Content Menu

● Understanding Food Dehydration

● Types of Food Dryers

● How Do They Work?

>> Condenser Dryers

>> Heat Pump Dryers

● Energy Efficiency Comparison

● Advantages of Each Type

>> Advantages of Condenser Dryers

>> Advantages of Heat Pump Dryers

● Choosing the Right Dryer for Your Needs

● Factors Influencing Dryer Performance

● Maintenance Considerations

● Environmental Impact

● Innovations in Dryer Technology

● Conclusion

● FAQ

>> 1. What is the main difference between condenser and heat pump dryers?

>> 2. Which type of dryer is better for preserving nutrients in food?

>> 3. Are heat pump dryers more expensive than condenser dryers?

>> 4. How does humidity affect the performance of these dryers?

>> 5. Can both types of dryers be used for all kinds of foods?

● Citations:

In the realm of food processing, particularly in the production of dried foods, the efficiency and effectiveness of drying equipment play a crucial role. This article explores the differences between two popular types of dryers used in food dehydration: condenser dryers and heat pump dryers. We will delve into their energy-saving capabilities, operational efficiencies, and overall effectiveness in food drying processes.

Understanding Food Dehydration

Food dehydration is a method of preserving food by removing moisture content, which inhibits the growth of bacteria, yeast, and mold. This process not only extends the shelf life of food but also enhances flavors and nutrients. The choice of drying technology significantly impacts the quality and efficiency of this process.

Types of Food Dryers

Before comparing condenser and heat pump dryers, it's essential to understand the different types of food dehydrators available in the market:

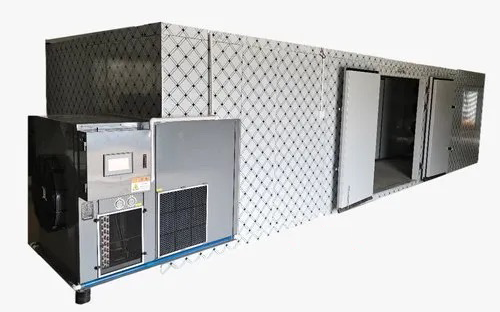

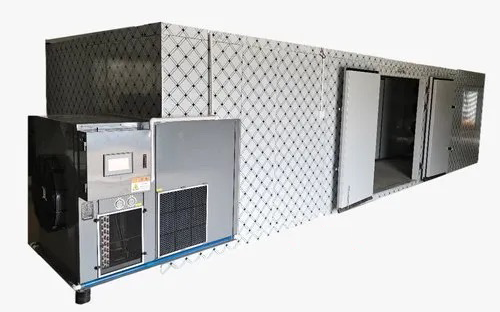

- Condenser Dryers: These dryers operate by heating air to high temperatures and circulating it through the food. The moisture is then condensed into water, which is collected in a tray.

- Heat Pump Dryers: These utilize a closed-loop system to recycle hot air. They operate at lower temperatures compared to condenser dryers, making them more energy-efficient.

How Do They Work?

Condenser Dryers

Condenser dryers work by:

- Heating air using electrical elements.

- Circulating this hot air through the drying chamber.

- Collecting moisture in a condensation tray.

This method allows for rapid drying but can consume significant amounts of energy due to the high temperatures involved.

Heat Pump Dryers

Heat pump dryers function differently:

- They use a refrigerant cycle to absorb heat from the environment.

- The heat is then used to warm up air that is circulated through the food.

- Moisture is extracted at lower temperatures (around 50°C), which helps preserve more nutrients.

This technology allows heat pump dryers to use up to 50% less energy than traditional condenser dryers while providing gentle drying conditions that protect food quality.

Energy Efficiency Comparison

| Feature | Condenser Dryer | Heat Pump Dryer |

| Energy Consumption | High (uses more electricity) | Low (up to 50% less than condenser) |

| Operating Temperature | High (70-75°C) | Low (around 50°C) |

| Drying Time | Faster drying cycles | Longer drying cycles |

| Initial Cost | Generally lower | Higher initial investment |

| Long-term Savings | Higher operational costs | Significant savings over time |

Advantages of Each Type

Advantages of Condenser Dryers

- Faster Drying: They can dry products quickly due to higher operating temperatures.

- Lower Initial Cost: Typically, they are less expensive upfront compared to heat pump models.

Advantages of Heat Pump Dryers

- Energy Efficiency: Lower energy consumption translates to reduced operational costs over time.

- Gentle on Food: The lower temperatures help retain nutrients and flavors better than higher-temperature methods.

- Versatility: Suitable for a wide range of products including fruits, vegetables, and meats without compromising quality.

Choosing the Right Dryer for Your Needs

When selecting between a condenser dryer and a heat pump dryer for food dehydration, consider the following factors:

- Volume of Production: For large-scale operations requiring quick turnaround times, condenser dryers may be beneficial despite higher energy costs.

- Quality Concerns: If preserving flavor and nutrients is paramount, heat pump dryers are preferable due to their gentle drying process.

- Budget Constraints: Evaluate both initial costs and long-term savings on energy bills when making a decision.

