Content Menu

● Introduction

● Key Features and Benefits

● Preparation

>> Cleaning the Dehydrator

>> Inspecting the Unit

● Food Preparation

>> Selecting Fresh Produce

>> Washing Thoroughly

>> Slicing Evenly

>> Pre-treatment (Optional)

● Optimizing Dehydrator Performance

>> Spacing Matters

>> Humidity Control

>> Strategic Timing

>> Full Loads

>> Proper Maintenance

>> Well-Insulated Area

>> Batch Processing

>> Adjust Temperature Settings

>> Regular Cleaning

>> Prevent Cross-Contamination

>> Monitor for Consistent Airflow

>> Check Seals and Gaskets

>> Rotate Trays During Drying

● Advanced Settings

● Energy Efficiency Tips

>> Batch Processing

>> Full Loads

>> Off-Peak Hours

>> Temperature Adjustment

● Storage Tips

>> Proper Packaging

>> Cool, Dark Place

>> Monitoring Stored Foods

● Best Practices for OEM Manufacturers

>> Quality Control

>> User Manuals

>> Training Programs

>> Customer Support

● Maintenance and Hygiene

>> Regular Cleaning

● Additional Tips for Energy-Efficient Dehydrator Use

● Conclusion

● FAQ

>> 1. How often should I clean my cabinet type dehydrator?

>> 2. What is the ideal thickness for slicing food before dehydration?

>> 3. How can I prevent browning of fruits during dehydration?

>> 4. What are the best practices for energy-efficient dehydration?

>> 5. How do I ensure even drying in my cabinet type dehydrator?

● Citations:

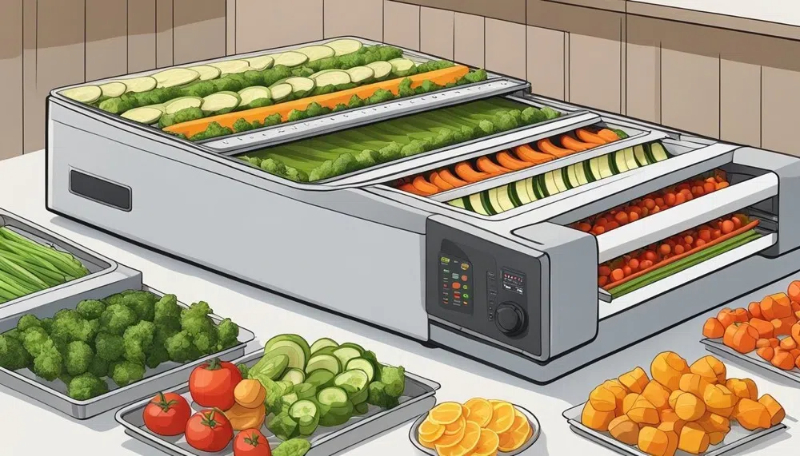

Introduction

As a Chinese food dehydrator manufacturing factory providing OEM services to international food dehydrator brands, wholesalers, and manufacturers, understanding the nuances of efficient dehydrator use is critical. Cabinet type dehydrators are specialized, self-contained units designed to remove moisture from food products, enhancing shelf life and preserving natural qualities. These dehydrators offer a controlled environment, ensuring uniform drying, superior product quality, and minimal waste. This guide provides comprehensive insights into optimizing the use of cabinet type dehydrators.

Key Features and Benefits

Cabinet type dehydrators integrate a heat pump dryer with a precisely controlled chamber to optimize performance and maximize energy efficiency. Their key features and benefits include:

- High Efficiency: Ensures consistent dehydration while minimizing energy waste.

- Versatility: Can dry a wide range of foods, including fruits, vegetables, meats, herbs, and spices.

- Precise Control: Offers precise temperature and airflow control, ensuring even dehydration and preserving the integrity of textures and flavors.

- Hygienic Environment: The enclosed design minimizes contamination from dust, insects, and other environmental factors, providing a hygienic environment for food processing.

- Extended Shelf Life: Effectively removes moisture, significantly increasing the shelf life of food products.

- Nutrient Preservation: Preserves the natural flavors, colors, and nutrients in food.

- Waste Reduction: Helps convert seasonal harvests into all-season products, minimizing food waste.

- Energy Efficiency: Optimizes energy use by integrating a heat pump dryer and minimizing heat loss through insulation.

