Content Menu

● Introduction to Cabinet Type Dehydrators

● Advantages of Cabinet Type Dehydrators

● Key Factors to Consider

● Types of Food Dehydrators

● Applications of Cabinet Dehydrators

● Components and Design

● Operation and Maintenance

● Advanced Technologies in Cabinet Dehydrators

● Conclusion

● FAQ

>> 1. What is a cabinet type dehydrator?

>> 2. What are the benefits of using a cabinet dehydrator?

>> 3. How do I choose the right cabinet dehydrator for my needs?

>> 4. What types of food can I dehydrate in a cabinet dehydrator?

>> 5. How do I maintain a cabinet dehydrator?

● Citations:

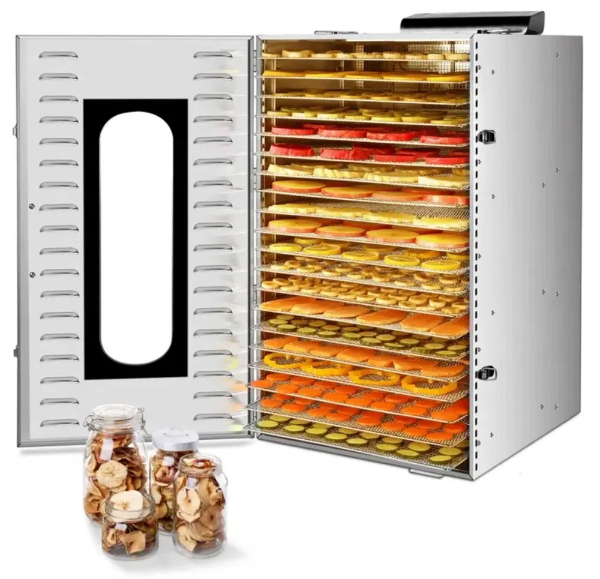

Introduction to Cabinet Type Dehydrators

A cabinet type dehydrator is a specialized piece of equipment designed to remove moisture from food products, thereby extending their shelf life while preserving their natural flavors, colors, and essential nutrients. These machines, also known as box-type dehydrators or vertical airflow dehydrators (though the airflow can often be horizontal or a combination), are characterized by their enclosed design. This design often integrates a heat pump dryer with a controlled chamber to optimize performance and maximize energy efficiency. Cabinet dehydrators offer superior control and consistency compared to simpler dehydrators, making them suitable for commercial applications and even discerning home use. The controlled environment ensures consistent drying, resulting in high product quality and minimal waste. These dehydrators are essential for businesses looking to expand their capabilities, reduce waste, and ensure high-quality results.

Advantages of Cabinet Type Dehydrators

Cabinet dehydrators offer a compelling array of advantages that make them a superior choice for many applications:

-Consistent Drying: They ensure uniform dehydration due to controlled temperature and airflow, leading to consistent product quality. This is crucial for maintaining brand reputation and meeting customer expectations. The ability to replicate drying cycles ensures each batch meets the same standards.

-Energy Efficiency: These dehydrators optimize energy use by integrating a heat pump dryer and minimizing heat loss through insulation. This results in lower operating costs and a smaller environmental footprint, appealing to businesses focused on sustainability.

-Large Capacity: Suited for processing significant quantities of food, making them ideal for commercial operations. This high throughput translates to increased productivity and profitability, enabling businesses to meet high demand.

-Versatility: They can be used for various food products, from fruits and vegetables to meats and herbs. This adaptability allows businesses to diversify their product offerings and cater to a wider range of customer preferences.

-User-Friendly: Simple to operate with minimal setup, allowing for efficient and hassle-free operation. Intuitive controls and automated processes minimize the need for specialized training, reducing labor costs and potential errors.

-No Tray Rotation: Even airflow eliminates the need to manually rotate trays during drying, saving time and effort. This feature streamlines the drying process, freeing up personnel for other tasks and improving overall efficiency.

Key Factors to Consider

When choosing a cabinet type dehydrator, consider these factors to ensure you select the best model for your specific needs:

-Capacity: Determine the volume of food you need to dehydrate per batch and choose a model with sufficient tray space. Cabinet dryers can handle volumes ranging from approximately 30 kg to over 1 ton per shift. Consider future growth when assessing capacity requirements.

-Temperature Range: Ensure the dehydrator can reach the temperatures required for different types of food, with adjustable settings for optimal results. Precise temperature control is essential for preserving the quality and nutritional value of various foods.

-Airflow System: Look for a system that provides even air distribution throughout the cabinet to prevent hot spots and ensure uniform drying. A well-designed airflow system ensures that every part of the food receives consistent heat, preventing uneven drying and potential spoilage.

-Material Quality: Choose machines made from durable, food-grade materials like stainless steel, which are easy to clean and resistant to corrosion. Stainless steel is hygienic, easy to sanitize, and built to withstand the rigors of commercial use.

-Energy Efficiency: Consider the energy consumption of the dehydrator to minimize operating costs and reduce environmental impact. Look for models with advanced insulation, efficient heating elements, and smart energy management systems.

