Content Menu

● Understanding Food Drying Technologies

● Heat Pump Dryers vs. Vented Dryers

● Advantages of Heat Pump Dryers

● Considerations for Using Heat Pump Dryers

● Applications of Heat Pump Dryers in Food Processing

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What types of foods can be dried using heat pump dryers?

>> 2. How does the energy consumption of heat pump dryers compare with vented dryers?

>> 3. Can I use a heat pump dryer indoors?

>> 4. What maintenance do heat pump dryers require?

>> 5. Are there any downsides to using heat pump dryers?

The efficiency of food drying is a critical aspect of food preservation and preparation, particularly in the context of modern food processing. As the demand for dried foods increases globally, manufacturers and consumers alike are exploring the best technologies available for drying food products. Among these technologies, heat pump dryers have emerged as a highly efficient option compared to traditional vented dryers. This article will delve into the differences between heat pump dryers and vented dryers, focusing on their efficiency, operational mechanisms, and suitability for food drying applications.

Understanding Food Drying Technologies

What is Food Drying?

Food drying is a dehydration process that removes moisture from food to prevent spoilage. This method extends the shelf life of various products, including fruits, vegetables, meats, and herbs. The primary goal of drying is to inhibit the growth of bacteria, yeast, and molds that thrive in moist environments.

There are several methods for drying food, including:

- Sun Drying: Utilizing direct sunlight to dehydrate foods. This method is weather-dependent and not suitable for all climates.

- Air Drying: Involves hanging foods in a well-ventilated area. This method is often used for herbs and certain vegetables.

- Oven Drying: Uses an oven at low temperatures to dry foods. While convenient, this method can be energy-intensive and less effective than dedicated dehydrators.

- Electric Dehydrators: These appliances use electric heating elements and fans to circulate air around the food, promoting even drying.

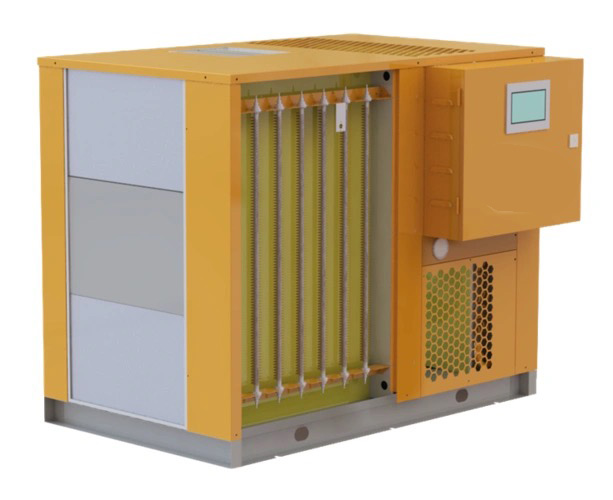

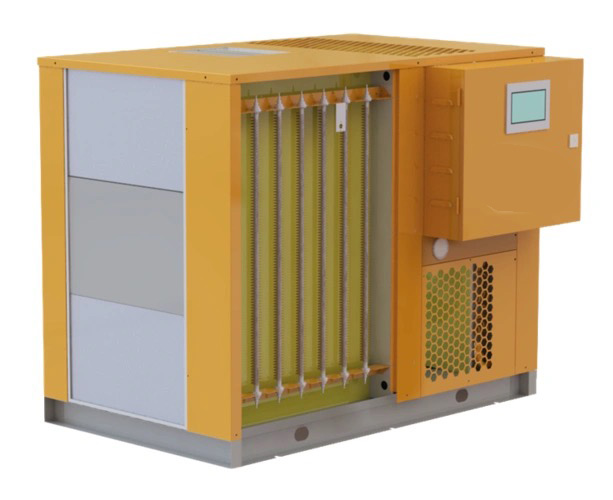

- Heat Pump Dryers: A newer technology that uses a closed-loop system to recycle hot air, making it more energy-efficient.

Heat Pump Dryers vs. Vented Dryers

To understand why heat pump dryers are often considered more efficient than vented dryers, it's essential to compare their operational mechanisms.

- Heat Pump Dryers: These dryers operate by drawing in air from the environment, heating it using a heat pump system, and circulating it through the drying chamber. The moisture-laden air is then cooled down in an evaporator, causing moisture to condense and be collected. The dry air is reheated and recirculated back into the chamber. This process allows for lower temperature drying while maintaining high energy efficiency.

