Content Menu

● Introduction

● Understanding Food Drying

● Types of Food Drying Technologies

>> Heat Pump Drying Technology

● Advantages of Heat Pump Dryers

>> Versatility of Heat Pump Dryers

● Applications of Food Drying

>> Preservation of Meats

● Challenges in Food Drying

>> Technological Innovations

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between heat pump dryers and traditional dryers?

>> 2. How does food drying affect nutritional value?

>> 3. What types of foods can be dried using heat pump technology?

>> 4. Are heat pump dryers environmentally friendly?

>> 5. What are the cost implications of using heat pump dryers?

Introduction

Food drying is a crucial process in the preservation of food, extending its shelf life and maintaining its nutritional value. As a method that has been utilized for centuries, drying removes moisture from food, inhibiting the growth of bacteria, yeasts, and molds. In recent years, heat pump dryers have emerged as a revolutionary technology in the food drying industry, offering energy-efficient and effective solutions for food manufacturers. This article explores the various aspects of food drying technology, focusing on the advantages and applications of heat pump dryers.

Understanding Food Drying

Food drying is defined as the process of removing moisture from food to prevent spoilage. Historically, methods such as sun drying and air drying were common, but these techniques often resulted in inconsistent quality and longer drying times. The primary goal of food drying is to reduce the water content to a level that inhibits microbial growth, thus preserving the food for extended periods.

Types of Food Drying Technologies

The landscape of food drying has evolved significantly, with various technologies now available. Traditional methods, while still in use, have limitations in terms of efficiency and quality. Modern methods such as freeze drying and spray drying have gained popularity due to their ability to preserve the integrity of the food.

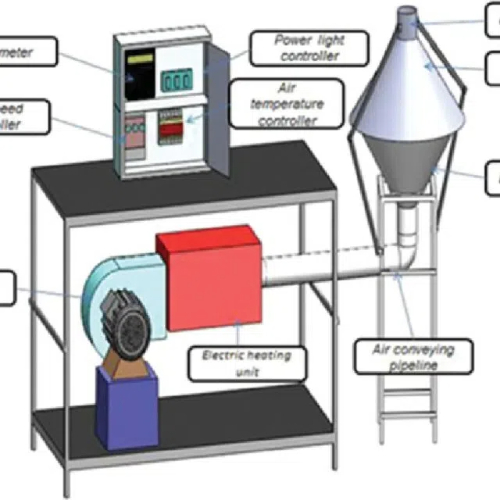

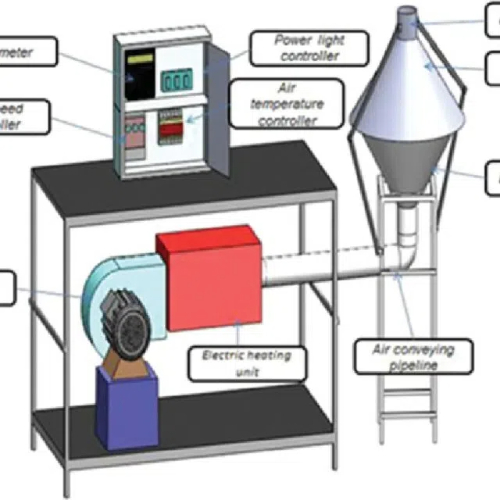

Heat Pump Drying Technology

Heat pump drying technology represents a significant advancement in this field. This method utilizes a closed-loop system that recycles heat, making it highly energy-efficient. The process involves drawing in ambient air, heating it, and then circulating it through the food product. The moisture is then condensed and removed, resulting in high-quality dried food.

Advantages of Heat Pump Dryers

Heat pump dryers offer numerous advantages over traditional drying methods. One of the most significant benefits is their energy efficiency. These dryers can consume up to 50% less energy than conventional electric dryers, leading to substantial savings on utility bills. Additionally, heat pump dryers operate at lower temperatures, which helps preserve the nutritional value and flavor of the food.

Versatility of Heat Pump Dryers

Another advantage is their versatility. Heat pump dryers can be used to dry a wide range of food products, from fruits and vegetables to meats and herbs. This flexibility makes them an ideal choice for food manufacturers looking to diversify their product offerings.

Applications of Food Drying

The applications of food drying are vast and varied. In the snack food industry, dried fruits and vegetables are increasingly popular due to their convenience and health benefits. Heat pump dryers are particularly effective in producing high-quality dried snacks that retain their color, flavor, and nutritional content.

Preservation of Meats

In addition to snacks, food drying plays a crucial role in the preservation of meats. Jerky, for example, is made by removing moisture from meat, which not only extends its shelf life but also enhances its flavor. The pharmaceutical and herbal industries also benefit from food drying technology, as it allows for the preservation of active compounds in herbs and medicinal plants.

Challenges in Food Drying

Despite the advancements in food drying technology, challenges remain. Quality control is a significant concern, as inconsistent drying can lead to variations in product quality. Additionally, while heat pump dryers are more energy-efficient, they still require a substantial amount of energy, raising questions about their environmental impact.

Technological Innovations

Technological advancements continue to address these challenges, with innovations aimed at improving efficiency and product quality. The integration of automation and smart technology is also on the rise, allowing for better monitoring and control of the drying process.

Future Trends in Food Drying Technology

The future of food drying technology looks promising, with ongoing research and development focused on sustainability and efficiency. Emerging trends include the use of renewable energy sources to power drying systems and the development of more sophisticated drying technologies that minimize energy consumption while maximizing product quality.

Conclusion

Food drying technology has come a long way from its traditional roots, evolving into a sophisticated industry that prioritizes efficiency and quality. Heat pump dryers represent a significant advancement, providing energy-efficient solutions that preserve the nutritional value of food. As the industry continues to innovate, the future of food drying looks bright, with the potential for even greater advancements in technology and sustainability.

Frequently Asked Questions

1. What is the difference between heat pump dryers and traditional dryers?

Heat pump dryers recycle heat, making them more energy-efficient compared to traditional dryers that vent hot air outside.

2. How does food drying affect nutritional value?

Proper drying techniques can preserve nutrients, but excessive heat can lead to nutrient loss.

3. What types of foods can be dried using heat pump technology?

A wide variety of foods, including fruits, vegetables, and meats, can be effectively dried using heat pump technology.

4. Are heat pump dryers environmentally friendly?

Yes, they consume less energy and reduce greenhouse gas emissions compared to conventional dryers.

5. What are the cost implications of using heat pump dryers?

While the initial investment may be higher, the long-term savings on energy bills can offset the costs.