Content Menu

● What is a Condenser Dryer?

>> Advantages of Condenser Dryers

>> Disadvantages of Condenser Dryers

● What is a Heat Pump Dryer?

>> Advantages of Heat Pump Dryers

>> Disadvantages of Heat Pump Dryers

● Key Differences Between Condenser Dryers and Heat Pump Dryers

● Choosing the Right Dryer for Your Needs

● Real-World Applications

● Conclusion

● FAQ

>> 1. What is the main difference between a condenser dryer and a heat pump dryer?

>> 2. Are heat pump dryers worth the higher initial investment?

>> 3. Can I use either type of dryer for all kinds of food?

>> 4. How much energy does each type of dryer consume?

>> 5. What maintenance do these dryers require?

In the world of food drying, two popular technologies dominate the market: condenser dryers and heat pump dryers. Understanding the differences between these two types of dryers is crucial for manufacturers, wholesalers, and brand owners in the food industry. This article will explore the functionalities, advantages, and disadvantages of both condenser dryers and heat pump dryers, helping you make an informed decision for your food drying needs.

What is a Condenser Dryer?

A condenser dryer is a type of dryer that uses a heat exchanger to condense moisture from the air inside the drum. The process involves heating the air, which then absorbs moisture from the food being dried. Once the air is saturated with moisture, it passes through a condenser where the moisture is removed, allowing dry air to circulate back into the drum.

Advantages of Condenser Dryers

- Quick Drying Time: Condenser dryers generally have faster drying times compared to heat pump dryers due to higher operating temperatures. This is particularly beneficial in commercial settings where time efficiency is critical.

- Ease of Installation: These dryers do not require external venting, making them easier to install in various locations. This flexibility allows businesses to optimize their workspace without worrying about ductwork.

- Cost-Effective: Typically, condenser dryers are less expensive than heat pump models, making them an attractive option for budget-conscious businesses. The lower upfront costs can be appealing for startups or smaller operations.

- Simplicity of Operation: Condenser dryers often have straightforward controls and require less technical knowledge to operate effectively. This can reduce training time for staff and streamline operations.

Disadvantages of Condenser Dryers

- Energy Consumption: They tend to consume more energy than heat pump dryers, leading to higher operational costs over time. This can be a significant factor for businesses looking to minimize expenses.

- Heat Emission: The high temperatures can lead to increased ambient heat in the surrounding area, which may not be ideal in all settings. In warmer climates or enclosed spaces, this can create uncomfortable working conditions.

- Moisture Management: While condenser dryers remove moisture from the air inside the drum, they may not effectively manage humidity levels in larger spaces, potentially leading to condensation issues elsewhere.

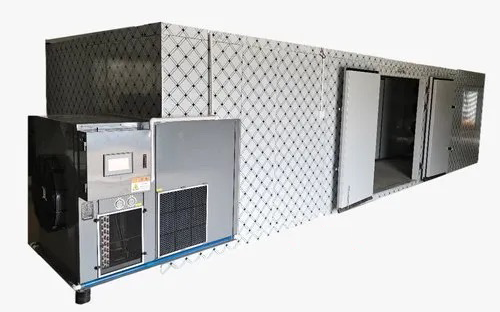

What is a Heat Pump Dryer?

A heat pump dryer operates on a different principle. It uses a refrigeration cycle to extract moisture from food. The dryer heats air using a compressor and then circulates this warm air through the drum. After absorbing moisture, the air passes through an evaporator where the moisture is condensed and removed.

Advantages of Heat Pump Dryers

- Energy Efficiency: Heat pump dryers are significantly more energy-efficient than condenser dryers. They use lower temperatures and recycle hot air within the system, which can lead to substantial savings on energy bills over time.

- Gentler Drying Process: The lower drying temperatures help preserve the quality and nutritional value of food products. This is particularly important for health-conscious consumers who prioritize nutrient retention in dried foods.

- Environmentally Friendly: These dryers produce less carbon footprint due to their energy efficiency. As sustainability becomes increasingly important in food production, heat pump dryers align well with eco-friendly practices.