- Vented Dryers: Traditional vented dryers work by heating air and blowing it into the drum where wet clothes or food items are placed. The moist air is then expelled outside through a vent. This method requires a significant amount of energy because it continuously heats new air while losing heated air outside.

| Feature | Heat Pump Dryer | Vented Dryer |

| Energy Efficiency | High (up to 68% less energy usage) | Lower (constant energy loss) |

| Temperature Control | Low temperatures reduce wear | High temperatures can damage items |

| Installation Flexibility | No vent required | Requires external venting |

| Moisture Management | Recycles moisture | Disposes of moisture externally |

Advantages of Heat Pump Dryers

1. Energy Efficiency: Heat pump dryers can significantly reduce energy consumption compared to vented dryers. They utilize a closed-loop system that recycles hot air rather than expelling it outside, making them ideal for both home use and commercial applications.

2. Gentler on Foods: The lower temperatures used in heat pump drying help preserve the nutritional quality of foods better than high-temperature methods. This is particularly important for delicate items like fruits and herbs.

3. Versatility: Heat pump dryers can be used in various settings without needing extensive modifications to facilities since they do not require external venting.

4. Cost Savings: Although heat pump dryers may have a higher initial purchase price, their energy efficiency leads to lower operational costs over time.

5. Environmental Impact: With growing concerns about energy consumption and sustainability, heat pump dryers offer a more eco-friendly solution by reducing overall energy usage and minimizing carbon footprints associated with food processing.

Considerations for Using Heat Pump Dryers

While heat pump dryers offer numerous advantages, there are some considerations to keep in mind:

- Initial Investment: The upfront cost of purchasing a heat pump dryer can be higher than that of traditional vented models. However, this cost can often be offset by long-term savings on energy bills.

- Drying Time: Heat pump dryers typically have longer drying cycles compared to vented dryers due to their lower operating temperatures. This can be an important factor for commercial operations that require quick turnaround times.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance, including cleaning filters and checking drainage systems. Proper care will extend the lifespan of the dryer and maintain its efficiency.

Applications of Heat Pump Dryers in Food Processing

Heat pump dryers are increasingly being adopted in various sectors of food processing due to their efficiency and effectiveness:

- Fruit Drying: Heat pump technology allows for gentle drying processes that maintain flavor and nutritional value while preventing browning reactions often caused by high temperatures.

- Vegetable Dehydration: Vegetables can be dried at lower temperatures without losing their color or texture, making them more appealing when rehydrated.

- Herb Preservation: The delicate nature of herbs makes them well-suited for heat pump drying, which helps retain essential oils and flavors better than conventional methods.

- Meat Drying: For jerky production or other dried meat products, heat pump dryers provide consistent temperatures that ensure safe dehydration without compromising quality.

Future Trends in Food Drying Technology

As technological advancements continue to shape the food processing industry, several trends are emerging in the realm of food drying:

1. Smart Technology Integration: The incorporation of smart technology into heat pump dryers allows for remote monitoring and control via smartphones or tablets, enhancing user convenience and operational efficiency.

2. Sustainability Focus: With increasing awareness around environmental issues, manufacturers are focusing on developing more sustainable drying solutions that minimize waste and energy consumption.

3. Research into New Materials: Ongoing research into advanced materials for dryer construction aims to improve insulation properties further, enhancing energy efficiency even more.

4. Customization Options: As demand grows for specific dried products, manufacturers are offering customizable solutions tailored to meet individual customer needs regarding capacity and functionality.

5. Enhanced Automation: Automation in food processing continues to rise; thus, integrating automated systems within heat pump dryers will streamline operations further while ensuring consistent product quality.

Conclusion

In conclusion, heat pump dryers represent a significant advancement in food drying technology compared to traditional vented dryers. Their energy efficiency, gentleness on food products, versatility, environmental benefits, and suitability across various applications make them an excellent choice for both commercial producers and home users looking to preserve food effectively.

As the demand for dried foods continues to grow globally, investing in modern drying technologies like heat pump dryers becomes increasingly important for manufacturers aiming for sustainability and quality preservation.

Frequently Asked Questions

1. What types of foods can be dried using heat pump dryers?

- Heat pump dryers are suitable for a wide range of foods including fruits, vegetables, meats, and herbs.

2. How does the energy consumption of heat pump dryers compare with vented dryers?

- Heat pump dryers use significantly less energy—often up to 68% less—compared to traditional vented dryers due to their recycling mechanism.

3. Can I use a heat pump dryer indoors?

- Yes! Unlike vented dryers that require external ventilation, heat pump dryers can operate effectively indoors without any modifications.

4. What maintenance do heat pump dryers require?

- Regular cleaning of filters and ensuring proper drainage are essential maintenance tasks for optimal performance.

5. Are there any downsides to using heat pump dryers?

- While they are energy-efficient and gentle on foods, they may have longer drying times and higher initial costs compared to traditional models.