Content Menu

● Introduction to Freeze-Dried Food and Commercial Freeze Dryers

● Understanding the Freeze-Drying Process

>> The Role of Commercial Freeze Dryers

● The Krojenia Technology: Enhancing Freeze-Dried Food Production

>> Importance of Proper Food Preparation

● Applications of Freeze-Dried Food in Various Industries

>> 1. Food and Beverage Industry

>> 2. Pharmaceutical and Nutraceutical Industries

>> 3. Pet Food Industry

● Advantages of Using Commercial Freeze Dryers with Krojenia Technology

● Challenges in Freeze-Dried Food Production

● Innovations in Freeze-Drying Technology

>> 1. Improved Energy Efficiency

>> 2. Advanced Control Systems

>> 3. Integration of AI and Machine Learning

>> 4. Continuous Freeze-Drying Systems

● The Future of Freeze-Dried Food Production

● Choosing the Right Commercial Freeze Dryer

● The Role of Krojenia in Quality Control

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between freeze-drying and traditional dehydration?

>> 2. How long can freeze-dried foods last?

>> 3. Is freeze-dried food as nutritious as fresh food?

>> 4. What types of food can be freeze-dried?

>> 5. How does krojenia impact the freeze-drying process?

Introduction to Freeze-Dried Food and Commercial Freeze Dryers

In recent years, the food industry has witnessed a significant transformation with the advent of freeze-dried food technology. At the heart of this revolution are commercial freeze dryers, sophisticated machines that have redefined food preservation and processing. These industrial freeze-drying equipment pieces are not just changing how we preserve food; they're reshaping entire markets and creating new possibilities for food manufacturers worldwide.

Understanding the Freeze-Drying Process

Freeze-drying, also known as lyophilization, is a complex yet fascinating process. It involves removing water from food products through sublimation, where ice transitions directly from a solid to a gas state without passing through the liquid phase. This process preserves the structure and nutritional content of the food, resulting in a product that can be stored for extended periods without refrigeration.