Factors Influencing Dryer Performance

Several factors can influence the performance of both condenser and heat pump dryers:

1. Humidity Levels: High humidity can affect drying efficiency. Heat pump dryers tend to perform better in humid conditions due to their ability to recycle air effectively.

2. Type of Food: Different foods require different drying conditions. For instance, fruits may need lower temperatures for optimal drying while meats might require higher temperatures.

3. Airflow: Adequate airflow is essential for effective drying. Both types of dryers must ensure proper circulation for uniform drying results.

4. Load Size: Overloading a dryer can lead to uneven drying. It's crucial to adhere to manufacturer guidelines regarding load sizes for optimal performance.

5. Pre-treatment Processes: Some foods benefit from pre-treatment methods such as blanching or soaking before dehydration, which can enhance the final product's quality.

Maintenance Considerations

Regular maintenance is vital for ensuring optimal performance and longevity of both condenser and heat pump dryers:

- Cleaning Filters: Clogged filters can reduce airflow and efficiency. Regularly check and clean filters according to manufacturer recommendations.

- Inspecting Seals: Ensure that door seals are intact to prevent heat loss in both types of dryers.

- Monitoring Temperature Settings: Regularly check temperature settings to ensure they align with recommended levels for specific foods.

- Professional Servicing: Consider scheduling professional maintenance checks annually to address any potential issues before they become significant problems.

Environmental Impact

As sustainability becomes increasingly important in food production, the environmental impact of drying technologies cannot be overlooked:

- Energy Consumption: Heat pump dryers' lower energy consumption contributes positively towards reducing carbon footprints in food processing operations.

- Waste Management: Both types of dryers generate waste products such as condensed water; however, heat pump systems often have mechanisms for reusing this water in other processes or minimizing waste output.

Innovations in Dryer Technology

The field of food dehydration technology continues to evolve with innovations aimed at improving efficiency and product quality:

1. Smart Technology Integration: Modern dryers may include smart technology that allows operators to monitor performance remotely, adjust settings automatically based on humidity levels, and receive alerts for maintenance needs.

2. Hybrid Systems: Some manufacturers are developing hybrid systems that combine features from both condenser and heat pump technologies, offering flexibility in operation while maximizing energy savings.

3. Advanced Materials: New materials are being explored for dryer construction that enhance insulation properties, further improving energy efficiency by reducing heat loss during operation.

4. Automation Features: Automation in loading/unloading processes can streamline operations, reduce labor costs, and enhance overall productivity in large-scale facilities.

5. Research on Food Quality Preservation: Ongoing research focuses on optimizing drying parameters specific to various foods to maximize nutrient retention while minimizing drying time.

Conclusion

Both condenser and heat pump dryers have their merits in food dehydration processes. While condenser dryers offer faster drying times at a lower initial cost, heat pump dryers provide significant energy savings and better preservation of food quality over time. Ultimately, the choice between these two types should align with your specific production needs, budget considerations, and quality requirements.

Investing in the right type of dryer can lead not only to enhanced product quality but also improved operational efficiency and sustainability within your food processing business. As technology advances, staying informed about new developments will further empower producers to make choices that benefit both their bottom line and environmental impact.

FAQ

1. What is the main difference between condenser and heat pump dryers?

The main difference lies in their operation; condenser dryers use high temperatures for rapid drying while heat pump dryers operate at lower temperatures using recycled hot air for energy efficiency.

2. Which type of dryer is better for preserving nutrients in food?

Heat pump dryers are better for preserving nutrients as they operate at lower temperatures compared to condenser dryers.

3. Are heat pump dryers more expensive than condenser dryers?

Yes, heat pump dryers typically have a higher initial cost but offer significant savings on energy bills in the long run.

4. How does humidity affect the performance of these dryers?

High humidity can prolong drying times for both types; however, heat pump dryers are generally more effective in maintaining consistent performance under varying humidity levels due to their closed-loop system.

5. Can both types of dryers be used for all kinds of foods?

Yes, both condenser and heat pump dryers can be used for various foods including fruits, vegetables, meats, and herbs; however, heat pump dryers are often preferred for delicate items due to their gentle drying process.

Citations:

[1] https://aradmachineryco.com/article/Food-dehydrator-buying-guide

[2] https://www.siemens-home.bsh-group.com.hk/en/appliances/laundrycare/tumble-dryers/comparison-heat-pump-dryer-condenser-dryer

[3] https://www.made-in-china.com/manufacturers/top-food-dehydrators.html

[4] https://www.alamy.com/stock-photo/food-dehydrator.html

[5] https://www.ike.cn/video.html

[6] https://www.youtube.com/watch?v=hsDU-kH01cs

[7] https://aradmachineryco.com/article/How-to-use-a-dehydratormachine

[8] https://www.bosch-home.com.my/experience-bosch/living-with-bosch/fresh-reads/6-reasons-why-you-need-a-bosch-heat-pump-dryer-in-your-life

[9] https://www.dreamstime.com/photos-images/food-dehydrator.html

[10] https://www.youtube.com/watch?v=1fP2rSLjys4

[11] https://www.youtube.com/watch?v=61kmLsq51VU

[12] https://www.webstaurantstore.com/guide/741/food-dehydrators-buying-guide.html