Content Menu

● Introduction

● What Are Heat Pump Tumble Dryers?

● Benefits of Using Heat Pump Dryers for Food

● Applications of Heat Pump Dryers in Food Industry

● How Heat Pump Dryers Work

● Choosing the Right Heat Pump Dryer for Your Needs

● Maintenance and Care for Heat Pump Dryers

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What types of food can be dried using heat pump dryers?

>> 2. Are heat pump dryers more energy-efficient than traditional dryers?

>> 3. How do heat pump dryers preserve the nutritional value of food?

>> 4. What maintenance is required for heat pump dryers?

>> 5. Can heat pump dryers be used for commercial food drying?

Introduction

Food drying is a crucial process in the food industry, allowing for the preservation of various products while maintaining their quality and nutritional value. As consumers increasingly seek healthier and more sustainable food options, the demand for efficient drying methods has grown. One such method is the use of heat pump tumble dryers, which offer a modern solution to traditional drying techniques. This article explores the benefits, applications, and technology behind heat pump dryers, particularly in the context of food drying.

What Are Heat Pump Tumble Dryers?

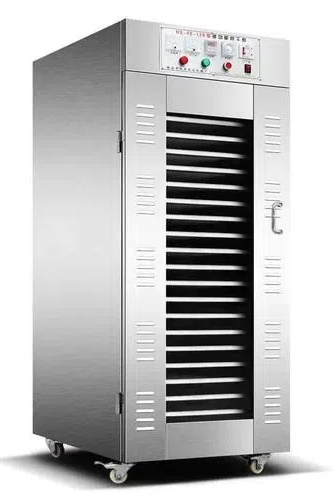

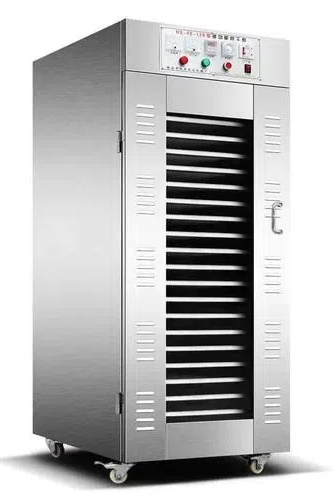

Heat pump tumble dryers utilize a closed-loop system that recycles hot air to dry food products. Unlike traditional dryers that expel hot air, heat pump dryers extract moisture from the food and return the warm air to the drying chamber. This process not only conserves energy but also allows for precise temperature control, making it ideal for sensitive food products.

Benefits of Using Heat Pump Dryers for Food

One of the primary advantages of heat pump dryers is their energy efficiency. They consume significantly less energy compared to conventional drying methods, leading to lower operational costs. Additionally, heat pump dryers excel in preserving the quality of food. The gentle drying process helps retain essential nutrients, flavors, and colors, ensuring that the final product is both appealing and nutritious. Safety is another critical aspect; heat pump dryers operate at lower temperatures, reducing the risk of food spoilage and contamination.

Applications of Heat Pump Dryers in Food Industry

Heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, herbs, and meats. For instance, companies have successfully implemented heat pump technology to dry apples, resulting in a product that retains its natural sweetness and texture. The adaptability of heat pump dryers makes them suitable for both small-scale operations and large commercial food processing facilities.

How Heat Pump Dryers Work

The drying process in heat pump dryers involves several stages. Initially, the dryer draws in air, which is then heated and circulated around the food. As the warm air passes over the food, it absorbs moisture, which is then extracted and condensed back into water. This cycle continues until the desired moisture content is achieved. The ability to control temperature and humidity levels is crucial, as it ensures that the food dries evenly without compromising its quality.

Choosing the Right Heat Pump Dryer for Your Needs

When selecting a heat pump dryer, several factors should be considered. These include the type of food being dried, the desired production capacity, and the specific features of the dryer. OEM services can provide customized solutions tailored to meet the unique needs of different businesses, ensuring optimal performance and efficiency.

Maintenance and Care for Heat Pump Dryers

To maintain the efficiency and safety of heat pump dryers, regular maintenance is essential. This includes cleaning filters, checking for leaks, and ensuring that the heating elements are functioning correctly. Addressing common issues, such as uneven drying or unusual noises, promptly can prevent more significant problems down the line.

Future Trends in Food Drying Technology

The food drying industry is evolving, with innovations in heat pump technology leading the way. Future trends include the integration of smart technology for better monitoring and control, as well as a focus on sustainability. As consumers become more environmentally conscious, the demand for energy-efficient and eco-friendly drying solutions will continue to rise.

Conclusion

Heat pump tumble dryers represent a significant advancement in food drying technology. Their energy efficiency, ability to preserve food quality, and safety make them an excellent choice for both small and large-scale food processing operations. As the industry continues to evolve, heat pump dryers will play a crucial role in meeting the growing demand for high-quality, sustainably dried food products.

Frequently Asked Questions

1. What types of food can be dried using heat pump dryers?

Heat pump dryers can effectively dry a variety of foods, including fruits, vegetables, herbs, and meats. Their gentle drying process helps retain the natural flavors and nutrients of the food.

2. Are heat pump dryers more energy-efficient than traditional dryers?

Yes, heat pump dryers are significantly more energy-efficient than traditional dryers. They recycle hot air, which reduces energy consumption and operational costs.

3. How do heat pump dryers preserve the nutritional value of food?

The low-temperature drying process used in heat pump dryers helps retain essential nutrients, flavors, and colors, ensuring that the final product is both nutritious and appealing.

4. What maintenance is required for heat pump dryers?

Regular maintenance includes cleaning filters, checking for leaks, and ensuring that heating elements are functioning correctly. Promptly addressing any issues can prevent more significant problems.

5. Can heat pump dryers be used for commercial food drying?

Absolutely! Heat pump dryers are suitable for both small-scale and large commercial food drying operations, providing efficient and high-quality drying solutions.