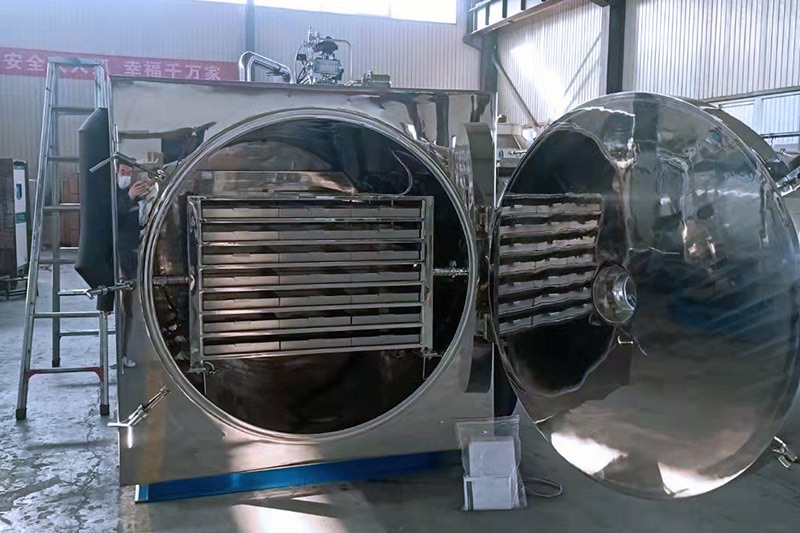

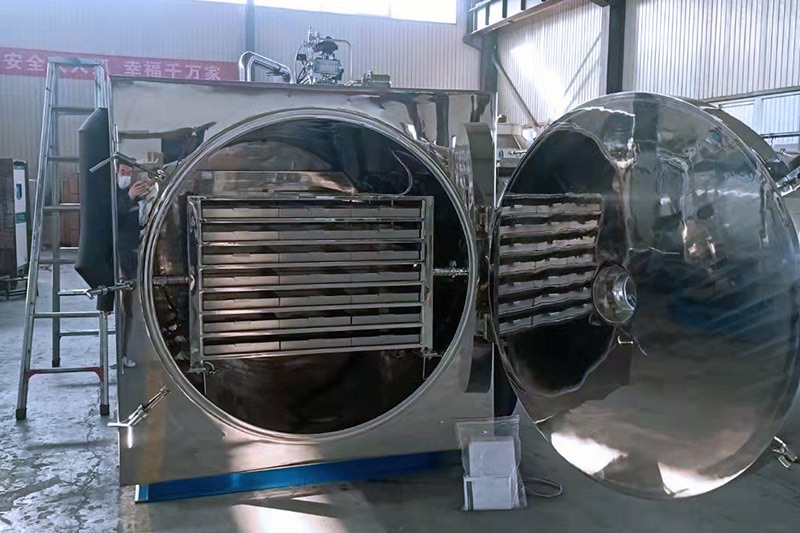

The Role of Commercial Freeze Dryers

Commercial freeze dryers are the workhorses of the freeze-dried food production industry. These machines are designed to handle large volumes of food, making them ideal for industrial-scale operations. A typical commercial freeze dryer consists of several key components:

1. A freezing chamber

2. A vacuum system

3. A heating system

4. Condenser plates

5. Control systems for monitoring and managing the process

These machines can process hundreds of kilograms of food in a single batch, making them essential for businesses looking to scale up their freeze-dried food production.

The Krojenia Technology: Enhancing Freeze-Dried Food Production

While the term "krojenia" might not be familiar to many in the English-speaking world, it plays a crucial role in the freeze-drying process. Krojenia, which translates to "cutting" in Polish, refers to the precise slicing and preparation of food before it enters the freeze-drying machine. This step is critical for ensuring uniform drying and maintaining the quality of the final product.

Importance of Proper Food Preparation

The krojenia process involves several key steps:

1. Cleaning and sanitizing the raw ingredients

2. Cutting or slicing the food into uniform pieces

3. Arranging the prepared food on trays for optimal freeze-drying

Proper krojenia ensures that each piece of food dries evenly, preserving its taste, texture, and nutritional value. It also helps optimize the efficiency of the freeze-drying process, reducing energy consumption and processing time.

Applications of Freeze-Dried Food in Various Industries

The versatility of freeze-dried food has led to its adoption across multiple industries:

1. Food and Beverage Industry

Freeze-dried fruits, vegetables, and meats are increasingly popular in the food and beverage sector. They're used in:

- Ready-to-eat meals

- Snack foods

- Instant soups and beverages

- Camping and outdoor foods

2. Pharmaceutical and Nutraceutical Industries

The pharmaceutical industry uses freeze-drying to preserve:

- Vaccines

- Antibiotics

- Probiotics

- Enzymes and proteins

3. Pet Food Industry

Pet owners are increasingly turning to freeze-dried pet foods for their nutritional benefits and convenience.

Advantages of Using Commercial Freeze Dryers with Krojenia Technology

The combination of commercial freeze dryers and krojenia technology offers numerous benefits:

1. Extended Shelf Life: Freeze-dried foods can last for years without refrigeration, reducing waste and improving logistics.

2. Nutrient Retention: The process preserves most of the food's original nutritional content, making it an excellent choice for health-conscious consumers.

3. Flavor Preservation: Freeze-dried foods retain much of their original flavor, often rehydrating to a taste similar to fresh products.

4. Weight Reduction: By removing water, freeze-drying significantly reduces the weight of food products, lowering transportation costs.

5. Versatility: The technology can be applied to a wide range of foods, from fruits and vegetables to meats and dairy products.

Challenges in Freeze-Dried Food Production

Despite its many advantages, freeze-dried food production faces several challenges:

1. High Initial Costs: Commercial freeze dryers and associated equipment require significant upfront investment.

2. Energy Consumption: The freeze-drying process is energy-intensive, which can impact operational costs.

3. Processing Time: Freeze-drying typically takes longer than other food preservation methods, which can limit production capacity.

4. Skill Requirements: Operating commercial freeze dryers and implementing proper krojenia techniques requires specialized training and expertise.

