Content Menu

● Introduction to Food Dehydration Machines

● Understanding the Basics of Food Dehydration

>> How Machines to Make Dried Food Work

● Types of Machines to Make Dried Food

>> Home Food Dehydration Systems

>> Commercial Food Dehydrators

>> Industrial Dried Food Production Equipment

● Features to Look for in a Machine to Make Dried Food

>> Adjustable Temperature Control

>> Even Heat Distribution

>> Expandable Capacity

>> Timer and Auto Shut-off

>> Noise Level

● Best Food Drying Equipment for Different Needs

>> For Home Use

>> For Commercial Use

>> For Industrial Use

● Energy-Efficient Food Dehydrators

● Multi-Tray Food Drying Appliances

● Professional Food Dehydration Technology

>> Infrared Drying Technology

>> Freeze-Drying Technology

>> Microprocessor-Controlled Systems

● Affordable Food Drying Solutions

● Tips for Using Machines to Make Dried Food

● Maintenance of Food Drying Machines

● The Future of Machines to Make Dried Food

● Conclusion

● Frequently Asked Questions

>> 1. What types of food can I dry using a machine to make dried food?

>> 2. How long does it take to dry food using a machine?

>> 3. Are machines to make dried food energy-efficient?

>> 4. How do I clean my machine to make dried food?

>> 5. Can I use a machine to make dried food for commercial purposes?

Introduction to Food Dehydration Machines

In recent years, the popularity of dried foods has skyrocketed, leading to increased interest in machines to make dried food. These ingenious devices, also known as food dehydrators, have revolutionized the way we preserve food, offering a convenient and efficient method to extend the shelf life of various food items. Whether you're a home cooking enthusiast or a large-scale food producer, there's a machine to make dried food that suits your needs.

Understanding the Basics of Food Dehydration

Before delving into the specifics of machines to make dried food, it's essential to understand the basic principles of food dehydration. The process involves removing moisture from food items, which inhibits the growth of bacteria, yeasts, and molds. This preservation method not only extends the shelf life of food but also concentrates flavors and maintains nutritional value.

How Machines to Make Dried Food Work

A typical machine to make dried food operates by circulating warm air around the food items. The warmth causes the moisture in the food to evaporate, while the air circulation helps to carry the moisture away. Most modern food dehydrators consist of the following components:

1. Heating element

2. Fan for air circulation

3. Trays or racks to hold food

4. Adjustable thermostat

5. Timer (in some models)

Types of Machines to Make Dried Food

There are various types of machines to make dried food available in the market, catering to different needs and scales of operation.

Home Food Dehydration Systems

These machines to make dried food are designed for personal or family use. They typically have a compact design and can handle small to medium batches of food. Home food dehydration systems are perfect for those who want to make their own dried fruits, vegetables, herbs, or jerky.

Commercial Food Dehydrators

For small businesses or those who need to dry larger quantities of food, commercial food dehydrators offer increased capacity and efficiency. These machines to make dried food often feature multiple trays and more powerful heating elements and fans.

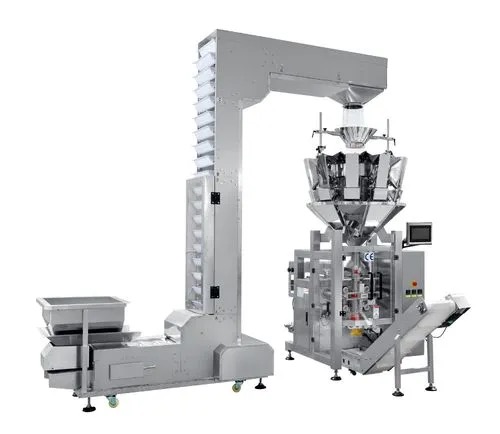

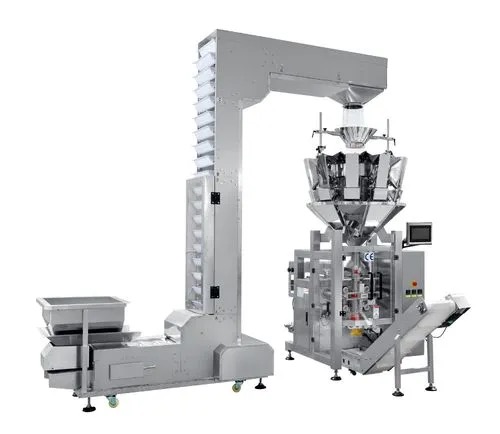

Industrial Dried Food Production Equipment

Large-scale food producers rely on industrial-grade machines to make dried food. These systems can handle massive quantities of food and often incorporate advanced features for precise control over the drying process.

Features to Look for in a Machine to Make Dried Food

When choosing a machine to make dried food, consider the following features:

Adjustable Temperature Control

Different foods require different drying temperatures. A good machine to make dried food should offer adjustable temperature settings, typically ranging from 95°F to 165°F (35°C to 74°C).

Even Heat Distribution

Look for machines that provide consistent heat distribution across all trays to ensure uniform drying.

Expandable Capacity

Some food dehydrators allow you to add extra trays, increasing the drying capacity as needed.

Timer and Auto Shut-off

A built-in timer with auto shut-off functionality can be incredibly convenient, especially for longer drying sessions.

