Content Menu

● Understanding Heat Pump Dryers

>> How Heat Pump Dryers Work

● Benefits of Heat Pump Dryers for Food Processing

>> 1. Energy Efficiency

>> 2. Improved Product Quality

>> 3. Versatility

>> 4. Environmental Impact

>> 5. Cost Savings

● Applications of Heat Pump Dryers in Food Processing

>> 1. Fruit and Vegetable Drying

>> 2. Meat Drying

>> 3. Herbal and Spice Drying

>> 4. Snack Food Production

>> 5. Dairy Product Drying

● Considerations When Investing in Heat Pump Dryers

>> 1. Initial Cost

>> 2. Space Requirements

>> 3. Maintenance

>> 4. Training and Operation

>> 5. Regulatory Compliance

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer?

>> 2. Can heat pump dryers be used for all types of food?

>> 3. How do heat pump dryers compare to traditional dryers?

>> 4. What are the maintenance requirements for heat pump dryers?

>> 5. Is the initial investment in a heat pump dryer worth it?

In recent years, the demand for energy-efficient appliances has surged, particularly in the food processing industry. Among these appliances, heat pump dryers have gained significant attention for their ability to dry food products while minimizing energy consumption. This article explores the benefits of heat pump dryers, their operational mechanisms, and why they are a worthy investment for food manufacturers and processors.

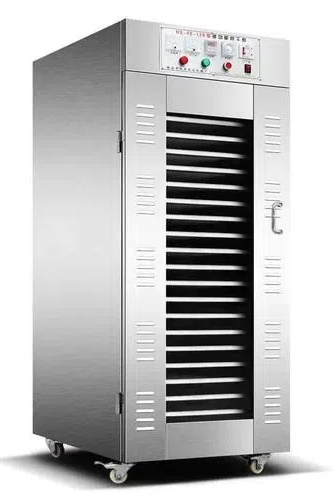

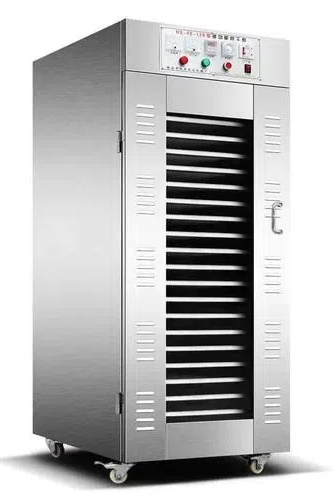

Understanding Heat Pump Dryers

Heat pump dryers are advanced drying systems that utilize a heat pump to transfer heat from the environment to the drying chamber. Unlike traditional dryers that expel hot air and moisture outside, heat pump dryers recycle the air within the system. This process not only conserves energy but also maintains a consistent temperature, which is crucial for drying sensitive food products.

How Heat Pump Dryers Work

The operation of a heat pump dryer can be broken down into several key steps:

1. Air Intake: The dryer draws in ambient air, which is then heated by the heat pump.

2. Drying Process: The heated air is circulated through the drying chamber, where it absorbs moisture from the food products.

3. Condensation: The moisture-laden air is then passed through a condenser, where the moisture is removed and collected as water.

4. Recycling Air: The now-dry air is reheated and recirculated back into the drying chamber, creating a closed-loop system.

This efficient process allows heat pump dryers to operate at lower temperatures compared to conventional dryers, making them ideal for drying delicate food items without compromising their quality.

Benefits of Heat Pump Dryers for Food Processing

1. Energy Efficiency

One of the most significant advantages of heat pump dryers is their energy efficiency. By recycling air and using lower drying temperatures, these dryers consume significantly less energy than traditional drying methods. This reduction in energy usage translates to lower operational costs, making heat pump dryers an attractive option for food manufacturers looking to improve their bottom line.

2. Improved Product Quality

Heat pump dryers provide a gentle drying process that helps preserve the nutritional value, flavor, and color of food products. The ability to control the drying temperature and humidity levels ensures that food items are dried evenly, reducing the risk of over-drying or burning. This is particularly important for high-value products such as fruits, vegetables, and herbs.

3. Versatility

Heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and herbs. Their adjustable settings allow manufacturers to customize the drying process based on the specific requirements of each product. This flexibility makes heat pump dryers suitable for various applications in the food processing industry.

4. Environmental Impact

As sustainability becomes a priority for many businesses, heat pump dryers offer an environmentally friendly solution. Their energy-efficient operation reduces greenhouse gas emissions, contributing to a smaller carbon footprint. Additionally, the closed-loop system minimizes waste by recycling air and water, further enhancing their eco-friendliness.

