Content Menu

● Introduction

● Understanding Food Drying

>> Types of Food Dryers

● Hang Type Dryers: A Detailed Exploration

>> Features

>> Advantages

>> Disadvantages

● Traditional Dryers: A Deep Dive

>> Features

>> Advantages

>> Disadvantages

● Real-World Applications and Case Studies

● Factors to Consider When Choosing a Dryer

● The OEM Perspective: Customization and Integration

● Conclusion

● FAQs

>> 1. What is the primary difference between hang type and traditional dryers?

>> 2. Are hang type dryers more energy-efficient?

>> 3. Can I dry all types of food in both dryer types?

>> 4. What are the maintenance requirements for each dryer type?

>> 5. How do I decide which dryer is best for my business?

● Citations:

Introduction

In the ever-evolving landscape of food processing and preservation, choosing the right drying technology is paramount. Among the myriad options available, hang type dryers and traditional dryers stand out as two distinct categories, each offering unique advantages and catering to different needs. This article delves into a comprehensive comparison of these two dryer types, exploring their features, benefits, drawbacks, and applications. Whether you're a food manufacturer, wholesaler, or OEM service provider, understanding the nuances of these technologies is crucial for making informed decisions that align with your business objectives.

Understanding Food Drying

Food drying is an age-old technique that remains vital in modern food preservation. By removing moisture from food, the drying process inhibits the growth of microorganisms, such as bacteria, yeasts, and molds, which are responsible for spoilage. This extends the shelf life of food products, reduces transportation costs by decreasing weight, and preserves essential nutrients and flavors.

Types of Food Dryers

1. Hang Type Dryers: These dryers utilize a vertical structure where food items are hung on racks or hooks. Warm air is then circulated around the hanging food items, facilitating even moisture evaporation.

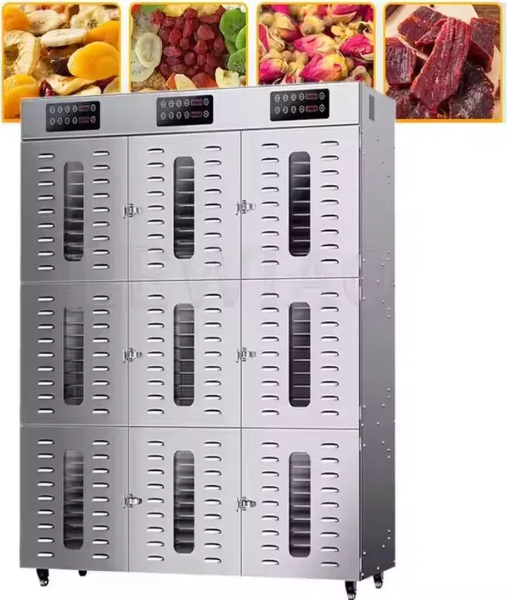

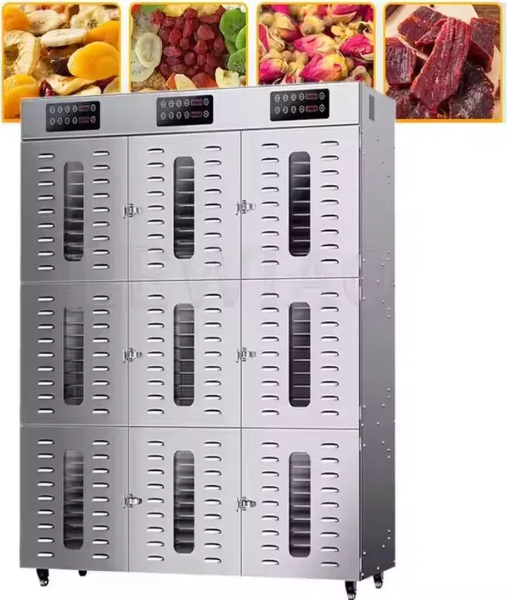

2. Traditional Dryers: Encompassing a broader category, traditional dryers typically include tumble dryers or cabinet dryers. These machines employ a rotating drum or static chamber in conjunction with heated air to dry food products.

Hang Type Dryers: A Detailed Exploration

Hang type dryers, as the name suggests, involve suspending food items within a chamber while circulating heated air around them. This method ensures uniform drying and is particularly effective for delicate foods.

Features

- Vertical Structure: Hang type dryers are characterized by their vertical design, which optimizes space utilization.

- Air Circulation System: These dryers incorporate sophisticated air circulation systems that ensure even distribution of warm air throughout the chamber.

- Temperature and Humidity Controls: Precise controls allow operators to adjust temperature and humidity levels, optimizing the drying process for different food types.

Advantages

- Energy Efficiency: Hang type dryers generally consume less energy compared to traditional dryers due to their efficient air circulation and controlled environment.

- Gentle Drying: The gentle airflow minimizes physical damage to delicate food items, preserving their texture and appearance.

- Versatility: Suitable for a wide range of food products, including fruits, vegetables, herbs, and even certain types of meat and seafood.

- Low Maintenance: Fewer moving parts translate to lower maintenance costs and reduced downtime.

Disadvantages

- Longer Drying Times: Depending on the food type, humidity, and temperature settings, drying times can be longer compared to traditional methods.

- Initial Cost: The upfront investment for hang type dryers may be higher compared to some traditional dryer models.

Traditional Dryers: A Deep Dive

Traditional dryers encompass a variety of designs, but they generally involve a rotating drum or a static chamber where food items are exposed to heated air.

Features

- Rotating Drum Design: Many traditional dryers feature a rotating drum that tumbles the food items, promoting uniform drying.

