Content Menu

● Understanding Heat Pumps

>> How Heat Pumps Work

● Advantages of Heat Pump Dryers for Food

● Applications of Heat Pump Dryers in Food Processing

● Key Features to Look for in Heat Pump Dryers

● Maintenance Tips for Heat Pump Dryers

● Energy Efficiency in Food Drying

● Economic Benefits of Heat Pump Technology

● Innovations in Heat Pump Technology

● Environmental Impact of Heat Pump Dryers

● Conclusion

● FAQ

>> 1. What types of foods can be dried using a heat pump dryer?

>> 2. How does a heat pump dryer compare to traditional dryers?

>> 3. Are there any specific maintenance requirements for heat pump dryers?

>> 4. Can I use a heat pump dryer for large-scale operations?

>> 5. What should I consider when purchasing a heat pump dryer?

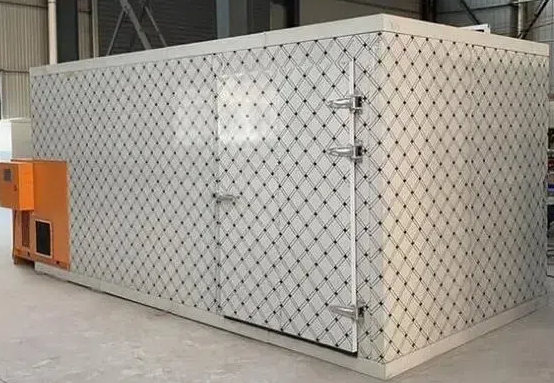

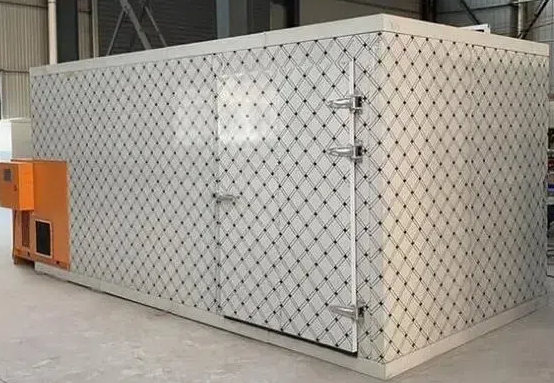

In recent years, the food drying industry has seen significant advancements in technology, particularly with the introduction of heat pump dryers. These machines are revolutionizing the way food is dried, offering energy efficiency and superior drying capabilities. This article will delve into what a heat pump is, how it works, and its benefits in the context of food drying.

Understanding Heat Pumps

A heat pump is a device that transfers heat from one place to another using a refrigeration cycle. In the context of dryers, it extracts heat from the air or the environment and uses it to dry food products. Unlike traditional dryers that generate heat through electric resistance or gas combustion, heat pumps recycle existing heat, making them more energy-efficient.

How Heat Pumps Work

Heat pumps operate on a simple principle: they move heat rather than generate it. This process involves several key components:

- Evaporator: The evaporator absorbs heat from the air or environment. In a dryer, this is where moisture from the food is also extracted.

- Compressor: The compressor increases the temperature and pressure of the refrigerant gas, which is crucial for transferring heat.

- Condenser: The condenser releases the absorbed heat into the drying chamber, warming the air that circulates around the food.

- Expansion Valve: This component reduces the pressure of the refrigerant, allowing it to cool before returning to the evaporator.

This cyclical process allows heat pumps to maintain a consistent drying temperature while minimizing energy consumption.

Advantages of Heat Pump Dryers for Food

Heat pump dryers offer numerous advantages over traditional drying methods:

- Energy Efficiency: Heat pump dryers use significantly less energy than conventional dryers. They can reduce energy consumption by up to 50%, making them an environmentally friendly option.

- Gentle Drying: The lower temperatures used in heat pump drying help preserve the quality and nutritional value of food. This is particularly important for delicate items like fruits and herbs.

- Consistent Results: Heat pumps provide uniform drying conditions, reducing the risk of over-drying or under-drying food products.

- Versatility: These dryers can handle a wide range of food products, from fruits and vegetables to meats and fish.

- Reduced Environmental Impact: By using less energy and producing fewer emissions, heat pump dryers contribute to a more sustainable food processing industry.

Applications of Heat Pump Dryers in Food Processing

Heat pump dryers are versatile machines used in various applications within the food industry:

- Fruit Drying: Heat pumps are ideal for drying fruits like apples, bananas, and berries. The gentle drying process helps retain color, flavor, and nutrients.

