Content Menu

● Introduction

● Understanding Food Drying Technologies

>> Heat Pump Dryers

>> Gas Dryers

● Cost-Effectiveness Over Time

>> 1. Initial Investment

>> 2. Energy Consumption

>> 3. Maintenance Costs

>> 4. Longevity and Durability

● Performance Comparison: Heat Pump vs Gas Dryer

>> Drying Efficiency

>> Environmental Impact

● Innovations in Heat Pump Technology

● Challenges and Considerations

● Conclusion

● Related Questions

>> 1. What are the main advantages of using a heat pump dryer for food drying?

>> 2. How does the drying time compare between heat pump and gas dryers?

>> 3. Are there specific foods that benefit more from heat pump drying?

>> 4. What factors should I consider when choosing between a heat pump dryer and a gas dryer?

>> 5. Can I use a heat pump dryer for large-scale food processing?

Introduction

In the world of food preservation, drying is a critical process that extends shelf life and maintains quality. As a manufacturer of food drying machines, we understand the importance of choosing the right technology for optimal results. This article will explore the comparison between heat pump dryers and gas dryers, focusing on their cost-effectiveness over time, energy efficiency, and overall performance in food drying applications.

Understanding Food Drying Technologies

Food drying is a method used to remove moisture from food products to prevent spoilage. There are various technologies available, but two of the most common types are heat pump dryers and gas dryers.

Heat Pump Dryers

Heat pump dryers utilize a refrigeration cycle to extract moisture from food. They work by circulating air through the drying chamber, where heat is absorbed from the environment and transferred to the food. This method is known for its energy efficiency and ability to operate at lower temperatures, preserving the nutritional value of the food.

Heat pump dryers operate by recycling hot air. The process begins with ambient air being drawn into the dryer. This air is then heated and circulated through the food items. As it absorbs moisture from the food, it cools down, causing the moisture to condense. This condensed moisture is collected, and the now-dry air is reheated and cycled back through the drying chamber. This closed-loop system allows for continuous moisture removal while minimizing energy loss.

Gas Dryers

Gas dryers, on the other hand, use combustion to generate heat. They typically operate at higher temperatures and can dry food more quickly than heat pump dryers. However, this method may lead to a loss of nutrients and flavor due to the intense heat.

Advantages of Gas Dryers

- Speed: Gas dryers excel at reaching high temperatures quickly, making them ideal for time-sensitive situations when rapid drying is necessary.

- Cost: The initial investment for gas dryers can be lower compared to heat pump dryers, especially if a gas line is already available.

Cost-Effectiveness Over Time

When considering whether heat pump dryers or gas dryers are more cost-effective over time, several factors come into play:

1. Initial Investment

Heat pump dryers tend to have a higher initial purchase price compared to gas dryers. However, this upfront cost can be offset by lower operating costs over time.

2. Energy Consumption

Heat pump dryers are known for their energy efficiency. They consume significantly less energy than gas dryers because they recycle heat rather than generating it from scratch. This can lead to substantial savings on energy bills.

Energy Efficiency Comparison

- Heat Pump Dryers: Approximately 28% more efficient than traditional gas or electric models.

- Gas Dryers: While they may have lower operational costs per load due to cheaper fuel prices, they generally consume more energy overall due to their higher operational temperatures.

3. Maintenance Costs

Gas dryers require regular maintenance due to their combustion systems, which can add to long-term costs. In contrast, heat pump dryers generally have lower maintenance requirements, resulting in further savings.

4. Longevity and Durability

Heat pump dryers often have a longer lifespan compared to gas dryers due to their less aggressive drying process. This durability can translate into fewer replacements and repairs over time.

Performance Comparison: Heat Pump vs Gas Dryer

Drying Efficiency

While gas dryers can dry food quickly due to higher temperatures, heat pump dryers excel in preserving the quality of dried products. The lower drying temperatures help maintain flavor, color, and nutritional value.

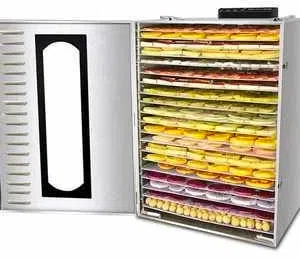

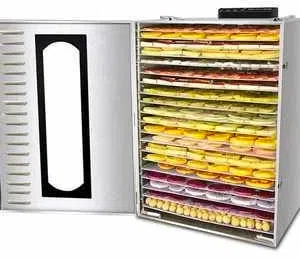

Visual Comparison of Drying Processes

Environmental Impact

Heat pump dryers are more environmentally friendly compared to gas dryers. They produce fewer greenhouse gas emissions due to their energy-efficient operation and reliance on electricity rather than fossil fuels.

Innovations in Heat Pump Technology

The food drying industry is witnessing rapid advancements with heat pump technology at the forefront. Innovations such as automation and smart technology integration are enhancing the efficiency and effectiveness of drying processes.

Smart Technology Integration

Modern heat pump systems can now incorporate sensors that monitor moisture levels in real-time. This allows for precise control over the drying process, ensuring optimal results without wasting energy or compromising product quality.

Challenges and Considerations

Despite their advantages, there are some challenges associated with adopting heat pump technology:

- Initial Costs: The upfront investment for heat pump systems can be significant compared to traditional methods.

- Training Needs: Operators may require training to effectively manage new technologies.

- Longer Drying Times: Heat pump systems typically take longer to dry products compared to gas systems due to lower operating temperatures.

Conclusion

In conclusion, while gas dryers may offer faster drying times, heat pump dryers prove to be more cost-effective over time when considering energy consumption, maintenance costs, and product quality. For businesses looking for long-term solutions in food preservation, investing in heat pump technology is a wise choice that balances efficiency with sustainability.

Related Questions

1. What are the main advantages of using a heat pump dryer for food drying?

Heat pump dryers offer energy efficiency, lower operating costs, and better preservation of food quality compared to traditional gas dryers.

2. How does the drying time compare between heat pump and gas dryers?

Gas dryers typically dry food faster due to higher temperatures; however, this can compromise the quality of the dried product.

3. Are there specific foods that benefit more from heat pump drying?

Yes, delicate foods such as fruits and herbs benefit greatly from heat pump drying as it preserves their flavor and nutrients better than higher temperature methods.

4. What factors should I consider when choosing between a heat pump dryer and a gas dryer?

Consider initial investment costs, energy consumption rates, maintenance needs, desired product quality, and environmental impact when making your choice.

5. Can I use a heat pump dryer for large-scale food processing?

Absolutely! Heat pump dryers are suitable for both small-scale and large-scale food processing operations due to their efficiency and scalability.

By understanding these aspects of heat pump vs gas dryer technologies in food drying applications, businesses can make informed decisions that enhance productivity while ensuring quality preservation of their products.