-Ease of Cleaning: Opt for models with removable, dishwasher-safe parts for easy cleaning and maintenance. Easy-to-clean components reduce downtime and minimize the risk of contamination.

-Control Features: Advanced models offer precise control over temperature and humidity, allowing fine-tuning of the drying process. Digital controls, programmable settings, and real-time monitoring provide greater precision and flexibility in the drying process.

-Insulation: Adequate insulation of the drying chamber ensures minimal heat loss. The higher the insulation rating, the more energy-efficient the appliance. Insulation material must be food-grade and capable of withstanding high temperatures.

-Ventilation: Proper ventilation ensures moisture is efficiently removed from the chamber. Adjustable vents or automated humidity control can optimize drying conditions.

-Warranty and Support: Check the warranty offered by the manufacturer and ensure they provide adequate technical support. A reliable warranty protects your investment and provides peace of mind.

Types of Food Dehydrators

The two main styles of food dehydrators are horizontal and vertical airflow models, though cabinet models often employ a hybrid approach:

-Horizontal Airflow: The heating element and fan are positioned on the side or back of the unit. This design reduces flavor mixing between different foods, provides equal heat exposure to all trays, and prevents liquids from dripping onto the heating element. Horizontal airflow dehydrators are generally more efficient and produce more consistent results than vertical airflow models, making them ideal for commercial applications.

-Vertical Airflow: The heating element and fan are positioned at the bottom or top of the unit. While often more compact and affordable, they may not provide as even drying as horizontal airflow dehydrators. Trays closest to the heat source tend to dry faster, requiring manual tray rotation. This type is less common in large cabinet models due to the inefficiency of drying.

Applications of Cabinet Dehydrators

Cabinet dehydrators are versatile tools with a wide range of applications across various industries:

-Food Processing: Used to create dehydrated products like dried fruits, vegetable chips, fruit leathers, and meat jerky. They allow for the consistent production of high-quality dehydrated snacks and ingredients.

-Agriculture: Farmers use cabinet dehydrators to preserve crops and reduce post-harvest losses. Dehydration extends the shelf life of perishable produce, allowing farmers to sell their products for longer periods and reduce waste.

-Herbal Medicine: These dehydrators are used to dry herbs and medicinal plants while preserving their active compounds. Controlled drying conditions are crucial for preserving the potency and efficacy of medicinal herbs.

-Pet Food Industry: They produce dried pet treats and chews, ensuring safety and extending shelf life. Dehydrated pet treats are a healthy and natural alternative to processed pet foods.

-Research and Development: Laboratories use cabinet dehydrators for sample preparation and materials testing. Precise control over temperature and humidity is essential for accurate and repeatable results.

-Restaurant Industry: Restaurants use cabinet dehydrators to create unique menu items, such as dehydrated garnishes, crispy vegetable chips, and flavorful meat jerky. They allow chefs to add innovative and healthy options to their menus.

-Snack Food Production: Companies specializing in snack foods rely on cabinet dehydrators for high-volume production of dried fruit snacks, vegetable crisps, and other healthy snack alternatives.

-Ingredient Manufacturing: Food ingredient manufacturers utilize dehydrators to produce dried vegetable powders, herb blends, and other ingredients for use in processed foods and culinary applications.

Components and Design

A cabinet type dehydrator typically includes:

-Insulated Cabinet: An enclosed structure to minimize heat loss and maintain a stable internal environment. Insulation materials are often food-grade and designed to withstand high temperatures.

-Heating Element: Provides the heat necessary for evaporating moisture from the food. Heating elements can be electric resistance coils, infrared lamps, or heat pumps, each with its own advantages in terms of efficiency and temperature control.

-Fan: Circulates hot air throughout the cabinet, ensuring even drying. Fans are designed for consistent airflow and can be adjustable to accommodate different types of food.

-Trays: Hold the food items during the dehydration process. Trays are typically made of stainless steel or food-grade plastic and are designed for easy loading and unloading.

-Control Panel: Allows users to set and monitor temperature, humidity, and drying time. Control panels can range from simple analog dials to sophisticated digital interfaces with programmable settings.

-Airflow System: Ensures consistent air circulation to prevent hot spots and uneven drying. Airflow systems often include baffles, ducts, and adjustable vents to optimize air distribution.

-Humidity Control: Measures and regulates the moisture content within the dehydrator. Automated humidity control can optimize drying conditions and improve the quality of dehydrated products.

-Sensors: Monitor temperature, humidity, and airflow to ensure consistent drying conditions. Sensors provide real-time data that is used to adjust settings and optimize performance.

-Safety Features: Overheat protection, automatic shut-off, and other safety features protect the user and prevent damage to the machine. Safety features are essential for ensuring safe and reliable operation.

Operation and Maintenance

Operating a cabinet dehydrator is straightforward, but following best practices ensures optimal results:

1. Preparation: Clean and prepare the food items by slicing, dicing, or marinating as needed. Uniform slicing ensures even drying.

2. Loading: Arrange the food items in a single layer on the trays, ensuring proper spacing for airflow. Overcrowding the trays can impede airflow and result in uneven drying.

