Content Menu

● Introduction to Room Type Drying Machines

>> Benefits of Room Type Drying Machines

● Common Mistakes When Using Room Type Drying Machines

>> 1. Incorrect Temperature and Humidity Settings

>> 2. Overloading the Drying Chamber

>> 3. Not Rotating Trays During the Process

>> 4. Ignoring Maintenance Requirements

>> 5. Incorrect Material Handling

● Advanced Features of Room Type Drying Machines

>> Integration with Other Equipment

>> Customization Options

● Case Studies: Successful Implementation of Room Type Drying Machines

>> Benefits for Small-Scale Producers

● Conclusion

● FAQ

>> 1. What are the benefits of using room type drying machines over traditional drying methods?

>> 2. How do I ensure uniform drying when using a room type drying machine?

>> 3. What maintenance tasks are essential for room type drying machines?

>> 4. Can room type drying machines be customized for specific food products?

>> 5. How do I choose the right room type drying machine for my business?

● Citations:

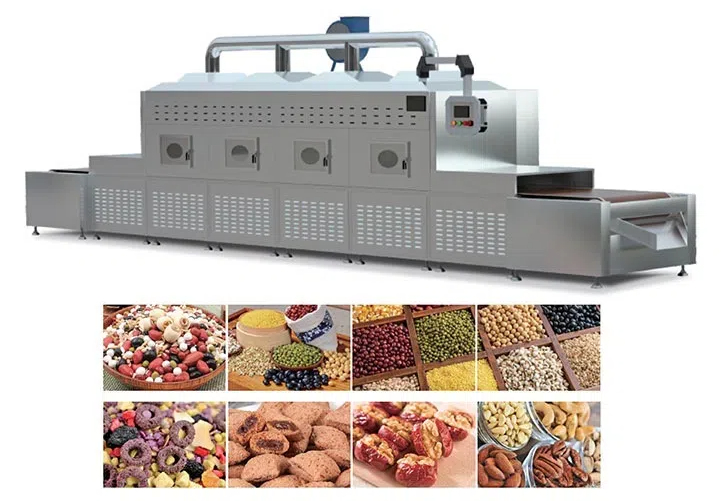

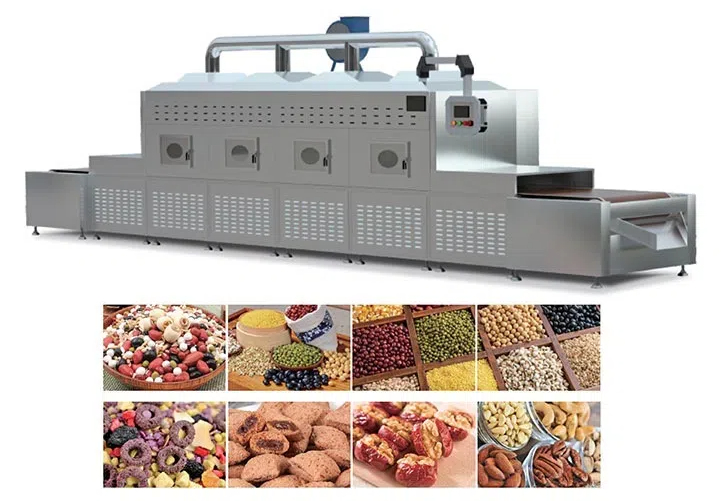

Room type drying machines are widely used in the food industry for drying various products such as fruits, vegetables, meats, and grains. These machines offer advantages like energy efficiency, uniform drying, and minimal manual intervention. However, despite their benefits, there are common mistakes that users should be aware of to ensure optimal performance and product quality.

Introduction to Room Type Drying Machines

Room type drying machines operate at lower temperatures compared to traditional drying methods, which helps preserve the nutritional content and flavor of food products. They are equipped with advanced control systems, allowing for precise monitoring and adjustment of drying parameters such as temperature and humidity. These machines can be integrated with other food processing equipment to create a seamless production line.

Benefits of Room Type Drying Machines

- Energy Efficiency: Room type drying machines are generally more energy-efficient compared to traditional drying methods. They often incorporate heat recovery systems, efficient air circulation mechanisms, and advanced insulation to minimize energy consumption.

- Consistent Product Quality: These machines provide uniform drying conditions, ensuring consistent product quality and reducing the risk of microbial growth due to moisture removal.

- Versatility: They can be used to dry a wide variety of food products, accommodating different shapes and sizes of food items.

Common Mistakes When Using Room Type Drying Machines

1. Incorrect Temperature and Humidity Settings

One of the most common mistakes is using incorrect temperature and humidity settings. Different foods require specific conditions to dry optimally. For example, fruits generally need lower temperatures, while meats require higher temperatures to ensure safety. Always refer to the machine's manual for specific recommendations.

2. Overloading the Drying Chamber

Overcrowding the drying chamber can lead to poor air circulation, causing uneven drying. It is essential to spread food evenly across the trays, leaving space between pieces to ensure consistent drying throughout the batch.

