Content Menu

● Introduction

● Understanding Ventless Heat Pump Dryers

>> What is a Ventless Heat Pump Dryer?

>> How Do They Work?

● Energy Efficiency of Ventless Heat Pump Dryers

>> Energy Consumption

>> Cost Savings

>> Environmental Impact

● Applications in Food Drying

>> Food Drying Technology

>> Benefits of Using Heat Pump Technology for Food Drying

● Choosing the Right Food Drying Machine

>> Factors to Consider

● The Future of Food Drying Technology

>> Innovations in Heat Pump Technology

>> Integration with Smart Technology

>> Sustainability and Food Preservation

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a ventless heat pump dryer?

>> 2. Can ventless heat pump dryers be used for food drying?

>> 3. How do heat pump dryers compare to traditional dryers in terms of drying time?

>> 4. What types of food can be dried using heat pump technology?

>> 5. Are there any maintenance requirements for heat pump dryers?

Introduction

In recent years, the demand for energy-efficient appliances has surged, particularly in the realm of home laundry solutions. Among these, ventless heat pump dryers have gained significant attention for their innovative technology and energy-saving capabilities. However, as a manufacturer of food drying machines, we recognize the importance of understanding how these technologies can be applied beyond laundry, particularly in the food industry. This article will explore the efficiency of ventless heat pump dryers, their operational principles, and their potential applications in food drying.

Understanding Ventless Heat Pump Dryers

What is a Ventless Heat Pump Dryer?

A ventless heat pump dryer is a type of clothes dryer that uses a heat pump to dry clothes without the need for external venting. Unlike traditional dryers that expel hot air outside, ventless models recycle the air within the machine. This process not only conserves energy but also allows for installation in various locations without the need for ductwork.

How Do They Work?

Ventless heat pump dryers operate by using a closed-loop system. Here’s a simplified breakdown of the process:

1. Air Circulation: The dryer draws in air from the surrounding environment.

2. Heating: The air is heated using a heat pump, which is more energy-efficient than traditional heating elements.

3. Drying: The warm air is circulated through the wet clothes, absorbing moisture.

4. Condensation: The moisture-laden air is then passed through a condenser, where the water is extracted and collected, allowing the now-dry air to be reheated and recirculated.

This cycle continues until the clothes reach the desired dryness level.

Energy Efficiency of Ventless Heat Pump Dryers

Energy Consumption

One of the primary advantages of ventless heat pump dryers is their energy efficiency. They typically consume 50% less energy than traditional dryers. This is largely due to their ability to recycle heat and moisture, which minimizes the energy required to dry clothes.

Cost Savings

While the initial purchase price of a ventless heat pump dryer may be higher than that of a conventional dryer, the long-term savings on energy bills can offset this cost. Homeowners can expect to see a reduction in their electricity bills, making these dryers a cost-effective choice over time.

Environmental Impact

Using less energy not only saves money but also reduces the carbon footprint associated with laundry. For environmentally conscious consumers, ventless heat pump dryers represent a sustainable choice that aligns with green living principles.

Applications in Food Drying

Food Drying Technology

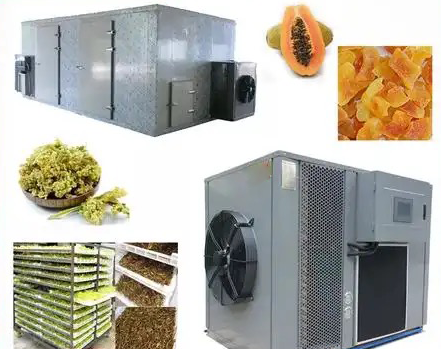

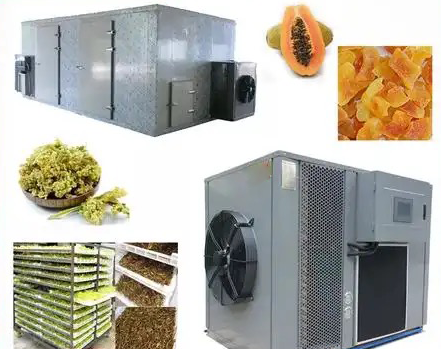

As a manufacturer of food drying machines, we understand that the principles of heat pump technology can be effectively applied to food drying processes. Food drying is a method of preserving food by removing moisture, which inhibits the growth of bacteria, yeast, and mold.

