Content Menu

● Introduction to Modern Fruit Drying Technology

● The Advantages of Modern Fruit Dryer Machines

>> Energy Efficiency and Sustainability

>> Precision and Consistency

>> Increased Capacity and Productivity

>> Versatility and Adaptability

● Technological Innovations in Fruit Drying

>> Automatic Fruit Dehydration Technology

>> Smart Sensors and IoT Integration

>> Hybrid Drying Technologies

● Applications Across Industries

>> Food and Beverage Sector

>> Nutraceuticals and Dietary Supplements

>> Cosmetics and Personal Care

● The Future of Fruit Drying Technology

>> Artificial Intelligence and Machine Learning

>> Sustainable and Eco-friendly Solutions

>> Nanotechnology in Fruit Preservation

● Choosing the Right Fruit Dryer Machine

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using a modern fruit dryer machine?

>> 2. How do automatic fruit dehydration technologies improve the drying process?

>> 3. What factors should be considered when choosing a fruit dryer machine for commercial use?

>> 4. How are smart sensors and IoT integration improving fruit drying technology?

>> 5. What are some emerging trends in fruit drying technology?

Introduction to Modern Fruit Drying Technology

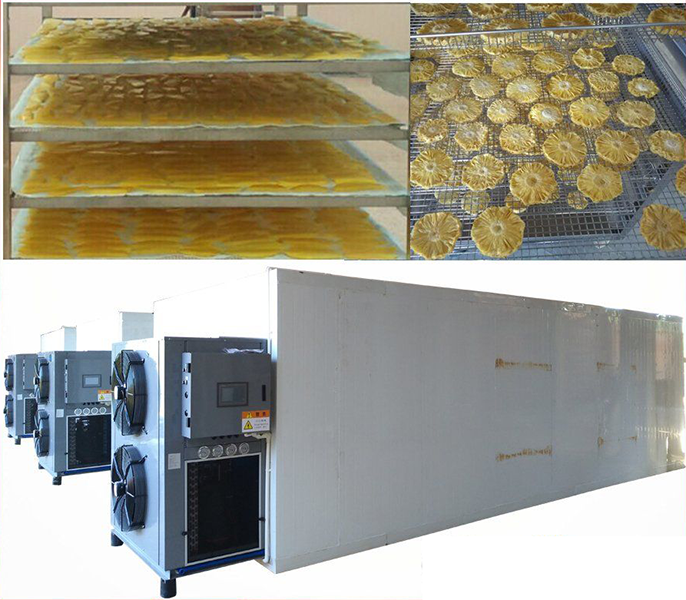

In recent years, the food processing industry has witnessed a significant transformation, particularly in the realm of fruit preservation. At the forefront of this revolution are China's advanced fruit dryer machines, which have redefined the standards for efficiency, quality, and innovation in food dehydration. These industrial fruit dehydrators have become indispensable tools for businesses looking to extend the shelf life of fruits while maintaining their nutritional value and flavor profiles.

The evolution of fruit drying technology has come a long way from traditional sun-drying methods. Today's commercial vegetable drying equipment incorporates cutting-edge features that ensure precision, consistency, and energy efficiency. These advancements have not only improved the quality of dried fruits but have also opened up new possibilities for product diversification and market expansion.

The Advantages of Modern Fruit Dryer Machines

Energy Efficiency and Sustainability

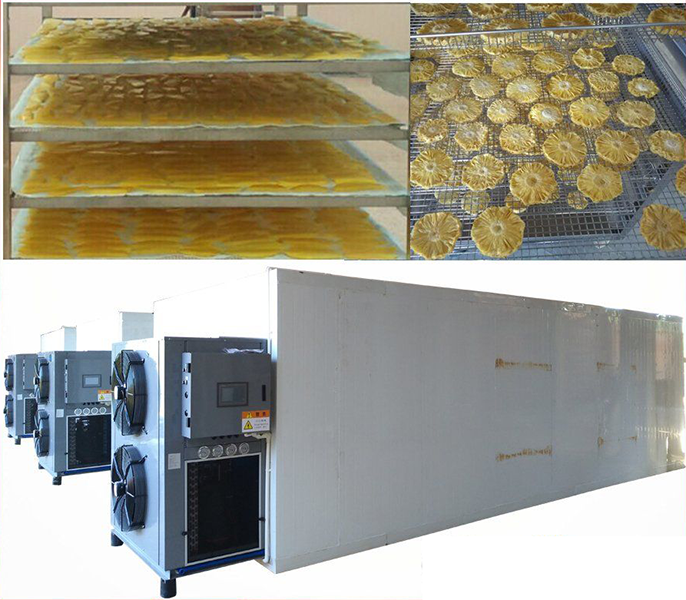

One of the most significant benefits of contemporary fruit dryer machines is their energy efficiency. Manufacturers in China have prioritized the development of energy-efficient food dryers that minimize power consumption without compromising on performance. These machines often incorporate heat recovery systems and advanced insulation materials, resulting in reduced operating costs and a smaller carbon footprint.

Precision and Consistency

Stainless steel fruit processing machines are designed to deliver precise and consistent results. With digital controls and sensors, these devices can maintain optimal temperature and humidity levels throughout the drying process. This level of control ensures that each batch of dried fruit meets the highest quality standards, with uniform moisture content and preserved nutritional value.

Increased Capacity and Productivity

High-capacity fruit dryers have revolutionized large-scale fruit processing operations. These multi-layer fruit drying systems can handle substantial volumes of fruits simultaneously, significantly boosting productivity. With the ability to process various types of fruits concurrently, businesses can diversify their product lines and meet the growing market demand for dried fruit products.