3. Settings: Set the desired temperature and drying time according to the food type and recipe. Consult a dehydration guide or recipe book for recommended settings.

4. Monitoring: Periodically check the food to ensure even drying and adjust settings as needed. Drying times can vary depending on the moisture content of the food and the ambient humidity.

5. Cooling and Storage: Once drying is complete, allow the food to cool before storing it in airtight containers. Proper cooling prevents condensation and extends the shelf life of the dehydrated food.

Maintenance tips:

-Cleaning: Regularly clean the trays and interior of the dehydrator to prevent the buildup of food particles and bacteria. Use a mild detergent and warm water for cleaning.

-Inspection: Inspect the heating element, fan, and control panel for any signs of damage or wear. Replace any worn or damaged parts immediately.

-Calibration: Calibrate the temperature and humidity sensors periodically to ensure accurate readings. Calibration ensures that the dehydrator is operating within the specified parameters.

-Storage: Store the dehydrator in a clean, dry place when not in use. Protect the dehydrator from dust, moisture, and extreme temperatures.

-Filter Replacement: If your dehydrator has air filters, replace them regularly to maintain optimal airflow and prevent dust buildup.

-Lubrication: Lubricate moving parts, such as fan motors, according to the manufacturer's instructions. Lubrication prevents friction and extends the lifespan of the components.

Advanced Technologies in Cabinet Dehydrators

Modern cabinet dehydrators often incorporate advanced technologies to enhance their performance and usability:

-Heat Pump Technology: Utilizes a refrigeration cycle to extract heat from the air and transfer it to the drying chamber, resulting in significant energy savings compared to traditional heating elements.

-Smart Controls: Features intelligent control systems that automatically adjust temperature, humidity, and airflow based on the type of food being dehydrated.

-Data Logging: Records data on temperature, humidity, and drying time, allowing users to track and optimize their drying processes.

-Remote Monitoring: Enables users to monitor and control the dehydrator from a remote location using a smartphone or computer.

-Automated Cleaning: Incorporates self-cleaning systems that automatically remove food debris and sanitize the interior of the dehydrator.

-Vacuum Dehydration: In some advanced models, a vacuum environment is created to lower the boiling point of water, enabling faster drying at lower temperatures and preserving delicate flavors and nutrients.

Conclusion

Cabinet type dehydrators are essential for food processing, agriculture, and more, offering efficient and consistent dehydration for various products. Whether for commercial operations or discerning home use, they offer unparalleled control and consistency. When selecting a cabinet dehydrator, careful consideration of capacity, temperature range, airflow, material quality, and other key factors will ensure that the chosen model meets the specific needs of the application. The advanced technologies incorporated into modern dehydrators further enhance their performance, usability, and energy efficiency. These units are a worthwhile investment for businesses looking to expand their capabilities, reduce waste, and ensure high-quality results.

FAQ

1. What is a cabinet type dehydrator?

A cabinet type dehydrator is a self-contained unit designed to remove moisture from food products, extending their shelf life while preserving flavor and nutrients. These machines feature an integrated design with a heat pump dryer and a controlled chamber for optimal performance and energy efficiency. They are available in various sizes and configurations to suit different applications.

2. What are the benefits of using a cabinet dehydrator?

Cabinet dehydrators offer consistent drying, energy efficiency, large capacity, versatility, and user-friendly operation. They ensure uniform dehydration due to controlled temperature and airflow, making them suitable for commercial operations and diverse food products. The ability to process large quantities of food efficiently and consistently makes them a valuable asset for many businesses.

3. How do I choose the right cabinet dehydrator for my needs?

Consider factors such as capacity, temperature range, airflow system, material quality, energy efficiency, ease of cleaning, and control features. Assess your production volume and ensure the dehydrator can reach the temperatures needed for different food types. Consider your long-term needs and choose a model that can accommodate future growth.

4. What types of food can I dehydrate in a cabinet dehydrator?

Cabinet dehydrators are versatile and can dehydrate a wide variety of foods, including fruits, vegetables, meats, herbs, and more. The consistent temperature and airflow allow you to dehydrate different food types with predictable results. Experimenting with different foods and recipes can lead to new and exciting product offerings.

5. How do I maintain a cabinet dehydrator?

Regularly clean the trays and interior, inspect the heating element and fan, calibrate the sensors, and store the dehydrator in a clean, dry place when not in use. Proper maintenance ensures optimal performance and prolongs the lifespan of the machine. Following the manufacturer's maintenance schedule is crucial for keeping the dehydrator in good working order.

Citations:

[1] https://www.dryeratech.com/the-ultimate-guide-to-cabinet-type-dehydrator-machines.html

[2] https://patents.google.com/patent/CN110207480A/zh

[3] https://www.dryeratech.com/how-to-choose-the-right-cabinet-type-dehydrator-for-your-needs.html

[4] https://patents.google.com/patent/CN1110593C/zh

[5] https://www.foodandwine.com/lifestyle/kitchen/best-food-dehydrators

[6] https://shop.howlifeusa.com/zh/washing-machine/

[7] https://www.thespruceeats.com/best-food-dehydrators-4077285