3. Not Rotating Trays During the Process

Most drying machines do not distribute heat evenly across all trays. To ensure all food dries evenly, it is crucial to rotate the trays periodically during the drying process.

4. Ignoring Maintenance Requirements

Regular maintenance is crucial for optimal performance. This includes cleaning and sanitizing the drying chamber and trays, inspecting and replacing air filters, and calibrating temperature and humidity sensors.

5. Incorrect Material Handling

Improper handling of materials can lead to uneven drying. Ensure that materials are evenly distributed and that the machine is used according to its specifications.

Advanced Features of Room Type Drying Machines

Modern room type drying machines often come with advanced features such as multi-stage drying capabilities, allowing for different temperature and humidity settings at various stages of the drying process. These features are particularly useful for products that require specific drying profiles to achieve optimal quality and texture.

Integration with Other Equipment

Room type drying machines can be integrated with automated loading and unloading systems, sorting and grading equipment, and packaging machines to streamline the production process. This integration not only enhances efficiency but also reduces labor costs and minimizes the risk of contamination.

Customization Options

Many room type drying machines offer customization options to cater to specific drying needs. For instance, some machines allow for the adjustment of air flow patterns to accommodate delicate or dense products. Additionally, advanced control systems can be programmed to mimic natural drying conditions, which is beneficial for preserving the natural flavors and textures of food products.

Case Studies: Successful Implementation of Room Type Drying Machines

Several food manufacturers have successfully integrated room type drying machines into their production lines, achieving significant improvements in product quality and operational efficiency. For example, a fruit drying company in Europe reported a 30% increase in production capacity and a 25% reduction in energy costs after switching to room type drying machines.

Benefits for Small-Scale Producers

Room type drying machines are not limited to large-scale industrial applications. Small-scale producers can also benefit from these machines, as they offer a cost-effective way to produce high-quality dried products. This is particularly important for artisanal food producers who need to maintain consistent quality while keeping costs manageable.

Conclusion

Room type drying machines are powerful tools in the food industry, offering efficiency, consistency, and versatility. However, to maximize their benefits, it is crucial to avoid common mistakes such as incorrect temperature settings, overloading, and neglecting maintenance. By understanding these pitfalls and utilizing the advanced features of these machines, food manufacturers can ensure high-quality dried products while maintaining operational efficiency.

FAQ

1. What are the benefits of using room type drying machines over traditional drying methods?

Room type drying machines offer several benefits, including energy efficiency, preservation of nutritional content, and consistent product quality. They also allow for year-round production, independent of weather conditions.

2. How do I ensure uniform drying when using a room type drying machine?

To ensure uniform drying, it is important to spread food evenly across the trays, rotate trays periodically, and maintain proper temperature and humidity settings.

3. What maintenance tasks are essential for room type drying machines?

Regular maintenance includes cleaning and sanitizing the drying chamber and trays, inspecting and replacing air filters, and calibrating temperature and humidity sensors.

4. Can room type drying machines be customized for specific food products?

Yes, modern room type drying machines often offer customizable parameters for optimal drying of different food products. They can be integrated with other equipment to meet specific production needs.

5. How do I choose the right room type drying machine for my business?

When choosing a room type drying machine, consider factors such as production capacity requirements, types of food products to be dried, available space, energy efficiency ratings, customization options, and budget constraints.

Citations:

[1] https://sedpharma.com/news-events/how-to-freeze-dry-food/

[2] https://www.dryeratech.com/benefits-of-room-type-drying-machines.html

[3] https://www.freshtimefoods.com/post/dehydrating-tips-common-mistakes-to-avoid

[4] https://aradmachineryco.com/catproduct/Cabinet-dryer

[5] https://www.youtube.com/watch?v=-kDPB6X2-qo

[6] https://gcwgandhinagar.com/econtent/document/1588156026Unit%20V%20Types%20of%20dryers%20and%20their%20applications.pdf

[7] https://aqualab.com/en/moisture-content/drying-101-mistakes-kill-your-yields

[8] https://en.fdsp.com/faq/3590.html

[9] https://empiredrying.com/freeze-drying-problems-and-mistakes/

[10] https://www.ike.cn/leave-cabinet-dryer-for-food-for-vegetable-ike.html

[11] https://www.youtube.com/watch?v=A5Nf2P7-nbU

[12] https://airtekdehydrator.com/blog/noodle-drying-machine/

[13] https://dynamox.net/en/blog/industrial-dryers-types-faults-and-how-to-monitor-them

[14] https://www.easy-food-dehydrating.com/common-mistakes-when-dehydrating-food.html

[15] https://www.youtube.com/watch?v=Namf-Ddo_Xo

[16] https://www.dryeratech.com/choosing-the-right-room-type-drying-machine-for-your-needs.html

[17] https://www.bryair.com/industry/snack-food-processing-and-packaging/

[18] https://www.tastingtable.com/1671930/mistakes-avoid-dehydrator/

[19] https://www.shutterstock.com/search/food-dryer

[20] https://www.dryeratech.com/room-type-drying-machines-for-different-industries.html

[21] https://www.istockphoto.com/photos/food-dryer