- Versatility: Heat pump dryers are suitable for a wide range of products, including fruits, vegetables, herbs, and meats. Their ability to control temperature precisely allows for tailored drying processes that can enhance product quality.

Disadvantages of Heat Pump Dryers

- Longer Drying Times: They generally take longer to dry food compared to condenser dryers due to lower operating temperatures. Businesses with high throughput demands may find this challenging.

- Higher Initial Cost: The upfront investment for heat pump dryers can be substantial, which may deter some businesses from choosing this option. However, this cost can be offset by long-term energy savings.

- Complex Maintenance: Heat pump systems can be more complex than condenser systems and may require specialized maintenance or repairs. Businesses need to consider whether they have access to qualified technicians.

Key Differences Between Condenser Dryers and Heat Pump Dryers

To better understand which dryer might be right for your food processing needs, let's compare their key features:

| Feature | Condenser Dryer | Heat Pump Dryer |

| Energy Efficiency | Lower | Higher |

| Initial Cost | Lower | Higher |

| Drying Time | Faster | Slower |

| Operating Temperature | Higher | Lower |

| Environmental Impact | Higher carbon footprint | Lower carbon footprint |

| Installation Complexity | Easier | More complex |

Choosing the Right Dryer for Your Needs

When selecting between a condenser dryer and a heat pump dryer for your food drying business, consider the following factors:

1. Volume of Production: If you require quick drying for large batches of food, a condenser dryer may be more suitable. However, if you prioritize energy efficiency and product quality over speed, a heat pump dryer is ideal.

2. Budget Constraints: Evaluate your budget not only for initial purchase but also for long-term operational costs. While heat pump dryers are more efficient, their higher upfront cost may not fit every business model.

3. Space Availability: Consider your installation space. If ventilation is limited or if you want flexibility in placement, a condenser dryer might be more appropriate.

4. Product Type: Different foods have varying drying requirements. For delicate items that require gentle handling and lower temperatures, a heat pump dryer would be beneficial.

5. Environmental Considerations: If sustainability is a priority for your business, investing in a heat pump dryer can help reduce your environmental impact over time.

6. Regulatory Compliance: Depending on your location and type of food products processed, there may be regulations regarding energy use or emissions that could influence your choice between these two types of dryers.

7. Future Expansion Plans: If you anticipate growth in production capacity or diversification into new product lines that require different drying conditions, consider which type of dryer will best accommodate those changes without requiring significant additional investment.

Real-World Applications

Understanding how these technologies are applied in real-world scenarios can provide further insight into their effectiveness:

- In commercial fruit drying operations where speed is essential, many companies opt for condenser dryers due to their rapid drying capabilities. However, they must balance this with energy costs and potential impacts on product quality.

- Conversely, businesses focused on organic or health foods often prefer heat pump dryers because they maintain nutritional integrity while being environmentally friendly. These operations might take longer but benefit from higher quality outputs that appeal to health-conscious consumers.

Conclusion

In conclusion, both condenser dryers and heat pump dryers have their unique advantages and disadvantages when it comes to food drying applications. The choice ultimately depends on your specific needs regarding production volume, budget constraints, space availability, product type, environmental considerations, regulatory compliance, and future expansion plans. By carefully evaluating these factors alongside real-world applications of each technology, you can select the most suitable drying technology for your business.

FAQ

1. What is the main difference between a condenser dryer and a heat pump dryer?

The main difference lies in their operation; condenser dryers use high temperatures to remove moisture quickly but are less energy-efficient than heat pump dryers that operate at lower temperatures using a refrigeration cycle.

2. Are heat pump dryers worth the higher initial investment?

Yes, if you prioritize energy efficiency and want to reduce long-term operational costs while maintaining product quality.

3. Can I use either type of dryer for all kinds of food?

While both types can dry various foods, delicate items may benefit more from heat pump dryers due to their gentler drying process.

4. How much energy does each type of dryer consume?

Condenser dryers typically consume more energy due to higher operating temperatures compared to heat pump dryers that recycle hot air and operate at lower temperatures.

5. What maintenance do these dryers require?

Both types require regular cleaning of filters and condensers; however, heat pump dryers may need additional attention to their refrigerant systems depending on usage frequency.