- High Capacity: These machines typically have larger capacities, making them suitable for bulk drying operations.

- Advanced Control Systems: Modern traditional dryers often come with advanced control systems for precise temperature, humidity, and airflow management.

Advantages

- Faster Drying Times: The combination of heat and tumbling action allows for quicker moisture removal, making them ideal for high-volume operations.

- User-Friendly Controls: Intuitive control systems simplify operation and allow for precise adjustments based on the specific food being dried.

- Cost-Effective for Large Volumes: The ability to dry large quantities of food quickly can make traditional dryers a cost-effective solution for businesses with high production demands.

Disadvantages

- Higher Energy Consumption: Traditional dryers tend to use more energy due to their operational mechanics and heating requirements.

- Potential for Damage: The tumbling action can cause physical damage to fragile foods, limiting their suitability for delicate items.

- Greater Maintenance Requirements: More moving parts and complex systems can lead to higher maintenance costs and potential downtime.

Real-World Applications and Case Studies

To further illustrate the practical differences between hang type and traditional dryers, let's consider a few real-world applications and case studies:

1. Herb Drying: A small-scale herb farm specializing in organic basil and oregano uses a hang type dryer. The gentle airflow preserves the delicate essential oils and maintains the vibrant color of the herbs, resulting in a high-quality product that commands a premium price.

2. Fruit Chip Manufacturing: A large-scale fruit chip manufacturer utilizes traditional dryers with rotating drums. The high capacity and faster drying times allow them to process tons of apples, bananas, and mangoes efficiently, meeting the demands of a competitive market.

3. Vegetable Dehydration: A vegetable processing plant that supplies dehydrated vegetables to soup manufacturers employs both types of dryers. Hang type dryers are used for delicate leafy greens like spinach and kale, while traditional dryers are used for root vegetables like carrots and potatoes.

Factors to Consider When Choosing a Dryer

When deciding between hang type and traditional dryers, several factors should be carefully considered:

- Type of Food: Delicate foods that are prone to damage benefit from the gentle airflow of hang type dryers, while robust foods that require faster drying times are better suited for traditional dryers.

- Volume Requirements: Businesses with high-volume production needs may find traditional dryers more efficient, while smaller operations can benefit from the energy efficiency and versatility of hang type dryers.

- Energy Efficiency Goals: Companies committed to sustainable practices should prioritize hang type dryers due to their lower energy consumption.

- Budget Constraints: The initial cost, operating costs, and maintenance costs should all be factored into the decision-making process.

- Space Availability: Hang type dryers typically require less floor space due to their vertical design, making them ideal for facilities with limited space.

The OEM Perspective: Customization and Integration

For OEM (Original Equipment Manufacturer) service providers like us, understanding the nuances of both hang type and traditional dryers is essential for delivering customized solutions to our clients. We collaborate closely with food processing equipment brands, wholesalers, and manufacturers to develop tailored drying systems that meet their specific requirements.

This involves:

- Needs Assessment: Understanding the client's production volume, product specifications, and budget.

- Design and Engineering: Developing a drying system that optimizes efficiency, capacity, and quality.

- Manufacturing and Assembly: Utilizing high-quality components and adhering to strict manufacturing standards.

- Installation and Training: Providing on-site installation and training to ensure smooth operation.

- Ongoing Support: Offering maintenance, repairs, and technical support to maximize the lifespan of the equipment.

Conclusion

The choice between hang type and traditional dryers is not a one-size-fits-all decision. It hinges on a careful evaluation of factors such as the type of food being dried, volume requirements, energy efficiency preferences, budget constraints, and space limitations. Hang type dryers offer energy efficiency and gentle drying ideal for delicate items, while traditional dryers provide speed and capacity for bulk operations.

For OEM service providers, the key lies in offering customized solutions that precisely meet the needs of our clients. By understanding the strengths and weaknesses of each dryer type, we can deliver drying systems that optimize productivity, quality, and profitability.

Ultimately, the right choice will optimize food drying processes for better quality products, increased efficiency, and a stronger bottom line.

FAQs

1. What is the primary difference between hang type and traditional dryers?

Hang type dryers utilize vertical space with air circulation around hung items, while traditional dryers often involve tumbling mechanisms in a horizontal drum.

2. Are hang type dryers more energy-efficient?

Yes, hang type dryers typically consume less energy due to their design and operation compared to traditional dryers.

3. Can I dry all types of food in both dryer types?

Both dryer types can accommodate various foods; however, delicate items may fare better in hang type dryers due to gentler airflow.

4. What are the maintenance requirements for each dryer type?

Hang type dryers generally have lower maintenance needs due to fewer moving parts compared to traditional dryers which may require more frequent upkeep.

5. How do I decide which dryer is best for my business?

Consider factors such as the types of food you process, required drying times, energy costs, space availability, and your budget when making a decision.

Citations:

[1] https://www.montpellier-appliances.com/tumble-dryer-settings-features-explained/

[2] https://patents.google.com/patent/CN110207480A/zh

[3] https://www.nimoverken.com/en/landningssidor/drying-cabinet-or-tumble-dryer-which-option-is-best-for-drying-clothes/

[4] https://patents.google.com/patent/WO2017197612A1/zh

[5] https://www.cda.co.uk/laundry/condenser-vs-vented/

[6] https://patents.google.com/patent/WO2022068971A1/zh

[7] https://www.thegoodguys.com.au/buying-guide/dryer-buying-guide

[8] https://patents.google.com/patent/CN1405396A/zh