Content Menu

● Introduction

● Understanding Heat Pump Dryers

>> How Heat Pump Dryers Work

● Advantages of Using Heat Pump Dryers for Food Drying

>> 1. Energy Efficiency

>> 2. Preservation of Nutritional Value

>> 3. Improved Quality of Dried Products

>> 4. Versatility

>> 5. Reduced Drying Times

● Optimizing Drying Times with Heat Pump Technology

>> 1. Pre-Treatment of Food

>> 2. Proper Loading Techniques

>> 3. Monitoring Humidity Levels

>> 4. Regular Maintenance

>> 5. Utilizing Advanced Controls

● Case Studies: Successful Applications of Heat Pump Dryers

>> Case Study 1: Fruit Drying

>> Case Study 2: Vegetable Drying

>> Case Study 3: Herb Drying

● The Future of Food Drying Technology

>> Innovations in Heat Pump Technology

>> Market Trends

● Conclusion

● Frequently Asked Questions

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer differ from traditional dryers?

>> 3. Can heat pump dryers be used for all types of food?

>> 4. How can I reduce drying times with a heat pump dryer?

>> 5. What are the benefits of using heat pump dryers for food processing?

Introduction

In the world of food processing, drying is a crucial step that significantly affects the quality, shelf life, and flavor of food products. As a leading manufacturer of food drying machines in China, we specialize in providing OEM services to international brands, wholesalers, and producers. This article explores the capabilities of heat pump dryers in reducing drying times, their advantages, and how they can be optimized for food drying applications.

Understanding Heat Pump Dryers

Heat pump dryers are innovative appliances that utilize a heat pump system to dry food products efficiently. Unlike traditional dryers that expel hot air, heat pump dryers recycle the air within the system, making them more energy-efficient and environmentally friendly. This technology is particularly beneficial for food drying, as it allows for lower drying temperatures, preserving the nutritional value and flavor of the food.

How Heat Pump Dryers Work

Heat pump dryers operate on a simple principle: they extract moisture from the food by circulating warm air through the drying chamber. The moisture-laden air is then passed through a heat exchanger, where the moisture is condensed and removed. The dry air is reheated and returned to the drying chamber, creating a continuous cycle that effectively reduces drying times.

Advantages of Using Heat Pump Dryers for Food Drying

1. Energy Efficiency

One of the most significant advantages of heat pump dryers is their energy efficiency. By recycling air and using lower temperatures, these dryers consume less energy compared to conventional drying methods. This not only reduces operational costs but also minimizes the environmental impact of food processing.

2. Preservation of Nutritional Value

Heat pump dryers operate at lower temperatures, which helps preserve the nutritional value of food products. High temperatures can degrade vitamins and minerals, but with heat pump technology, food retains more of its natural goodness.

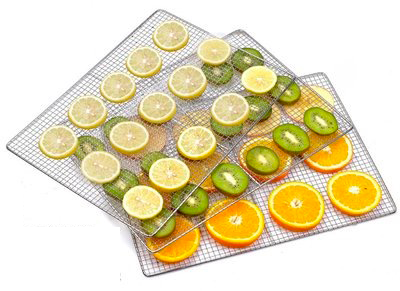

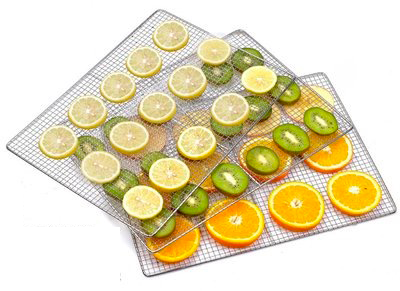

3. Improved Quality of Dried Products

The gentle drying process of heat pump dryers results in higher quality dried products. Foods dried with this method often have better color, texture, and flavor compared to those dried with traditional methods. This is particularly important for fruits, vegetables, and herbs, where appearance and taste are critical.

4. Versatility

Heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and herbs. This adaptability makes them an excellent choice for food manufacturers looking to diversify their product offerings.

5. Reduced Drying Times

While heat pump dryers are known for their energy efficiency, they also excel in reducing drying times. By optimizing the drying process and maintaining consistent temperatures, manufacturers can achieve faster drying without compromising quality.