Noise Level

Since machines to make dried food often run for extended periods, consider the noise level, especially if you plan to use it in a home setting.

Best Food Drying Equipment for Different Needs

Let's explore some of the best machines to make dried food for various purposes:

For Home Use

1. Excalibur 3926TB: Known for its large capacity and precise temperature control.

2. NESCO Gardenmaster: Offers expandable capacity and even drying.

3. Cuisinart DHR-20: Compact and affordable, perfect for beginners.

For Commercial Use

1. STX International DEH-1200W-XLS: Features 12 trays and digital controls.

2. LEM Products 1153: Ideal for medium-scale operations with its 10 trays.

For Industrial Use

1. Omron Industrial Food Dehydrator: Designed for large-scale, continuous operation.

2. Guangzhou Jiang Nan Machinery: Offers customizable solutions for industrial drying needs.

Energy-Efficient Food Dehydrators

As energy costs rise and environmental concerns grow, energy-efficient machines to make dried food have gained popularity. These models often feature:

1. Improved insulation to retain heat

2. LED lighting instead of incandescent bulbs

3. Smart sensors to optimize drying time and temperature

4. Solar-powered options for off-grid use

Multi-Tray Food Drying Appliances

Multi-tray food drying appliances offer versatility and efficiency. These machines to make dried food typically feature:

1. Multiple removable trays

2. Adjustable tray spacing

3. Different tray materials for various food types

4. Easy-to-clean designs

Professional Food Dehydration Technology

Professional-grade machines to make dried food incorporate advanced technologies to enhance the drying process:

Infrared Drying Technology

Some high-end food dehydrators use infrared technology to dry food more efficiently and evenly.

Freeze-Drying Technology

While not strictly a "dehydrator," freeze-dryers are advanced machines to make dried food that preserve the structure and nutritional content of food better than traditional dehydration methods.

Microprocessor-Controlled Systems

Advanced machines to make dried food often feature microprocessor-controlled systems for precise temperature and humidity control.

Affordable Food Drying Solutions

For those on a budget, there are several affordable machines to make dried food available:

1. Entry-level stackable dehydrators

2. Compact, single-tray models

3. DIY food dehydrator kits

While these may lack some advanced features, they can still produce excellent dried foods at a fraction of the cost of high-end models.

Tips for Using Machines to Make Dried Food

To get the most out of your machine to make dried food, consider these tips:

1. Prepare food uniformly: Cut fruits and vegetables into even slices for consistent drying.

2. Arrange food properly: Leave space between food items for proper air circulation.

3. Rotate trays: For even drying, rotate trays periodically during the drying process.

4. Pre-treat fruits: Dip fruits prone to browning in lemon juice or ascorbic acid solution.

5. Store dried foods properly: Use airtight containers and store in a cool, dark place.

Maintenance of Food Drying Machines

Proper maintenance of your machine to make dried food is crucial for longevity and optimal performance:

1. Clean trays and interior after each use

2. Check and clean air filters regularly

3. Inspect heating elements and fans periodically

4. Keep the exterior clean and dust-free

5. Follow manufacturer's guidelines for deep cleaning and maintenance

The Future of Machines to Make Dried Food

The technology behind machines to make dried food continues to evolve. Future trends may include:

1. Smart, Wi-Fi-enabled dehydrators

2. More energy-efficient models

3. Integration with other kitchen appliances

4. Advanced sensors for optimal drying

5. Improved user interfaces and controls

Conclusion

Machines to make dried food have come a long way from simple sun-drying techniques. Today, whether you're a home enthusiast or an industrial producer, there's a perfect food dehydrator out there for you. By understanding the features, types, and best practices for using these machines, you can unlock a world of delicious, nutritious, and long-lasting dried foods. As technology continues to advance, we can expect even more innovative and efficient machines to make dried food in the future.

Frequently Asked Questions

1. What types of food can I dry using a machine to make dried food?

Answer: Machines to make dried food can be used for a wide variety of foods, including fruits, vegetables, herbs, meats (for jerky), and even some dairy products like yogurt. Popular choices include apples, bananas, tomatoes, beef, and herbs like basil and oregano.

2. How long does it take to dry food using a machine?

Answer: The drying time can vary greatly depending on the food type, its water content, the thickness of the slices, and the specific machine you're using. Generally, herbs might take 2-4 hours, while fruits can take 6-12 hours, and meats for jerky can take up to 15 hours or more.

3. Are machines to make dried food energy-efficient?

Answer: Many modern machines to make dried food are designed with energy efficiency in mind. While they do use electricity continuously for several hours, they typically consume less energy than an oven. Some models are specifically marketed as energy-efficient, using advanced technologies to minimize power consumption.

4. How do I clean my machine to make dried food?

Answer: Most machines to make dried food have removable trays that can be washed with warm, soapy water. The interior can be wiped down with a damp cloth. Always unplug the machine before cleaning and avoid getting water on the heating element or fan. Some models have dishwasher-safe parts, but always check the manufacturer's instructions.

5. Can I use a machine to make dried food for commercial purposes?

Answer: Yes, there are machines to make dried food specifically designed for commercial use. These typically have larger capacities, more powerful fans and heating elements, and may include features like programmable settings and data logging for consistent results. However, if you're planning to sell dried foods, make sure to check local food safety regulations and obtain any necessary certifications.