Content Menu

● Introduction to Heat Pump Dryers

● How Heat Pump Dryers Work

>> The Basic Principle

>> The Drying Process

● Advantages of Heat Pump Dryers for Food Processing

>> Energy Efficiency

>> Preservation of Nutritional Value

>> Versatility

>> Reduced Environmental Impact

● Comparison with Traditional Drying Methods

>> Conventional Dryers

>> Heat Pump Dryers

● Applications of Heat Pump Dryers in Food Processing

>> Fruit and Vegetable Drying

>> Meat Drying

>> Snack Food Production

>> Herbal Drying

● Maintenance and Operation of Heat Pump Dryers

>> Regular Maintenance

>> Operating Tips

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer for food processing?

>> 2. Can heat pump dryers be used for all types of food?

>> 3. How does a heat pump dryer differ from a conventional dryer?

>> 4. What maintenance is required for heat pump dryers?

>> 5. What types of food products are commonly dried using heat pump dryers?

Introduction to Heat Pump Dryers

Heat pump dryers are an innovative solution for drying food products efficiently and effectively. Unlike traditional dryers that rely on direct heat, heat pump dryers utilize a closed-loop system that recycles air, making them more energy-efficient and environmentally friendly. This technology is particularly beneficial for food processing, where maintaining the quality and nutritional value of the product is crucial.

In this article, we will explore the workings of heat pump dryers, their advantages in food drying applications, and how they differ from conventional drying methods. We will also provide a detailed diagram of a heat pump dryer to illustrate its components and operation.

How Heat Pump Dryers Work

The Basic Principle

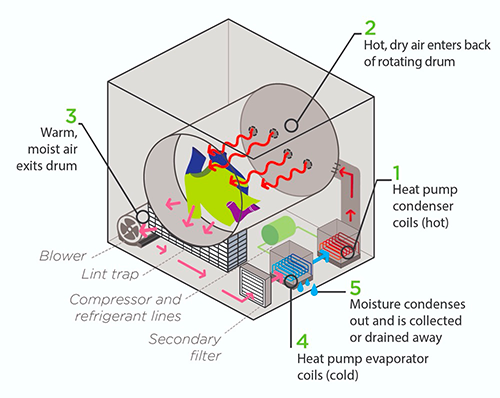

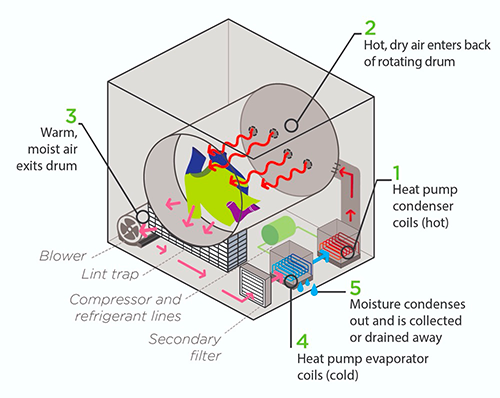

Heat pump dryers operate on the principle of heat transfer. They use a refrigerant to absorb heat from the environment and transfer it to the drying chamber. The process involves several key components:

1. Evaporator: The refrigerant enters the evaporator, where it absorbs heat from the air inside the dryer. As it absorbs heat, the refrigerant evaporates and turns into a gas.

2. Compressor: The gaseous refrigerant is then compressed, which increases its temperature and pressure. This high-temperature gas is then directed to the condenser.

3. Condenser: In the condenser, the hot gas releases its heat to the air in the drying chamber, warming the air and allowing it to absorb moisture from the food products. As the refrigerant cools, it condenses back into a liquid.

4. Expansion Valve: The liquid refrigerant then passes through an expansion valve, where its pressure drops, and it returns to the evaporator to repeat the cycle.

The Drying Process

The drying process in a heat pump dryer involves circulating warm, moist air through the food products. The warm air absorbs moisture from the food, and the moisture-laden air is then passed through the evaporator, where the moisture is removed. This cycle continues until the desired moisture content is achieved in the food products.

Advantages of Heat Pump Dryers for Food Processing

Energy Efficiency

One of the most significant advantages of heat pump dryers is their energy efficiency. By recycling air and using lower drying temperatures, heat pump dryers consume significantly less energy compared to traditional dryers. This is particularly important for food processing facilities looking to reduce operational costs.

