Penetration type dryer machines are widely used in various industries, particularly in food processing, due to their efficiency and versatility. These machines are designed to dry products evenly, even when they are stacked together, making them ideal for large-scale operations. In this article, we will explore the common applications of penetration type dryer machines, focusing on their use in the food industry.

Introduction to Penetration Type Dryer Machines

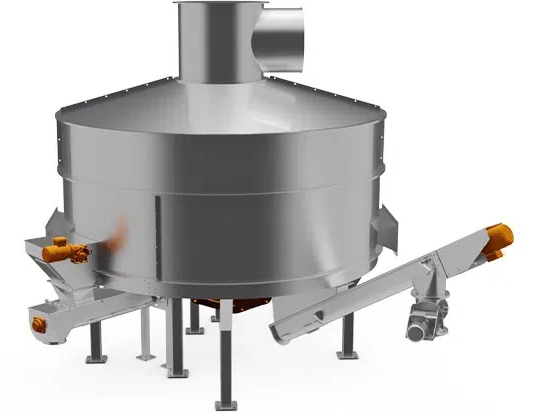

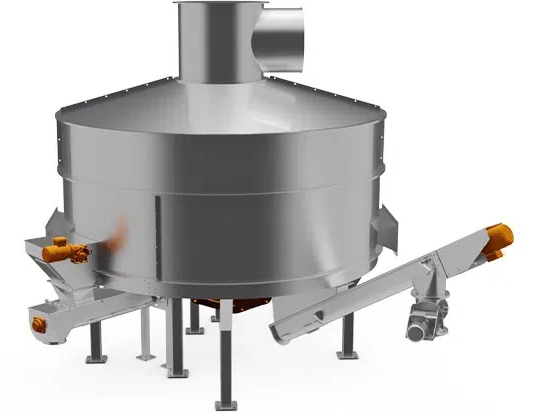

Penetration type dryers utilize a patented half-vacuum air duct design, which allows for uniform drying of products without direct contact. This technology is energy-efficient, using only about 25% of the electricity required by traditional dryers. The temperature can be adjusted from 18°C to 80°C, offering hot dry, cool dry, and dehumidification functions.

Key Features of Penetration Type Dryers

1. Energy Efficiency: Uses significantly less electricity compared to traditional dryers.

2. Temperature Control: Adjustable temperature range from 18°C to 80°C.

3. Drying Functions: Offers hot dry, cool dry, and dehumidification options.

4. Capacity: Suitable for capacities ranging from 300 kg to 10 tons.

Common Applications in Food Industry

Penetration type dryers are extensively used for drying various food products, including nuts, spices, seeds, and beans. Here are some of the common applications:

Nuts Drying

Nuts like peanuts, walnuts, and pistachios are commonly dried using penetration type dryers. These machines ensure that nuts are dried evenly without losing their flavor or texture. The controlled temperature prevents overheating, which can lead to rancidity.

Spices Drying

Spices such as cardamom, pepper, and chili are dried to preserve their aroma and flavor. The controlled temperature and humidity ensure that spices retain their quality and potency. This is crucial for maintaining the flavor profile in final products.

Seeds and Beans Drying

Seeds like sunflower seeds and pumpkin seeds, as well as beans, are dried to remove moisture, making them suitable for storage and further processing. Proper drying prevents mold growth and maintains nutritional value.

Other Applications

1. Fruit and Vegetable Drying: While not as common, penetration type dryers can also be used for drying fruits and vegetables, though they are more typically associated with heat pump dryers. Fruits like apricots and apples can be dried to make healthy snacks.

2. Coffee and Cocoa Beans: These are dried to enhance their flavor and aroma. Proper drying is essential for developing the complex flavors in coffee and cocoa.

How Penetration Type Dryers Work

The process involves stacking the products in layers within the dryer. Hot air is circulated through the layers using a half-vacuum system, ensuring even drying without direct contact. This method prevents overheating and maintains product quality.

Benefits of Using Penetration Type Dryers

1. Energy Efficiency: They consume significantly less energy than traditional dryers.

2. Uniform Drying: Ensures that products are dried evenly, even when stacked.

3. Flexibility: Can be used for a wide range of food products.

4. Cost-Effective: Reduces operational costs due to lower energy consumption.

Comparison with Other Drying Technologies

Other drying technologies include infrared dryers, direct dryers, and indirect dryers. Infrared dryers heat the surface of materials, while direct dryers use convection to transfer heat directly to the material. Indirect dryers keep the heat source separate from the material, which is beneficial for sensitive items.

Future Developments and Trends

The future of penetration type dryers involves integrating more advanced technologies to enhance efficiency and reduce environmental impact. This includes using renewable energy sources and improving insulation to minimize heat loss. Additionally, advancements in automation will allow for more precise control over drying conditions, further improving product quality.

Case Studies and Examples

Several companies have successfully implemented penetration type dryers in their operations. For instance, a major nut processing company in the United States uses these dryers to dry almonds and walnuts, achieving significant energy savings while maintaining product quality.

Maintenance and Troubleshooting

Regular maintenance is crucial to ensure the longevity and efficiency of penetration type dryers. This includes cleaning the air ducts, checking for leaks in the vacuum system, and ensuring proper temperature calibration. Common issues such as uneven drying or reduced airflow can often be resolved by checking these factors.

Conclusion

Penetration type dryer machines are versatile and efficient tools in the food industry, offering a wide range of applications from nuts and spices to seeds and beans. Their energy efficiency and ability to dry products evenly make them a preferred choice for large-scale food processing operations.

Frequently Asked Questions (FAQs)

1. What are the primary advantages of penetration type dryers over traditional dryers?

Penetration type dryers offer significant energy savings, using only about 25% of the electricity required by traditional dryers. They also provide uniform drying even when products are stacked together.

2. What types of food products are commonly dried using penetration type dryers?

Common products include nuts (peanuts, walnuts, pistachios), spices (cardamom, pepper), seeds (sunflower, pumpkin), and beans.

3. How does the temperature control in penetration type dryers work?

The temperature can be adjusted from 18°C to 80°C, allowing for hot dry, cool dry, and dehumidification functions. This flexibility ensures that different types of food products can be dried according to their specific requirements.

4. Are penetration type dryers suitable for large-scale operations?

Yes, they are suitable for large-scale operations with capacities ranging from 300 kg to 10 tons. Their efficiency and ability to handle stacked products make them ideal for commercial use.

5. What are some future developments expected in penetration type dryers?

Future developments are expected to focus on integrating renewable energy sources, improving insulation, and enhancing automation to reduce environmental impact and operational costs.

Citations:

[1] https://www.jimdry.com/integrated-stacked-type-dryer.html

[2] https://www.panasonic.com/mea/en/consumer/home-appliances/laundry/washer-dryer/na-s24ml1.html

[3] https://patents.google.com/patent/CN110207480A/zh

[4] https://www.dryeratech.com/penetration-type-dryer-machine.html

[5] https://www.aimheatpump.com/video/a-products-commercial-aim-large-capacity-heat-pump-dryer

[6] https://patents.google.com/patent/CN109252340A/zh

[7] https://www.iqsdirectory.com/articles/dryer/types-of-dryers.html

[8] https://www.panasonic.com/ae/consumer/home-appliances/laundry/washer-dryer/na-s16ml1.html

[9] https://www.aimheatpump.com/video/a-products-aim-chamber-trolley-type-heat-pump-dryer-large-commercial-food-dehydrator

[10] https://www.youtube.com/watch?v=OY2KovyLFog