- Consistent Results: Maintains uniform temperature and air circulation throughout the cabinet, providing consistent results.

- Reduced Labor: Reduces labor costs and enhances productivity.

- User-Friendly Operation: Equipped with user-friendly controls and digital displays, making it easy to monitor and adjust settings for optimal drying results.

- Sanitary Drying: The enclosed cabinet design ensures sanitary drying conditions, protecting food from external contaminants and ensuring food safety.

Preparation

Cleaning the Dehydrator

Before the first use and after each subsequent use, thoroughly clean the trays and the inside of the cabinet. Use a food-safe detergent and warm water to clean all surfaces, then rinse thoroughly and allow to dry. This practice prevents the transfer of flavors and odors between batches and ensures a hygienic drying environment. Make sure to remove any leftover food particles or residue to prevent bacterial growth.

Inspecting the Unit

Ensure all components are in good working condition. Check the power cord, temperature controls, and fan for any signs of damage or wear. Verify that the door seals properly to maintain a consistent internal environment. A well-maintained unit operates more efficiently and safely, prolonging its lifespan.

Food Preparation

Selecting Fresh Produce

Choose high-quality, fresh, and ripe fruits, vegetables, or other food items. Avoid using produce that is bruised or damaged. Ripe produce has higher sugar content and better flavor, which intensifies during dehydration. Avoid overripe produce, as it can become mushy during the drying process.

Washing Thoroughly

Wash the food thoroughly to remove any dirt, debris, or contaminants. Use a vegetable brush to scrub away any stubborn dirt. Pay close attention to leafy greens and root vegetables, which often harbor more dirt. Proper washing is crucial for food safety and helps to prevent the growth of harmful bacteria.

Slicing Evenly

Cut the food into even slices to ensure uniform drying. Aim for a thickness of about 1/4 inch (6mm). Use a mandoline or food slicer for consistent thickness. Uneven slices will dry at different rates, leading to some pieces being over-dried while others remain moist. Consistent thickness guarantees a consistent final product.

Pre-treatment (Optional)

Some fruits and vegetables benefit from pre-treatment to prevent browning or enhance flavor. Options include blanching, dipping in lemon juice, or using ascorbic acid. Blanching involves briefly immersing vegetables in boiling water to deactivate enzymes that cause discoloration and nutrient loss. Lemon juice and ascorbic acid act as antioxidants to prevent browning. For fruits like apples, bananas, and peaches, dipping them in a solution of lemon juice or ascorbic acid can preserve their color and prevent oxidation.

Optimizing Dehydrator Performance

Spacing Matters

Ensure sufficient spacing between trays to allow for optimal airflow. Insufficient spacing can lead to uneven drying and increased drying times. Airflow is crucial for moisture removal; without it, the food will take longer to dry and may develop mold or bacteria.

Humidity Control

Humidity levels can significantly impact drying times. In humid environments, it may be necessary to increase the drying time or temperature to achieve the desired dryness. Using a dehumidifier in the room where the dehydrator is located can help to reduce humidity levels.

Strategic Timing

Operate during off-peak hours to save on energy costs. Many utility companies offer lower electricity rates during off-peak hours, typically at night or early morning. Check with your local utility provider for specific rates and schedules.

Full Loads

Operate with full loads to maximize efficiency. A fully loaded dehydrator utilizes the available space and energy more efficiently than a partially loaded one. However, avoid overcrowding, as this can impede airflow and lead to uneven drying. Distribute food evenly on the trays to ensure uniform drying.

Proper Maintenance

Regularly inspect and maintain the dehydrator to ensure it is running efficiently. Clean the fan and heating element regularly to remove any dust or debris that may be affecting performance. Check the door seals and gaskets to ensure they are in good condition. Damaged seals can lead to heat loss and uneven drying.

Well-Insulated Area

Place the dehydrator in a well-insulated area to reduce energy consumption. Avoid placing the dehydrator in drafty areas or near windows, as this can increase energy consumption. A stable environment helps the dehydrator maintain a consistent temperature and dry the food more efficiently.

Batch Processing

Consider batch processing to improve energy efficiency. Prepare multiple batches of food at once to minimize the number of times the dehydrator needs to be heated up. This is particularly effective when dealing with seasonal produce.