Preservation of Nutritional Value

Heat pump dryers operate at lower temperatures, which helps preserve the nutritional value and flavor of the food products. High temperatures can degrade vitamins and other essential nutrients, making heat pump dryers a better choice for health-conscious consumers.

Versatility

Heat pump dryers can be used for a wide range of food products, including fruits, vegetables, herbs, and meats. This versatility makes them an ideal choice for food manufacturers looking to diversify their product offerings.

Reduced Environmental Impact

By using less energy and producing less waste heat, heat pump dryers have a lower environmental impact compared to traditional drying methods. This aligns with the growing trend towards sustainable and eco-friendly food processing practices.

Comparison with Traditional Drying Methods

Conventional Dryers

Traditional dryers, such as convection and drum dryers, rely on direct heat to evaporate moisture from food products. While they can be effective, they often consume more energy and can lead to uneven drying and loss of product quality.

Heat Pump Dryers

In contrast, heat pump dryers provide a more controlled drying environment. The ability to adjust temperature and humidity levels allows for more uniform drying, reducing the risk of over-drying or under-drying food products.

Applications of Heat Pump Dryers in Food Processing

Fruit and Vegetable Drying

Heat pump dryers are widely used for drying fruits and vegetables. The ability to maintain low temperatures helps retain the color, flavor, and nutritional value of the produce. Common applications include drying apples, bananas, tomatoes, and herbs. For instance, when drying apples, the heat pump dryer can maintain a temperature that prevents browning while effectively removing moisture.

Meat Drying

In the meat processing industry, heat pump dryers are used to produce dried meats such as jerky. The controlled drying process ensures that the meat is dried evenly, reducing the risk of spoilage and enhancing flavor. The low-temperature drying also helps in retaining the natural taste and texture of the meat, making it more appealing to consumers.

Snack Food Production

Heat pump dryers are also used in the production of snack foods, such as dried fruits and vegetable chips. The energy efficiency and quality preservation make them an attractive option for snack food manufacturers. For example, when producing vegetable chips, the heat pump dryer can create a crispy texture without the need for frying, resulting in a healthier snack option.

Herbal Drying

Herbs are another category of food products that benefit from heat pump drying. The gentle drying process helps preserve the essential oils and flavors of herbs, making them more potent and aromatic. This is particularly important for culinary herbs like basil, oregano, and thyme, which are often used in cooking.

Maintenance and Operation of Heat Pump Dryers

Regular Maintenance

To ensure optimal performance, regular maintenance of heat pump dryers is essential. This includes cleaning the evaporator and condenser coils, checking refrigerant levels, and inspecting electrical components. Regular maintenance not only prolongs the life of the dryer but also ensures that it operates at peak efficiency.

Operating Tips

1. Monitor Temperature and Humidity: Keeping track of the drying environment is crucial for achieving the desired moisture content in food products. Using sensors to monitor these parameters can help in making real-time adjustments.

2. Load Management: Avoid overloading the dryer to ensure proper air circulation and even drying. Proper load management helps in maximizing the efficiency of the drying process.

3. Use Quality Ingredients: Starting with high-quality raw materials will result in better final products. Ensuring that the food products are fresh and free from defects will enhance the overall quality of the dried goods.

4. Regular Calibration: Periodically calibrating the temperature and humidity controls can help maintain consistent drying conditions, leading to better product quality.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology. Their energy efficiency, ability to preserve nutritional value, and versatility make them an excellent choice for food manufacturers. As the demand for sustainable and high-quality food products continues to grow, heat pump dryers will play an increasingly important role in the food processing industry.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer for food processing?

The main advantage is energy efficiency, as heat pump dryers consume less energy compared to traditional dryers while preserving the nutritional value of the food.

2. Can heat pump dryers be used for all types of food?

Yes, heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and snacks.

3. How does a heat pump dryer differ from a conventional dryer?

Heat pump dryers recycle air and operate at lower temperatures, while conventional dryers rely on direct heat, which can lead to higher energy consumption and potential loss of product quality.

4. What maintenance is required for heat pump dryers?

Regular maintenance includes cleaning the evaporator and condenser coils, checking refrigerant levels, and inspecting electrical components.

5. What types of food products are commonly dried using heat pump dryers?

Commonly dried products include fruits (like apples and bananas), vegetables (like tomatoes), meats (like jerky), and herbs (like basil and thyme).