5. Cost Savings

While the initial investment in a heat pump dryer may be higher than that of traditional dryers, the long-term savings on energy costs and improved product quality can offset this expense. Many food manufacturers find that the return on investment (ROI) is realized within a few years due to reduced energy bills and increased product sales from higher quality offerings.

Applications of Heat Pump Dryers in Food Processing

Heat pump dryers are increasingly being adopted in various sectors of the food industry. Here are some common applications:

1. Fruit and Vegetable Drying

Heat pump dryers are ideal for drying fruits and vegetables, as they can maintain the integrity of the product while removing moisture. This method is particularly beneficial for producing dried fruits, vegetable chips, and herbs, which are popular in the health food market. The gentle drying process helps retain the vibrant colors and flavors of the produce, making them more appealing to consumers.

2. Meat Drying

In the production of jerky and other dried meat products, heat pump dryers provide a controlled environment that ensures safety and quality. The ability to maintain specific temperatures helps prevent the growth of harmful bacteria while achieving the desired texture and flavor. This is crucial for meat processors who need to comply with food safety regulations while delivering high-quality products.

3. Herbal and Spice Drying

Herbs and spices require careful drying to preserve their essential oils and flavors. Heat pump dryers offer the precision needed to dry these products without losing their aromatic properties, making them a preferred choice for herb and spice manufacturers. The ability to control humidity levels also ensures that the final product has a longer shelf life.

4. Snack Food Production

The snack food industry benefits from heat pump dryers by producing healthier options such as dried fruit snacks and vegetable crisps. The energy efficiency and product quality of heat pump dryers align well with the growing consumer demand for nutritious snack alternatives. Manufacturers can create innovative snack products that appeal to health-conscious consumers while maintaining profitability.

5. Dairy Product Drying

Heat pump dryers can also be used in the dairy industry for drying products like cheese and yogurt. The controlled drying process helps maintain the flavor and texture of dairy products, making them suitable for long-term storage and transportation. This application is particularly valuable for manufacturers looking to expand their product lines and reach new markets.

Considerations When Investing in Heat Pump Dryers

1. Initial Cost

While heat pump dryers offer numerous benefits, the initial investment can be a barrier for some businesses. It is essential to conduct a cost-benefit analysis to determine if the long-term savings justify the upfront expense. Businesses should consider factors such as energy savings, maintenance costs, and potential increases in product quality when evaluating the investment.

2. Space Requirements

Heat pump dryers may require more space than traditional dryers due to their design and the need for proper ventilation. Businesses should assess their available space and ensure that the installation of a heat pump dryer is feasible. Proper planning can help avoid disruptions during installation and ensure that the equipment operates efficiently.

3. Maintenance

Like any industrial equipment, heat pump dryers require regular maintenance to ensure optimal performance. Businesses should factor in maintenance costs and schedules when considering this investment. Regular cleaning of filters, checking for mechanical issues, and ensuring proper airflow are essential for maintaining the efficiency and longevity of the dryer.

4. Training and Operation

Investing in a heat pump dryer also means ensuring that staff are adequately trained to operate and maintain the equipment. Proper training can help prevent operational issues and ensure that the dryer is used to its full potential. Manufacturers should consider providing ongoing training and support to their employees to maximize the benefits of the new technology.

5. Regulatory Compliance

Food manufacturers must adhere to strict regulations regarding food safety and quality. When investing in heat pump dryers, it is crucial to ensure that the equipment meets all relevant industry standards and regulations. This may involve working with suppliers who can provide documentation and support for compliance efforts.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology, offering energy efficiency, improved product quality, and versatility. For food manufacturers and processors, the investment in heat pump dryers can lead to substantial cost savings and a positive environmental impact. As the demand for energy-efficient and high-quality food products continues to grow, heat pump dryers are poised to become a staple in the food processing industry.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer?

The main advantage is energy efficiency, as heat pump dryers recycle air and operate at lower temperatures, reducing energy consumption.

2. Can heat pump dryers be used for all types of food?

Yes, heat pump dryers are versatile and can be used for drying fruits, vegetables, meats, and herbs.

3. How do heat pump dryers compare to traditional dryers?

Heat pump dryers are more energy-efficient and provide better control over drying conditions, resulting in higher quality products.

4. What are the maintenance requirements for heat pump dryers?

Regular maintenance is needed to ensure optimal performance, including cleaning filters and checking for any mechanical issues.

5. Is the initial investment in a heat pump dryer worth it?

While the initial cost may be higher, the long-term savings on energy bills and improved product quality often justify the investment.