Adjust Temperature Settings

Use precise temperature settings to prevent scorching or under-drying of food products. Follow recommended temperature guidelines for different types of food to achieve the best results. Use a thermometer to verify the internal temperature of the dehydrator.

Regular Cleaning

Clean the dehydrator after each use to prevent the buildup of food residue and odors. Use a mild detergent and warm water to clean the trays and interior surfaces. Avoid using abrasive cleaners, as they can damage the dehydrator.

Prevent Cross-Contamination

Avoid dehydrating raw meats and produce simultaneously to prevent cross-contamination. Use separate trays and thoroughly clean the dehydrator after dehydrating meats. This is crucial for food safety and prevents the spread of harmful bacteria.

Monitor for Consistent Airflow

Ensure that the fan is functioning correctly and that there are no obstructions blocking airflow. Proper airflow is essential for even drying. Check the fan regularly to ensure it is clean and free of debris.

Check Seals and Gaskets

Inspect the door seals and gaskets regularly to ensure they are in good condition. Damaged seals can lead to heat loss and uneven drying. Replace any damaged seals or gaskets to maintain the dehydrator's efficiency.

Rotate Trays During Drying

Dehydrators have warmer and cooler spots, and areas closer to the fan. Rotate the trays from front to back and top to bottom to ensure even drying, shorter dehydrating times, and less energy use. Tray rotation ensures that all food items receive the same amount of heat and airflow, resulting in a more consistent final product.

Advanced Settings

Modern cabinet dehydrators often come with advanced settings such as multi-stage drying programs, which allow you to set different temperatures and airflow rates for different stages of the drying process. This can be particularly useful for foods that require a gradual drying process. For example, you can start with a higher temperature to quickly remove surface moisture and then lower the temperature to prevent scorching as the food becomes drier. Look for features like automatic shut-off, digital displays, and programmable settings to enhance your dehydration process.

Energy Efficiency Tips

Batch Processing

Process multiple batches to minimize dehydrator heating and save electricity and time. It takes energy to get the dehydrator up to temperature, so running consecutive batches maximizes this initial energy input. Plan your dehydration schedule to take advantage of batch processing, and consider preparing multiple types of food at once to optimize energy usage. Batch processing not only saves energy but also reduces the overall time spent on dehydration.

Full Loads

Operate the dehydrator with full loads whenever possible to maximize energy efficiency. A fully loaded dehydrator utilizes the available space and energy more efficiently than a partially loaded one. However, avoid overcrowding, as this can impede airflow and lead to uneven drying. Arrange the food items in a single layer on the trays, ensuring that there is enough space between them for proper air circulation.

Off-Peak Hours

Use the dehydrator during off-peak hours to take advantage of lower electricity rates. Many utility companies offer lower electricity rates during off-peak hours, typically at night. Check with your local utility provider for specific rates and schedules. Shifting your dehydration activities to off-peak hours can significantly reduce your energy costs.

Temperature Adjustment

Tweak the heat as you go; start higher and then lower it for the end. This can help speed up the initial drying process and then reduce the risk of scorching as the food becomes drier. This technique is especially useful for thicker cuts of meat and fruit. Adjusting the temperature according to the stage of dehydration ensures that the food dries evenly without burning or becoming overly hard.

Storage Tips

Proper Packaging

Proper packaging is essential for maintaining the quality and extending the shelf life of dehydrated foods. Store dried foods in airtight containers or resealable plastic bags to prevent moisture reabsorption. Vacuum-sealed bags are particularly effective for long-term storage. Label the containers with the date of dehydration and the contents.

Cool, Dark Place

Store dried foods in a cool, dark, and dry place. Avoid storing them in direct sunlight or near sources of heat, as this can degrade their quality and shorten their shelf life. A pantry or a cool basement is ideal for storing dehydrated foods.

Monitoring Stored Foods

Regularly check stored foods for signs of moisture or spoilage. Discard any foods that show signs of mold or discoloration. Properly stored dehydrated foods can last for several months to a year or more, depending on the type of food and storage conditions.

Best Practices for OEM Manufacturers

Quality Control

Implement rigorous quality control measures to ensure that your cabinet type dehydrators meet the highest standards of performance and safety. Conduct thorough testing of all components and finished products to identify and address any potential issues.