- Vegetable Drying: Vegetables such as carrots, peas, and bell peppers can be effectively dried using heat pumps without losing their texture or taste.

- Herb Drying: Herbs require careful drying to preserve their essential oils and flavors. Heat pump dryers provide optimal conditions for this process.

- Meat and Fish Drying: Heat pumps can also be used for drying meat and fish products, ensuring safety while maintaining quality.

Key Features to Look for in Heat Pump Dryers

When selecting a heat pump dryer for your food processing needs, consider the following features:

- Temperature Control: Look for models with precise temperature control to ensure optimal drying conditions for different types of food.

- Airflow Management: Effective airflow systems help ensure uniform drying and prevent hotspots that could lead to uneven results.

- Energy Efficiency Rating: Choose models with high energy efficiency ratings to maximize savings on operational costs.

- Ease of Use: User-friendly controls and automation features can streamline your drying processes.

Maintenance Tips for Heat Pump Dryers

To ensure your heat pump dryer operates efficiently and lasts longer, follow these maintenance tips:

1. Regular Cleaning: Keep filters and condensers clean to maintain airflow and efficiency.

2. Check Seals: Inspect door seals regularly to prevent leaks that could affect performance.

3. Monitor Temperature Settings: Ensure temperature settings are appropriate for the type of food being dried.

4. Schedule Professional Servicing: Regular professional maintenance can help identify potential issues before they become major problems.

Energy Efficiency in Food Drying

One of the most significant benefits of using heat pump dryers is their energy efficiency. In an age where sustainability is paramount, reducing energy consumption not only lowers operational costs but also minimizes environmental impact.

Heat pump dryers typically operate at lower temperatures compared to traditional methods. This not only conserves energy but also preserves more nutrients in dried foods. For instance, while traditional methods might require temperatures exceeding 70°C (158°F), heat pumps often operate between 30°C (86°F) and 60°C (140°F), which is ideal for maintaining flavor and nutritional integrity.

Economic Benefits of Heat Pump Technology

Investing in a heat pump dryer can yield substantial economic benefits over time. Although the initial investment may be higher than traditional dryers, the long-term savings on energy bills can offset this cost significantly.

Moreover, because these dryers promote better quality products with enhanced flavors and nutrients, businesses can often command higher prices for their dried goods. This competitive edge can lead to increased sales volumes and improved profit margins.

Innovations in Heat Pump Technology

The field of heat pump technology is constantly evolving. Recent innovations include:

- Smart Technology Integration: Many modern heat pump dryers now come equipped with smart technology that allows users to monitor and control settings remotely via smartphone apps. This feature enhances convenience and ensures optimal operation at all times.

- Enhanced Sensors: Advanced sensors can detect moisture levels in real-time, adjusting temperature and airflow automatically to optimize drying efficiency.

- Modular Designs: New modular designs allow businesses to scale their operations easily by adding additional units as demand increases without requiring a complete system overhaul.

Environmental Impact of Heat Pump Dryers

The environmental benefits of using heat pump dryers extend beyond just reduced energy consumption. These systems produce fewer greenhouse gas emissions compared to traditional methods that rely on fossil fuels or high-energy electricity sources.

Additionally, because they preserve more nutrients during the drying process, they contribute to reducing food waste—a significant issue in many parts of the world. By maximizing yield from raw materials, businesses can help combat hunger while promoting sustainability.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology. Their energy efficiency, gentle drying capabilities, and versatility make them an excellent choice for various applications in the food industry. As demand for sustainable practices grows, investing in heat pump technology can provide both economic benefits and environmental advantages while ensuring high-quality dried products that meet consumer expectations.

FAQ

1. What types of foods can be dried using a heat pump dryer?

Heat pump dryers can effectively dry a wide range of foods including fruits, vegetables, herbs, meats, and fish while preserving their quality and nutritional value.

2. How does a heat pump dryer compare to traditional dryers?

Heat pump dryers are more energy-efficient than traditional dryers as they recycle existing heat rather than generating new heat. This leads to lower energy consumption and better preservation of food quality.

3. Are there any specific maintenance requirements for heat pump dryers?

Yes, regular cleaning of filters and condensers is essential. Additionally, checking seals and monitoring temperature settings will help maintain optimal performance.

4. Can I use a heat pump dryer for large-scale operations?

Absolutely! Many manufacturers offer industrial-sized models designed specifically for large-scale food processing operations while maintaining efficiency.

5. What should I consider when purchasing a heat pump dryer?

Key considerations include temperature control features, airflow management systems, energy efficiency ratings, and user-friendly operation controls.