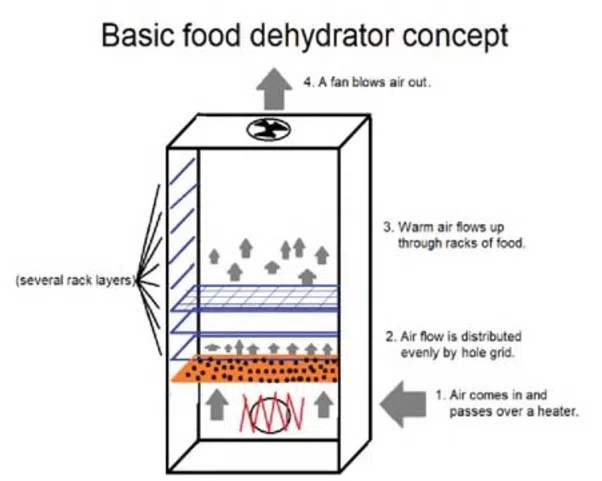

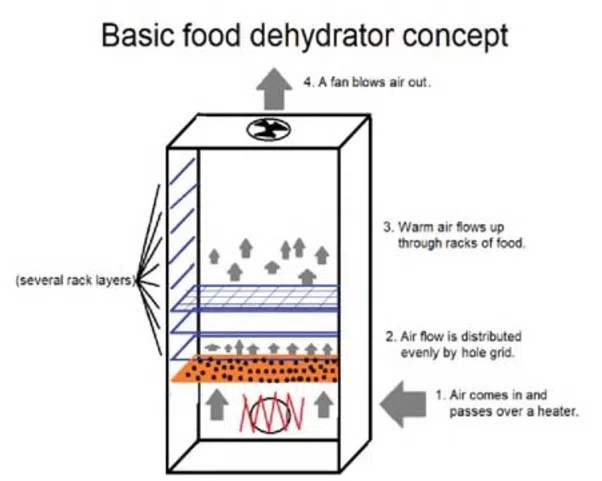

1. Heating Element: This is typically an electric heater or gas heat source that generates hot air.

2. Fan or Blower: Circulates the hot air evenly over the food to accelerate moisture evaporation.

3. Trays or Racks: These are usually perforated to allow air to pass through and come into contact with the food.

4. Temperature Control: Allows for adjusting the temperature to suit different types of food.

5. Humidity Control: Some advanced models can monitor and adjust humidity levels to ensure optimal drying conditions.

Working Principle of Dehydrator Machines

The working principle of a dehydrator involves circulating hot air over the food to remove moisture. Here's a step-by-step explanation:

1. Circulation of Hot Air: The heating element generates hot air, which is circulated by a fan or blower.

2. Temperature Control: The temperature is adjusted according to the type of food being dehydrated.

3. Humidity Control: Advanced models monitor and adjust humidity to prevent over-drying or under-drying.

4. Ventilation: Perforated trays allow air to pass through, ensuring even drying.

Types of Dehydrators

1. Conventional Dehydrators

These are the most common type, using electric heaters and fans to circulate hot air. They are suitable for home use and small-scale commercial applications.

2. Heat Pump Dehydrators

Heat pump dehydrators use a refrigeration cycle to heat and dry food. They are energy-efficient and suitable for large-scale industrial applications.

3. Solar Dehydrators

Solar dehydrators use sunlight as the heat source and are environmentally friendly. They are ideal for areas with abundant sunlight and are often used in rural or off-grid settings.

Applications of Dehydrators

Dehydrators are used in various industries:

- Food Preservation: For fruits, vegetables, meats, and herbs.

- Industrial Drying: For materials like wood, leather, and textiles.

- Pharmaceuticals: For drying medicinal herbs and materials.

OEM Services for Dehydrator Machines

As a manufacturer, we provide OEM services to customize dehydrators according to the specifications of foreign brands, wholesalers, and manufacturers. This includes designing the machine's size, temperature range, and features to meet specific requirements.

Customization Options

1. Temperature Range: Adjusting the temperature range to suit different types of food.

2. Tray Size and Material: Customizing tray sizes and materials for specific food products.

3. Humidity Control: Integrating advanced humidity control systems for precise drying conditions.

4. Energy Efficiency: Optimizing energy consumption for cost-effective operation.

Benefits of Using Dehydrators

1. Food Preservation: Dehydrators help extend the shelf life of food by removing moisture, which inhibits bacterial growth.

2. Nutritional Retention: The drying process helps retain the nutritional value of food.

3. Space Efficiency: Dehydrated food takes up less storage space, making it ideal for long-term storage.

4. Energy Efficiency: Heat pump dehydrators offer significant energy savings compared to conventional models.

Safety Considerations

When using a dehydrator, it's important to follow safety guidelines:

1. Temperature Monitoring: Ensure the temperature is set correctly to avoid over-drying or under-drying.

2. Cleaning: Regularly clean the dehydrator to prevent bacterial growth.

3. Ventilation: Ensure good ventilation in the area where the dehydrator is used.

Conclusion

In conclusion, dehydrator machines play a vital role in preserving food by removing moisture, thereby extending its shelf life. Understanding how a dehydrator works is essential for optimizing its use in both domestic and industrial settings. Whether you are looking for conventional or heat pump dehydrators, customization options are available to meet specific needs.

FAQs

1. What is the primary function of a dehydrator?

- The primary function of a dehydrator is to remove moisture from food, extending its shelf life and preserving its nutritional value.

2. How does a heat pump dehydrator work?

- A heat pump dehydrator uses a refrigeration cycle to heat and dry food. It involves components like an evaporator, compressor, and condenser to circulate hot air.

3. What are the benefits of using a dehydrator?

- The benefits include preserving food, reducing storage space, and retaining nutritional value. Dehydrators also offer energy efficiency, especially with heat pump models.

4. Can dehydrators be customized for specific applications?

- Yes, dehydrators can be customized for specific applications, including adjusting temperature ranges, size, and features to meet the needs of different industries or brands.

5. What types of food can be dehydrated?

- A wide variety of foods can be dehydrated, including fruits, vegetables, meats, herbs, and even seafood. The temperature and drying time may vary depending on the food type.

Citations:

[1] https://septree.com/pages/what-is-the-working-principle-of-food-dryer

[2] https://hpdryer.com/how-does-a-food-dehydrator-work/

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.bxdryer.com/news/industry-news/how-food-dehydrator-works-news.html

[5] https://www.mitchellcooper.co.uk/what-is-a-dehydrator-commercial-buying-guide

[6] https://patents.google.com/patent/CN114753102B/zh

[7] https://pocketchangegourmet.com/how-does-a-dehydrator-work/

[8] https://etsolutions.in/how-does-a-food-dehydrator-work-explore-the-benefits-of-food-dehydrators/

[9] https://en.wikipedia.org/wiki/Food_dehydrator