Innovations in Freeze-Drying Technology

The field of freeze-drying is continually evolving, with new innovations emerging regularly:

1. Improved Energy Efficiency

Newer models of commercial freeze dryers are designed to be more energy-efficient, reducing operational costs and environmental impact.

2. Advanced Control Systems

Modern freeze dryers feature sophisticated control systems that allow for precise management of the freeze-drying process, ensuring consistent quality across batches.

3. Integration of AI and Machine Learning

Some manufacturers are exploring the use of artificial intelligence and machine learning to optimize the freeze-drying process, predicting optimal settings for different types of food.

4. Continuous Freeze-Drying Systems

While most commercial freeze dryers operate in batches, continuous systems are being developed to increase production capacity and efficiency.

The Future of Freeze-Dried Food Production

As technology continues to advance, we can expect to see further improvements in freeze-dried food production:

1. Increased Automation: More aspects of the freeze-drying process, including krojenia, will likely become automated, improving efficiency and consistency.

2. Sustainable Practices: There will be a greater focus on developing eco-friendly freeze-drying processes and equipment.

3. Customization: Advanced technology may allow for more customized freeze-drying processes tailored to specific food products or nutritional requirements.

4. Miniaturization: While industrial-scale machines will continue to dominate, we may see the development of smaller, more affordable freeze dryers for small businesses and specialized applications.

Choosing the Right Commercial Freeze Dryer

For businesses looking to enter or expand their presence in the freeze-dried food market, selecting the right commercial freeze dryer is crucial. Factors to consider include:

1. Production Capacity: Ensure the machine can handle your current and projected production volumes.

2. Energy Efficiency: Look for models that offer good energy efficiency to keep operational costs down.

3. Versatility: Choose a machine that can handle the types of foods you plan to process.

4. Ease of Use: Consider the user interface and control systems, especially if you're new to freeze-drying technology.

5. Maintenance and Support: Opt for manufacturers that offer good after-sales support and easy access to spare parts.

The Role of Krojenia in Quality Control

Proper implementation of krojenia techniques is essential for maintaining product quality in freeze-dried food production. This includes:

1. Consistent Sizing: Ensuring that food pieces are cut to uniform sizes for even drying.

2. Appropriate Thickness: Slicing foods to the optimal thickness for efficient freeze-drying.

3. Careful Handling: Minimizing damage to the food structure during the cutting process.

4. Hygiene Standards: Maintaining strict cleanliness to prevent contamination.

Conclusion

The combination of commercial freeze dryers and krojenia technology has opened up new frontiers in food preservation and processing. As the demand for high-quality, long-lasting food products continues to grow, the importance of these technologies in the food industry is set to increase. From improving food security to enabling space exploration, freeze-dried foods are playing an increasingly vital role in our world. As technology continues to advance, we can expect to see even more innovative applications and improvements in this fascinating field.

Frequently Asked Questions

1. What is the difference between freeze-drying and traditional dehydration?

Answer: Freeze-drying removes water through sublimation, preserving the food's structure and nutrients better than traditional dehydration, which uses heat to evaporate water. Freeze-dried foods typically retain more of their original flavor, texture, and nutritional value.

2. How long can freeze-dried foods last?

Answer: When properly packaged and stored, freeze-dried foods can last for 25-30 years or even longer. This long shelf life makes them ideal for emergency food supplies, military rations, and space missions.

3. Is freeze-dried food as nutritious as fresh food?

Answer: Freeze-dried food retains most of its original nutritional value. The process preserves vitamins, minerals, and other nutrients better than many other preservation methods. However, some sensitive vitamins, like vitamin C, may degrade slightly during the process.

4. What types of food can be freeze-dried?

Answer: A wide variety of foods can be freeze-dried, including fruits, vegetables, meats, dairy products, complete meals, and even some beverages. However, foods with high fat content may not freeze-dry well as fats can become rancid over time.

5. How does krojenia impact the freeze-drying process?

Answer: Krojenia, or the proper cutting and preparation of food before freeze-drying, is crucial for ensuring even drying and maintaining product quality. Proper krojenia techniques result in uniform piece sizes, which allows for more efficient freeze-drying and a better final product.