Content Menu

● Introduction to Food Dehydration

● Understanding Food Air Drying Machines

>> Types of Food Dehydrators

● The Science Behind Food Dehydration

>> Hot Air Food Preservation

● Benefits of Using Food Air Drying Machines

● Fruit and Vegetable Dehydration

>> Popular Fruits for Dehydration

>> Vegetables That Dehydrate Well

● Energy-Efficient Food Drying

>> Features of Energy-Efficient Dehydrators

● Multi-Tray Food Dehydrators

>> Advantages of Multi-Tray Systems

● Stainless Steel Food Dryers

>> Benefits of Stainless Steel Construction

● Food Drying Technology Advancements

>> Recent Innovations

● Home Food Dehydration Techniques

>> Tips for Successful Home Dehydration

● Conclusion

● Frequently Asked Questions

>> 1. What are the best foods to dehydrate?

>> 2. How long does the dehydration process typically take?

>> 3. Are food dehydrators energy-efficient?

>> 4. How do I clean and maintain my food dehydrator?

>> 5. Can I dehydrate different foods at the same time?

Introduction to Food Dehydration

Food dehydration is an ancient preservation technique that has stood the test of time. In today's modern world, this age-old practice has been revolutionized by the introduction of food air drying machines, also known as food dehydrators. These innovative appliances have transformed the way we preserve food, offering a convenient and efficient method to extend the shelf life of various food products while maintaining their nutritional value and flavor.

