Content Menu

● Introduction to Room Type Drying Machines

>> Components of Room Type Drying Machines

● Types of Room Type Drying Machines

>> Batch Type Fruits and Vegetable Dryer

>> Large Industrial Food Dehydrator Machine

>> Conveyor Mesh Belt Industrial Food Dryer

● How Room Type Drying Machines Work

● Benefits of Room Type Drying Machines

● Applications of Room Type Drying Machines

● Maintenance and Troubleshooting

● Future Developments

● Conclusion

● FAQ

>> 1. What are the main components of a room type drying machine?

>> 2. How do room type drying machines work?

>> 3. What types of food can be dried using room type drying machines?

>> 4. What are the benefits of using room type drying machines?

>> 5. Are room type drying machines suitable for large-scale production?

● Citations:

Food drying machines have become essential in the food industry for preserving a wide range of products, from fruits and vegetables to meats and herbs. Among these machines, room type drying machines are particularly versatile and efficient, offering both batch and continuous drying options. In this article, we will delve into the technology behind room type drying machines, exploring their components, operation, and benefits.

Introduction to Room Type Drying Machines

Room type drying machines are designed to handle large quantities of food products by circulating warm air around them, gradually reducing moisture content without cooking the food. This method is crucial for preserving nutritional value and extending shelf life. These machines are widely used in various sectors, including the food processing industry, pharmaceutical industry, and agricultural sector.

Components of Room Type Drying Machines

1. Heat Source: These machines often use electric heaters, gas heaters, or heat pumps to generate the necessary warmth for drying. Heat pumps are particularly popular due to their energy efficiency and ability to maintain a consistent temperature.

2. Air Circulation System: Fans are used to distribute the heated air evenly throughout the drying chamber. This ensures that all food items are exposed to the same drying conditions, resulting in uniform drying.

3. Trays or Conveyors: Depending on the design, food is placed on trays for batch drying or on conveyor belts for continuous drying. Trays are ideal for delicate items, while conveyor belts are better suited for high-volume production.

4. Control Panel: This allows operators to set temperature, humidity, and drying time according to the type of food being processed. Modern control panels often include advanced features like automatic temperature control and moisture monitoring.

Types of Room Type Drying Machines

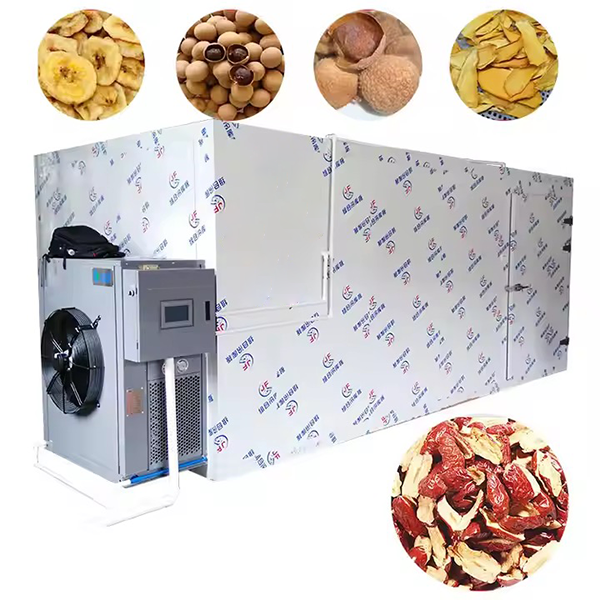

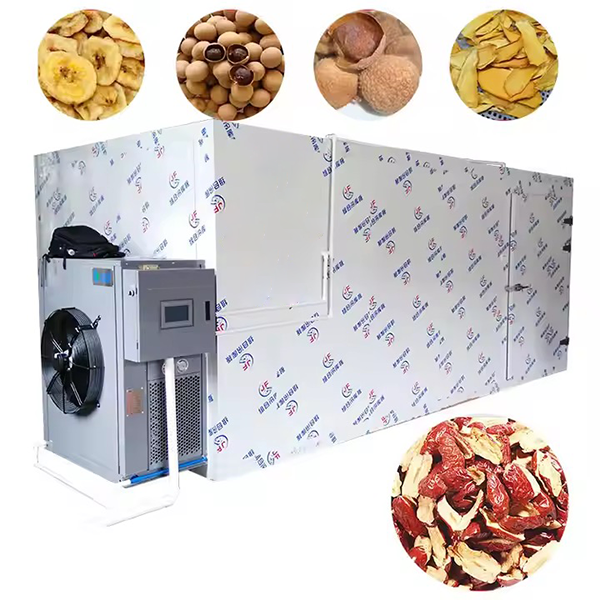

Batch Type Fruits and Vegetable Dryer

These machines use heat pumps and can handle batches of 150 to 300 kg. They are automatic, featuring multiple trays, and require a power rating of 8 kW. This type is ideal for small to medium-scale operations, such as local farms or small food processors.