Benefits of Using Heat Pump Technology for Food Drying

1. Energy Efficiency: Similar to their application in laundry, heat pump technology in food dryers can significantly reduce energy consumption. This is particularly beneficial for large-scale food processing operations where energy costs can be substantial.

2. Temperature Control: Heat pump dryers allow for precise temperature control, which is crucial in food drying. Different foods require different drying temperatures to preserve flavor, color, and nutritional value.

3. Quality Preservation: The gentle drying process of heat pump technology helps maintain the quality of the food. Unlike traditional drying methods that can cause overheating, heat pump dryers ensure that food retains its essential nutrients and taste.

4. Versatility: Heat pump food dryers can be used for a variety of products, including fruits, vegetables, herbs, and meats. This versatility makes them an attractive option for food manufacturers and processors.

Choosing the Right Food Drying Machine

Factors to Consider

When selecting a food drying machine, several factors should be taken into account:

1. Capacity: Depending on the scale of production, choose a dryer that can handle the required volume of food.

2. Energy Efficiency Ratings: Look for machines with high energy efficiency ratings to ensure cost savings and environmental benefits.

3. Temperature Range: Ensure the dryer can accommodate the temperature requirements for the specific foods you plan to dry.

4. Ease of Use: Consider machines with user-friendly controls and features that simplify the drying process.

5. Maintenance Requirements: Opt for machines that are easy to clean and maintain to ensure longevity and consistent performance.

The Future of Food Drying Technology

Innovations in Heat Pump Technology

As technology continues to evolve, the food drying industry is witnessing significant innovations. New heat pump designs are being developed to enhance efficiency and reduce drying times. These advancements include improved heat exchangers and more sophisticated control systems that allow for better monitoring of drying conditions.

Integration with Smart Technology

The integration of smart technology into food drying machines is another exciting development. Smart dryers can be connected to the internet, allowing users to monitor and control the drying process remotely. This feature not only enhances convenience but also enables better energy management, as users can adjust settings based on real-time data.

Sustainability and Food Preservation

As consumers become more aware of sustainability issues, the demand for eco-friendly food processing solutions is on the rise. Heat pump technology aligns perfectly with this trend, offering a method of food preservation that minimizes energy use while maximizing quality. Manufacturers that adopt these technologies will likely find a competitive edge in the market.

Conclusion

Ventless heat pump dryers represent a significant advancement in energy-efficient technology, not only for laundry but also for food drying applications. Their ability to conserve energy, reduce costs, and maintain food quality makes them an excellent choice for manufacturers and processors in the food industry. As we continue to innovate and improve our food drying machines, we remain committed to providing our clients with the best solutions for their drying needs.

Frequently Asked Questions

1. What is the main advantage of using a ventless heat pump dryer?

The main advantage is energy efficiency, as they use significantly less energy compared to traditional dryers.

2. Can ventless heat pump dryers be used for food drying?

Yes, the technology can be effectively applied to food drying, offering benefits such as energy savings and quality preservation.

3. How do heat pump dryers compare to traditional dryers in terms of drying time?

Heat pump dryers may take longer to dry clothes or food, but they do so at lower temperatures, which can be beneficial for preserving quality.

4. What types of food can be dried using heat pump technology?

Heat pump dryers can be used for a variety of foods, including fruits, vegetables, herbs, and meats.

5. Are there any maintenance requirements for heat pump dryers?

Regular cleaning of filters and ensuring proper airflow are essential for maintaining the efficiency and longevity of heat pump dryers.