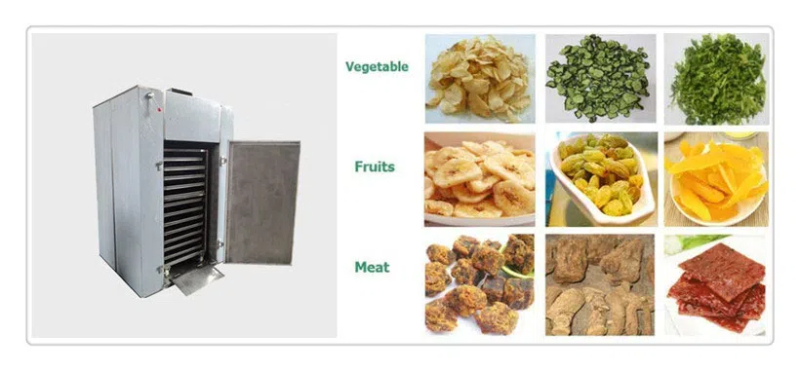

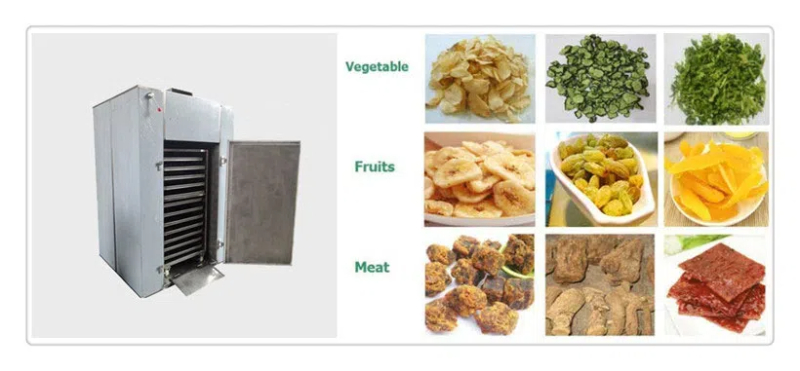

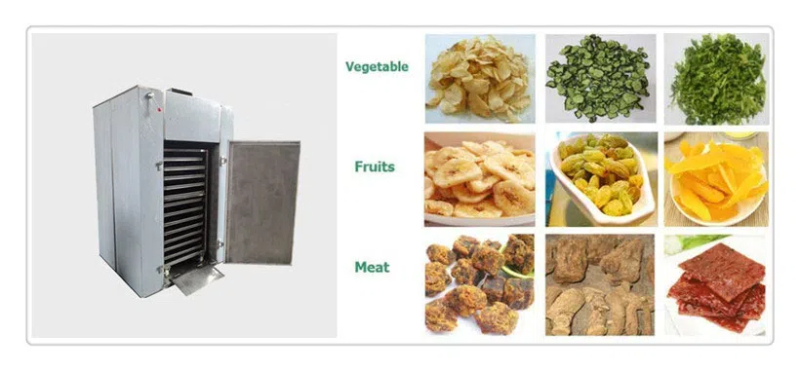

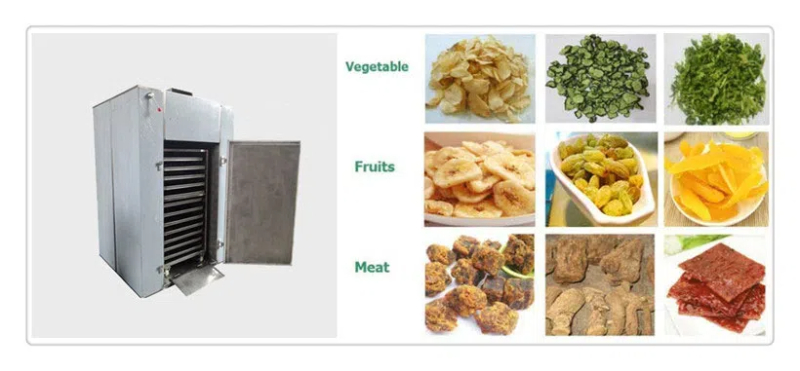

Understanding Food Air Drying Machines

Food air drying machines, or food dehydrators, are specialized appliances designed to remove moisture from food items. They work by circulating warm air around the food, gradually evaporating the water content. This process not only preserves the food but also concentrates its flavors, making it an excellent method for creating tasty snacks and ingredients.

Types of Food Dehydrators

1. Home Food Dehydrators: These compact units are perfect for small-scale dehydration projects. They typically feature multiple trays and are ideal for drying fruits, vegetables, and herbs for personal use.

2. Commercial Air Dryers for Food: Designed for larger operations, these machines can handle greater volumes and are often used in restaurants, food processing facilities, and small businesses.

3. Industrial Food Drying Equipment: These are large-scale machines capable of processing vast quantities of food. They are commonly used in the food manufacturing industry and often incorporate advanced technologies for optimal efficiency.

The Science Behind Food Dehydration

The principle behind food dehydration is simple yet effective. By removing moisture from food, we create an environment that is inhospitable to bacteria, mold, and other microorganisms that cause spoilage. This process involves carefully controlling temperature, air flow, and humidity to achieve optimal results.

Hot Air Food Preservation

Hot air is the primary medium used in most food air drying machines. The temperature is typically set between 95°F to 165°F (35°C to 74°C), depending on the type of food being dried. This range is crucial as it's high enough to drive out moisture but low enough to preserve the food's nutritional content and enzymes.

Benefits of Using Food Air Drying Machines

1. Extended Shelf Life: Dehydrated foods can last for months or even years when stored properly.

2. Nutritional Preservation: Unlike some other preservation methods, dehydration retains most of the food's original nutrients.

3. Space-Saving: Dried foods take up less space than their fresh counterparts, making storage easier.

4. Flavor Enhancement: Dehydration concentrates flavors, often resulting in more intense and delicious tastes.

5. Versatility: From fruits and vegetables to meats and herbs, a wide variety of foods can be dehydrated.

Fruit and Vegetable Dehydration

Fruits and vegetables are among the most commonly dehydrated foods. The process not only preserves these nutritious foods but also creates delicious, healthy snacks.

Popular Fruits for Dehydration

- Apples

- Bananas

- Strawberries

- Mangoes

- Pineapples

Vegetables That Dehydrate Well

- Tomatoes

- Carrots

- Bell Peppers

- Onions

- Mushrooms

Energy-Efficient Food Drying

As sustainability becomes increasingly important, many manufacturers are focusing on developing energy-efficient food drying solutions. These machines are designed to maximize output while minimizing energy consumption, making them both environmentally friendly and cost-effective.

Features of Energy-Efficient Dehydrators

1. Improved Insulation: Better insulation helps maintain consistent temperatures with less energy input.

2. Smart Controls: Advanced control systems optimize energy use based on the specific requirements of each drying cycle.

3. Heat Recovery Systems: Some machines recycle heat, further reducing energy consumption.

4. LED Lighting: Energy-efficient LED lights are used for illumination and in some cases, to aid in the drying process.

Multi-Tray Food Dehydrators

Multi-tray food dehydrators are popular for both home and commercial use. These versatile machines allow for the simultaneous drying of different types of foods, maximizing efficiency and output.