Large Industrial Food Dehydrator Machine

With capacities of up to 350 kg per batch, these machines are equipped with numerous trays and require higher power inputs, typically around 20 kW. They are suited for large-scale food processing facilities where high volume production is necessary.

Conveyor Mesh Belt Industrial Food Dryer

These are continuous drying machines ideal for high-volume production. They can be customized to meet specific production needs and are used for drying a variety of foods, including vegetables, fruits, and seafood. The mesh belt design allows for efficient air circulation and prevents food from sticking to the surface.

How Room Type Drying Machines Work

The operation of room type drying machines involves several key steps:

1. Loading: Food items are placed on trays or conveyor belts.

2. Heating: The machine generates heat using its heat source.

3. Air Circulation: Fans distribute the heated air throughout the drying chamber.

4. Moisture Removal: As the hot air circulates, moisture is evaporated from the food.

5. Unloading: Once the desired dryness level is achieved, the food is removed from the machine.

Benefits of Room Type Drying Machines

1. Energy Efficiency: Many modern designs incorporate energy-saving technologies, such as heat pumps, which reduce energy consumption and lower operational costs.

2. Uniform Drying: The controlled environment ensures that food is dried uniformly, maintaining quality and texture.

3. Versatility: These machines can be used for a wide range of food products, from fruits and vegetables to meats and herbs.

4. Cost-Effective: By extending shelf life, these machines help reduce food waste and increase profitability for producers.

Applications of Room Type Drying Machines

Room type drying machines are used in various sectors:

1. Food Processing Industry: For drying fruits, vegetables, meats, and herbs. This helps preserve nutritional value and flavor.

2. Pharmaceutical Industry: For drying medicinal herbs and plants. The controlled drying conditions ensure the preservation of active ingredients.

3. Agricultural Sector: To preserve agricultural products and extend their shelf life, reducing waste and increasing market availability.

Maintenance and Troubleshooting

Regular maintenance is crucial for ensuring the longevity and efficiency of room type drying machines. This includes cleaning the machine regularly, checking for worn-out parts, and ensuring proper calibration of the control panel. Common issues such as uneven drying or reduced airflow can often be resolved by adjusting fan settings or cleaning air vents.

Future Developments

As technology advances, room type drying machines are likely to incorporate more sophisticated features, such as advanced moisture sensors and AI-driven control systems. These developments will further enhance efficiency and product quality, making these machines even more indispensable in the food industry.

Conclusion

Room type drying machines are a crucial component in the food industry, offering efficient and cost-effective solutions for preserving a wide range of food products. Their versatility, energy efficiency, and ability to maintain product quality make them an essential tool for both small-scale and large-scale food processing operations.

FAQ

1. What are the main components of a room type drying machine?

The main components include a heat source, air circulation system, trays or conveyors, and a control panel.

2. How do room type drying machines work?

They work by circulating heated air around the food to remove moisture, using a combination of heating and air circulation.

3. What types of food can be dried using room type drying machines?

These machines can dry a variety of foods, including fruits, vegetables, meats, herbs, and even dairy products.

4. What are the benefits of using room type drying machines?

Benefits include energy efficiency, uniform drying, versatility, and cost-effectiveness.

5. Are room type drying machines suitable for large-scale production?

Yes, they are suitable for both small-scale and large-scale production, with options for batch and continuous drying.

Citations:

[1] https://itpo-tokyo.unido.org/en/technology_db/6436/

[2] https://www.bxdryer.com/news/industry-news/how-food-dehydrator-works-news.html

[3] https://www.dryeratech.com/room-type-drying-machines-a-comprehensive-guide.html

[4] https://www.alamy.com/stock-photo/drying-machine.html

[5] https://www.youtube.com/watch?v=A5Nf2P7-nbU

[6] https://www.istockphoto.com/photos/dehydrator

[7] https://www.ikemachinery.com/food-drying-machine/

[8] https://foodtechprojects.com/understand-the-work-process-of-industrial-food-dryer-machine/

[9] https://airtekdehydrator.com/blog/types-commercial-food-dehydrators/

[10] https://www.alibaba.com/showroom/food-dryer-machine-pictures.html

[11] https://www.youtube.com/watch?v=XKfu171vv-E

[12] https://www.istockphoto.com/photos/food-dehydrator

[13] https://www.fox-foodprocessinginabox.eu/drying-technologies/

[14] https://aradmachineryco.com/article/Food-dehydrator-buying-guide