Why Dryera heat pump drying machine? |

|  |

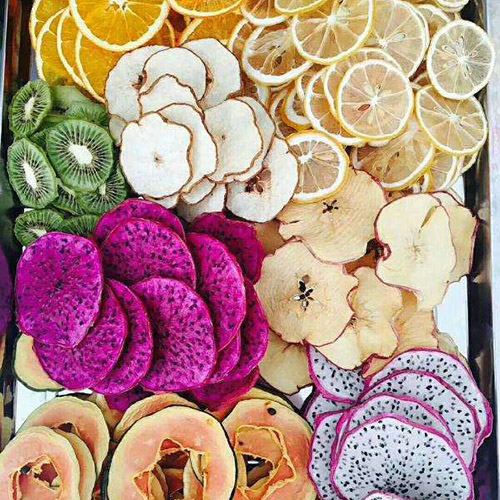

This dehydrator machine mainly for the big capacity, from 1000kg to 5000kg optional.

This type the dryer machine and drying room are separated, inside of the room with trolleys and trays. The room size can customized, quantity of trays and trolleys are also can be varied depend on different types of products drying.

This one is very easy to install, because the dryer machine already with big fans, which means no need extra fans in the chamber, just connect the dyer machine part and the room part is ok. Also it saves the size of the drying room and saves labour for the installation too.

| Model |

| DTR-15 | DTR-25 |

| Temp. Control | ℃ | 18~75 | 18~75 |

| Dehumi. Capacity | L/h | 45 | 65 |

| Functions |

| Heat dry, Cool dry, Dehumidify | Heat dry, Cool dry, Dehumidify |

| Trays Quantites | PCS | 324-540 | 432-720 |

| Trays Size | mm | 800*600 | 800*600 |

| Performance |

|

|

|

| Rated Power Input | kW | 17.6 | 26.4 |

| Rated Current Input | A | 35 | 44.6 |

| Voltage/Frequency | V,HZ | 380V/50HZ/60Hz | 380V/50HZ/60Hz |

| Emergency Auxiliary Heating Power Input | kW | 18 | 18 |

| Refrigerant Type |

| R134a | R134a |

| Weight and packing |

|

|

|

| Operation ambient Temp. | ℃ | -5-50 | -5-50 |

| Weight | kg | 850 | 1150 |

| Machine Dimension(L*W*H) | mm | 1310*2200*2650 | 1600*2200*2650 |

| Drying Chamber Size | mm | 5000*2800*2750 | 6500*2800*2750 |

Why heat pump dehydrator? |

The new heat pump technology used in the drying industry is a major breakthrough, which saves the operation cost up to 75%. The difference similar as the traditional electric water heater and the heat pump water heater, because heat pump is to transfer the heat in the air from outside to the chamber inside.

Bellowing is the electricity consumption in different dryers:

| Heating method | Electric heater | Coal boiler | Coal-fired boiler | Natural gas boiler | Nomal HPD | Our HPD |

| Calories required to remove 1kg of water | According to relevant authoritative information, the average heat required to remove 1kg of water is 1.35kw/kg, or 1161kcal/kg |

| Fuel type | Electricity | Coal | Diesel fuel | Natural gas | Electricity | Electricity |

| Burning value | 860kcal/kwh | 5500kcal/kg | 8000kcal/L | 8600kcal/m3 | 860kcal/kwh | 860kcal/kwh |

| Thermal efficiency | 95% | 30% | 85% | 85% | 300% | 500% |

| Effective calorific value | 817kcal | 1650kcal | 6800kcal | 7310kcal | 2580kcal | 4300kcal |

| unit price of fuel | 0.6yuan/kwh | 1yuan/kg | 7.4yuan/L | 5yuan/m3 | 0.6yuan/kwh | 0.6yuan/kwh |

| consume fuel | 0.852kwh | 0.7kg | 0.17L | 0.159m3 | 0.27kwh | 0.162kwh |

| running cost | 0.852 | 0.7 | 1.26 | 0.795 | 0.27 | 0.162 |

| labor cost | Meddium | High | High | High | Meddium | Low |

| Safety performance | Not safe | Not safe | Not safe | Not safe | Not safe | Safe |

| Environmental pollution | No | very serious | quite serious | quite serious | No | No |

| Equipment service life | 5-8 years | 6-9years | 6-9years | 6-9years | 6-10years | 10-15years |

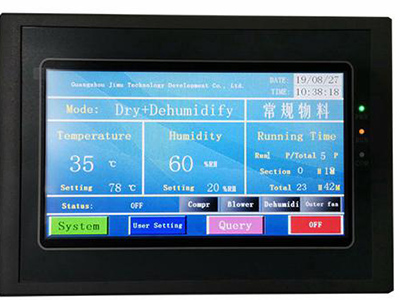

Digital PLC control board easy to set your parameters like drying temperature, humidity and drying time etc.

Smart module control system, automatic regulation and a 24 - hour unattended operation.

Inside of the drying room optional with SS304 or coated steel The trolleys and trays are with food grade SS304 material Quantity of trolleys and trays can be customized |

Patented negative pressure fan design, the products can be dried 100% evenly |  International top compress brand Copeland from Emerson company |

No need tools to open the panel and check each parts if need any inspect or repair |

Hot tags: fruit dryer machine, dry machine for food, cabinet dryer food, large dehydrator, industrial air dryer, agriculture dryer, air dryer machine, electric drying oven, industrial dehydrator machine big, food drier dehydrator, China, wholesale, manufacturers, suppliers, factory, price, manufacturing company

meat drying

meat drying seafood dehydrating

seafood dehydrating pet food dehydrating

pet food dehydrating green leaves dehydrating

green leaves dehydrating fish dehydrating

fish dehydrating shrimp dehydrating

shrimp dehydrating beef jerky drying

beef jerky drying Other products dehydrating

Other products dehydrating