Optimizing Drying Times with Heat Pump Technology

To maximize the efficiency of heat pump dryers and reduce drying times, several factors should be considered:

1. Pre-Treatment of Food

Pre-treating food before drying can significantly impact drying times. Techniques such as blanching, slicing, or soaking can help reduce moisture content and improve the overall drying process. For example, blanching vegetables before drying can help preserve color and texture while speeding up the drying process.

2. Proper Loading Techniques

How food is loaded into the dryer can affect airflow and drying efficiency. Ensuring that food items are evenly spaced and not overcrowded allows for better air circulation, leading to more uniform drying and reduced times.

3. Monitoring Humidity Levels

Maintaining optimal humidity levels within the drying chamber is crucial for efficient drying. Using humidity sensors can help monitor and adjust conditions in real-time, ensuring that the drying process remains effective.

4. Regular Maintenance

Regular maintenance of heat pump dryers is essential for optimal performance. Cleaning filters, checking seals, and ensuring that the heat exchanger is functioning correctly can help maintain efficiency and reduce drying times.

5. Utilizing Advanced Controls

Modern heat pump dryers come equipped with advanced control systems that allow for precise temperature and humidity management. Utilizing these features can help optimize the drying process and reduce overall drying times.

Case Studies: Successful Applications of Heat Pump Dryers

Case Study 1: Fruit Drying

A fruit processing company implemented heat pump dryers to enhance their drying process. By optimizing loading techniques and pre-treating fruits, they reduced drying times by 30% while maintaining the quality of their dried products. The company reported increased customer satisfaction and a boost in sales due to the superior quality of their dried fruits.

Case Study 2: Vegetable Drying

A vegetable manufacturer faced challenges with traditional drying methods, leading to inconsistent product quality. After switching to heat pump dryers, they achieved more uniform drying and reduced drying times by 25%. The improved quality of their dried vegetables allowed them to enter new markets and increase their product range.

Case Study 3: Herb Drying

An herb producer utilized heat pump technology to dry their products. By implementing advanced controls and monitoring humidity levels, they reduced drying times significantly while preserving the essential oils and flavors of their herbs. This led to higher market prices and increased demand for their products.

The Future of Food Drying Technology

As the demand for high-quality dried food products continues to grow, the food processing industry is increasingly turning to advanced technologies like heat pump dryers. These machines not only offer energy efficiency and improved product quality but also align with the global push for sustainable practices in food production.

Innovations in Heat Pump Technology

The future of heat pump dryers looks promising, with ongoing innovations aimed at enhancing their efficiency and capabilities. Manufacturers are exploring new materials for heat exchangers, improved insulation techniques, and smarter control systems that utilize artificial intelligence to optimize drying processes further.

Market Trends

The market for heat pump dryers is expected to expand as more food manufacturers recognize the benefits of this technology. With a growing emphasis on sustainability and energy conservation, heat pump dryers are likely to become the standard in food drying applications.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology. Their energy efficiency, ability to preserve nutritional value, and versatility make them an ideal choice for food manufacturers. By optimizing drying processes and utilizing advanced features, businesses can reduce drying times while maintaining the quality of their products. As a leading manufacturer of food drying machines, we are committed to providing innovative solutions that meet the needs of our clients in the global market.

Frequently Asked Questions

1. What is a heat pump dryer?

A heat pump dryer is a type of drying machine that uses a heat pump system to recycle air and remove moisture from food products efficiently.

2. How does a heat pump dryer differ from traditional dryers?

Heat pump dryers operate at lower temperatures and recycle air, making them more energy-efficient and better at preserving the quality of dried foods compared to traditional dryers.

3. Can heat pump dryers be used for all types of food?

Yes, heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and herbs.

4. How can I reduce drying times with a heat pump dryer?

To reduce drying times, consider pre-treating food, optimizing loading techniques, monitoring humidity levels, and utilizing advanced control systems.

5. What are the benefits of using heat pump dryers for food processing?

The benefits include energy efficiency, preservation of nutritional value, improved quality of dried products, versatility, and reduced drying times.