Advantages of Multi-Tray Systems

1. Increased Capacity: Multiple trays allow for larger batches of food to be dried at once.

2. Flexibility: Different foods can be dried on separate trays, allowing for customized drying times and temperatures.

3. Easy Rotation: Trays can be rotated during the drying process to ensure even dehydration.

4. Expandability: Many models allow for additional trays to be added, increasing capacity as needed.

Stainless Steel Food Dryers

Stainless steel food dryers are preferred in many commercial and industrial settings due to their durability, ease of cleaning, and resistance to corrosion.

Benefits of Stainless Steel Construction

1. Hygiene: Stainless steel is non-porous and easy to sanitize, making it ideal for food processing equipment.

2. Durability: These machines can withstand heavy use and last for many years.

3. Temperature Stability: Stainless steel helps maintain consistent temperatures throughout the drying process.

4. Aesthetic Appeal: The sleek, professional look of stainless steel is often preferred in commercial kitchens and food processing facilities.

Food Drying Technology Advancements

The field of food drying is constantly evolving, with new technologies emerging to improve efficiency, quality, and versatility.

Recent Innovations

1. Microwave-Assisted Drying: This technology combines traditional hot air drying with microwave energy, significantly reducing drying times.

2. Ultrasound-Assisted Drying: The use of ultrasonic waves can enhance moisture removal and improve product quality.

3. Freeze-Drying: While not new, advancements in freeze-drying technology have made it more accessible for smaller-scale operations.

4. Smart Sensors: Advanced sensors and AI-driven controls optimize the drying process in real-time, ensuring consistent results.

Home Food Dehydration Techniques

While commercial and industrial food drying machines are impressive, there are also many techniques for home food dehydration that can yield excellent results.

Tips for Successful Home Dehydration

1. Proper Preparation: Wash and slice foods uniformly to ensure even drying.

2. Pre-treatment: Some foods benefit from blanching or dipping in lemon juice to preserve color and nutrients.

3. Temperature Control: Use the appropriate temperature for each food type to maintain quality and safety.

4. Air Circulation: Ensure good airflow around the food items for efficient drying.

5. Storage: Store dried foods in airtight containers in a cool, dark place to maximize shelf life.

Conclusion

Food air drying machines have revolutionized the way we preserve food, offering an efficient and effective method to extend shelf life while maintaining nutritional value and enhancing flavors. From small home units to large industrial equipment, these machines cater to a wide range of needs and applications. As technology continues to advance, we can expect even more innovative solutions in the field of food dehydration, further improving the quality and efficiency of this time-honored preservation technique.

Frequently Asked Questions

1. What are the best foods to dehydrate?

Answer: The best foods for dehydration include fruits like apples, bananas, and berries; vegetables such as tomatoes, carrots, and peppers; herbs; and lean meats for jerky. These foods have high water content and dehydrate well, retaining their flavor and nutritional value.

2. How long does the dehydration process typically take?

Answer: The dehydration time varies depending on the food type, its water content, and the dehydrator's efficiency. On average, fruits can take 6-12 hours, vegetables 4-8 hours, and meats for jerky 4-15 hours. Factors like slice thickness and desired final texture also affect drying time.

3. Are food dehydrators energy-efficient?

Answer: Modern food dehydrators are designed to be energy-efficient. They use less energy than ovens and can process large quantities of food at once. Energy consumption varies by model, but many units are comparable to running a light bulb, making them a cost-effective option for food preservation.

4. How do I clean and maintain my food dehydrator?

Answer: Clean your dehydrator after each use. Wash removable parts like trays and liners with warm, soapy water. Wipe down the interior with a damp cloth. For tough residues, use a mild detergent. Ensure all parts are completely dry before reassembling. Regular cleaning prevents flavor transfer and maintains hygiene.

5. Can I dehydrate different foods at the same time?

Answer: Yes, you can dehydrate different foods simultaneously, especially in multi-tray dehydrators. However, it's best to group foods with similar drying times and temperatures. Avoid mixing strongly flavored items with milder ones to prevent flavor transfer. Some dehydrators allow you to adjust tray positions for optimal results with different foods.