User Manuals

Provide comprehensive user manuals with clear and concise instructions on how to use and maintain the dehydrator. Include information on food preparation, temperature settings, drying times, and troubleshooting. A well-written user manual enhances customer satisfaction and reduces the likelihood of misuse or damage.

Training Programs

Offer training programs for your customers and their employees on the proper use and maintenance of cabinet type dehydrators. This can include online tutorials, workshops, and on-site training sessions. Properly trained users are more likely to operate the dehydrator efficiently and safely.

Customer Support

Provide excellent customer support to address any questions or concerns that your customers may have. This can include phone support, email support, and online chat. Prompt and helpful customer support enhances customer loyalty and strengthens your brand reputation.

Maintenance and Hygiene

Regular Cleaning

You should clean your cabinet dehydrator after each use to prevent buildup and maintain hygiene. Regularly inspect the dehydrator for any signs of wear and tear, and schedule professional servicing at regular intervals to ensure optimal performance. This includes checking the heating element, fan motor, and control panel. Regular servicing helps to identify and address any potential issues before they become major problems.

Additional Tips for Energy-Efficient Dehydrator Use

- Fill the unit: Maximize each load to avoid wasting energy.

- Mix and match Loads: Combine foods with similar drying times.

- Use the right tray accessories: Utilize accessories to improve airflow and efficiency.

- Choose a good drying space: Place the dehydrator in a well-ventilated area.

- Choose to dehydrate on good drying days: When possible, dehydrate on days with low humidity.

- Don't overload the appliance: Overloading can lead to uneven drying and increased energy use.

- Package Soon After Cooling: Package dried foods promptly after cooling to maintain quality.

Conclusion

Efficient use of cabinet type dehydrators involves careful preparation, optimized operation, consistent storage, and stringent maintenance. By following these guidelines, OEM service providers can ensure high-quality output, energy efficiency, and customer satisfaction. This approach not only enhances the product's functionality but also supports sustainable and cost-effective practices in food processing.

FAQ

1. How often should I clean my cabinet type dehydrator?

Clean your cabinet type dehydrator after each use to prevent buildup and maintain hygiene. Regular cleaning helps to avoid cross-contamination, ensures optimal performance, and extends the lifespan of the unit. Use a soft cloth or sponge to clean the interior surfaces, and avoid using abrasive cleaners that could damage the dehydrator.

2. What is the ideal thickness for slicing food before dehydration?

Aim for a thickness of about 1/4 inch (6mm) when slicing food for dehydration. Consistent thickness ensures uniform drying and helps to achieve the best results. Use a mandoline or food slicer to ensure consistent thickness across all slices.

3. How can I prevent browning of fruits during dehydration?

Pre-treat fruits by blanching, dipping them in lemon juice, or using ascorbic acid to prevent browning. These methods help to deactivate enzymes and act as antioxidants, preserving the color and quality of the fruit. Consider using a combination of methods for optimal results.

4. What are the best practices for energy-efficient dehydration?

To improve energy efficiency, consider batch processing, operating with full loads, using strategic timing during off-peak hours, adjusting temperature settings, and ensuring proper maintenance. Additionally, placing the dehydrator in a well-insulated area can help reduce energy consumption. Regularly check the dehydrator for any issues that could be affecting its energy efficiency.

5. How do I ensure even drying in my cabinet type dehydrator?

Ensure sufficient spacing between trays to allow for optimal airflow. Rotate trays during drying to ensure even drying, shorter dehydrating times, and less energy use. Also, monitor for consistent airflow and check seals and gaskets regularly to prevent heat loss and uneven drying. Proper airflow is essential for achieving uniform drying.

Citations:

[1] https://www.dryeratech.com/what-you-need-to-know-about-operating-a-cabinet-type-dehydrator.html

[2] https://gardening.org/dehydrator-tips/

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/best-practices-for-using-your-cabinet-type-dehydrator-effectively.html

[5] https://www.osbheatpump.com/news/how-to-use-a-food-dehydrator-10-useful-tips-for-beginners-and-advanced-users/

[6] https://www.electrolux-ui.com/DocumentDownLoad.aspx?DocURL=2011%5C136%5C918250umEN.pdf

[7] https://excaliburdehydrator.com/pages/dehydrating-tips

[8] https://homesteadingfamily.com/preservation-101-intro-to-dehydrating-food/