Versatility and Adaptability

Modern fruit and vegetable drying solutions offer unprecedented versatility. These machines can be easily adjusted to accommodate different types of fruits, vegetables, and even herbs. This adaptability allows food processors to expand their product range and cater to diverse consumer preferences without the need for multiple specialized machines.

Technological Innovations in Fruit Drying

Automatic Fruit Dehydration Technology

The integration of automation in fruit drying processes has been a game-changer for the industry. Automatic fruit dehydration technology minimizes human intervention, reducing the risk of contamination and ensuring consistent quality across batches. These systems can handle everything from fruit preparation to packaging, streamlining the entire production process.

Smart Sensors and IoT Integration

Smart fruit drying technology leverages the power of the Internet of Things (IoT) to enhance monitoring and control capabilities. Advanced sensors continuously track various parameters such as temperature, humidity, and air flow. This data is then used to optimize the drying process in real-time, ensuring the best possible results while minimizing energy consumption.

Hybrid Drying Technologies

Innovative hybrid drying systems combine multiple drying methods to achieve superior results. For instance, some advanced food preservation equipment may integrate convection heating with microwave or infrared technologies. This combination can significantly reduce drying times while preserving the fruit's color, flavor, and nutritional content.

Applications Across Industries

Food and Beverage Sector

The primary application of fruit dryer machines is in the food and beverage industry. Dried fruits are used in a wide range of products, including:

- Snack foods

- Breakfast cereals

- Baked goods

- Trail mixes

- Fruit teas

The ability to produce high-quality dried fruits at scale has enabled manufacturers to meet the growing consumer demand for healthy, convenient snack options.

Nutraceuticals and Dietary Supplements

The nutraceutical industry has also benefited from advancements in fruit drying technology. Dried fruit powders and extracts are increasingly used in dietary supplements, owing to their concentrated nutritional profiles. The precision offered by modern fruit dryers ensures that these products retain maximum nutritional value, making them ideal for health-conscious consumers.

Cosmetics and Personal Care

Dried fruit extracts have found their way into the cosmetics and personal care industry. These natural ingredients are prized for their antioxidant properties and are used in various skincare and haircare products. The ability to produce high-quality, contaminant-free dried fruit ingredients has opened up new opportunities for natural and organic beauty brands.

The Future of Fruit Drying Technology

Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning algorithms is set to revolutionize fruit drying processes further. These technologies can analyze vast amounts of data to optimize drying parameters, predict maintenance needs, and even suggest improvements to product quality based on historical performance.

Sustainable and Eco-friendly Solutions

As environmental concerns continue to grow, the focus on developing sustainable fruit drying solutions is intensifying. Future innovations are likely to include:

- Solar-powered drying systems

- Biodegradable packaging solutions

- Water recycling technologies

- Zero-waste processing methods

These advancements will not only reduce the environmental impact of fruit drying operations but also appeal to eco-conscious consumers.

Nanotechnology in Fruit Preservation

Nanotechnology holds promising potential for the future of fruit preservation. Researchers are exploring the use of nanoparticles to enhance the drying process, improve food safety, and extend shelf life even further. This cutting-edge technology could lead to the development of "smart" packaging that actively preserves dried fruits and indicates freshness levels.

Choosing the Right Fruit Dryer Machine

When selecting a fruit dryer machine for commercial use, several factors should be considered:

1. Capacity requirements

2. Energy efficiency ratings

3. Versatility and adaptability

4. Automation features

5. Quality control mechanisms

6. Maintenance and support services

It's essential to partner with reputable manufacturers who offer comprehensive after-sales support and have a track record of innovation in the field.

Conclusion

The advancements in China's fruit dryer machines have ushered in a new era of food preservation technology. These innovative solutions offer unprecedented efficiency, quality, and versatility, enabling businesses to meet the growing global demand for dried fruit products. As technology continues to evolve, we can expect even more exciting developments in the field of fruit drying, further enhancing our ability to preserve nature's bounty for year-round enjoyment.

By embracing these technological advancements, food processors can not only improve their product quality and operational efficiency but also contribute to a more sustainable and innovative food industry. The future of fruit drying is bright, and it's clear that China's contributions to this field will continue to shape the industry for years to come.

Frequently Asked Questions

1. What are the main advantages of using a modern fruit dryer machine?

Answer: Modern fruit dryer machines offer several key advantages, including improved energy efficiency, precise temperature and humidity control, increased capacity for large-scale production, versatility in handling different types of fruits, and the ability to preserve nutritional content and flavor profiles of dried fruits.

2. How do automatic fruit dehydration technologies improve the drying process?

Answer: Automatic fruit dehydration technologies enhance the drying process by minimizing human intervention, ensuring consistent quality across batches, reducing the risk of contamination, and streamlining the entire production process from fruit preparation to packaging.

3. What factors should be considered when choosing a fruit dryer machine for commercial use?

Answer: When selecting a fruit dryer machine for commercial use, important factors to consider include capacity requirements, energy efficiency ratings, versatility and adaptability to different fruit types, automation features, quality control mechanisms, and the availability of maintenance and support services from the manufacturer.

4. How are smart sensors and IoT integration improving fruit drying technology?

Answer: Smart sensors and IoT integration enhance fruit drying technology by enabling real-time monitoring and control of various parameters such as temperature, humidity, and air flow. This data-driven approach allows for optimization of the drying process, ensuring the best possible results while minimizing energy consumption.

5. What are some emerging trends in fruit drying technology?

Answer: Emerging trends in fruit drying technology include the integration of artificial intelligence and machine learning for process optimization, the development of more sustainable and eco-friendly drying solutions, the exploration of nanotechnology for enhanced preservation, and the creation of hybrid drying systems that combine multiple drying methods for superior results.