Content Menu

● Introduction to Commercial Fruit Dryer Machines

● The Technology Behind Commercial Fruit Dryer Machines

>> Types of Commercial Fruit Dryer Machines

● The Drying Process in Commercial Fruit Dryer Machines

>> Key Features of Advanced Commercial Fruit Dryer Machines

● Benefits of Using Commercial Fruit Dryer Machines

● Applications of Commercial Fruit Dryer Machines

● Choosing the Right Commercial Fruit Dryer Machine

● Future Trends in Commercial Fruit Dryer Machine Technology

● Conclusion

● Frequently Asked Questions about Commercial Fruit Dryer Machines

>> 1. Q: What types of fruits can be dried using commercial fruit dryer machines?

>> 2. Q: How long does it take to dry fruits in a commercial fruit dryer machine?

>> 3. Q: Are commercial fruit dryer machines energy-efficient?

>> 4. Q: How do commercial fruit dryer machines preserve the nutritional value of fruits?

>> 5. Q: Can commercial fruit dryer machines be used for other food products besides fruits?

Introduction to Commercial Fruit Dryer Machines

Commercial fruit dryer machines have become an indispensable part of the food processing industry, offering efficient and effective solutions for preserving fruits and vegetables. These advanced machines utilize cutting-edge technology to remove moisture from various produce, extending their shelf life while maintaining nutritional value and flavor. As the demand for dried fruits and vegetables continues to grow, the importance of commercial fruit dryer machines in the food industry cannot be overstated.

The Technology Behind Commercial Fruit Dryer Machines

Commercial fruit dryer machines employ sophisticated drying technologies to ensure optimal results. These machines typically use a combination of controlled heat, airflow, and sometimes vacuum or freeze-drying techniques to remove moisture from fruits and vegetables. The process is carefully monitored to maintain the desired temperature and humidity levels, ensuring that the produce is dried evenly and efficiently.

One of the key features of modern commercial fruit dryer machines is their ability to adjust drying parameters based on the specific requirements of different fruits and vegetables. This flexibility allows for the production of high-quality dried products with preserved nutritional content, color, and flavor.

Types of Commercial Fruit Dryer Machines

There are several types of commercial fruit dryer machines available in the market, each designed to cater to different production scales and specific drying needs:

1. Tunnel Dryers: These are continuous-flow dryers ideal for large-scale production.

2. Tray Dryers: Perfect for small to medium-scale operations, offering flexibility in batch processing.

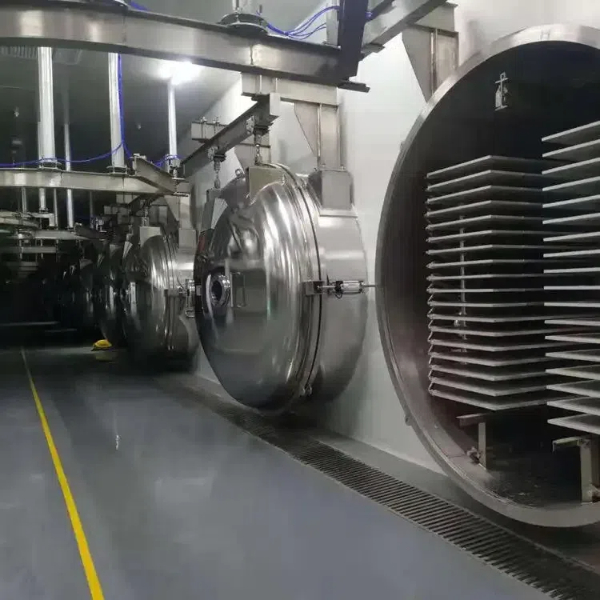

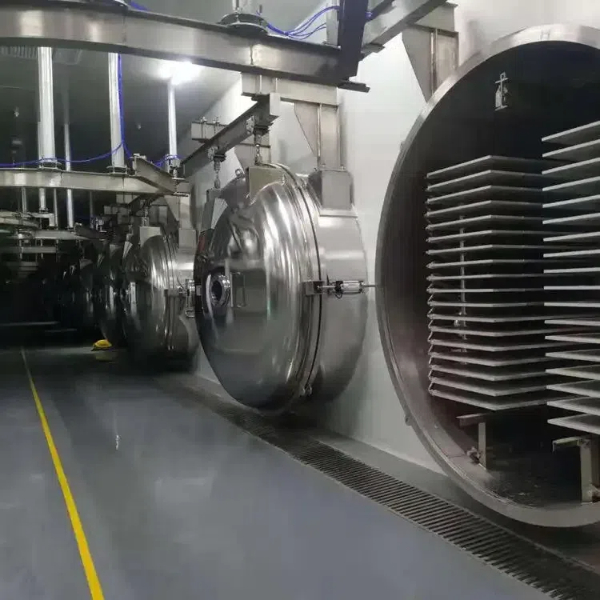

3. Freeze Dryers: Utilize sublimation to remove moisture, preserving the structure and nutrients of the fruit.

4. Vacuum Dryers: Operate at low temperatures, making them suitable for heat-sensitive fruits.

5. Heat Pump Dryers: Energy-efficient option that recirculates hot air for consistent drying.

The Drying Process in Commercial Fruit Dryer Machines

The drying process in commercial fruit dryer machines typically involves several stages:

1. Preparation: Fruits are washed, sorted, and sometimes pre-treated to enhance drying efficiency.

2. Loading: The prepared fruits are evenly distributed on trays or conveyor belts within the dryer.

3. Drying: Hot air circulates around the fruits, gradually removing moisture.

4. Monitoring: Sensors continuously track temperature, humidity, and moisture content.

5. Cooling: Once dried, the fruits are cooled to prevent condensation.

6. Packaging: The dried fruits are then packaged for storage or distribution.

Key Features of Advanced Commercial Fruit Dryer Machines

Modern commercial fruit dryer machines come equipped with a range of features designed to enhance efficiency and product quality:

- Precise temperature and humidity control

- Adjustable airflow systems

- Energy-efficient heat recovery mechanisms

- Automated loading and unloading systems

- Touch-screen interfaces for easy operation

- Remote monitoring and control capabilities

- Customizable drying programs for different fruits

Benefits of Using Commercial Fruit Dryer Machines

The adoption of commercial fruit dryer machines offers numerous benefits to food processors and consumers alike:

1. Extended Shelf Life: Dried fruits can be stored for months or even years without spoilage.

2. Preserved Nutritional Value: Proper drying techniques retain most of the fruit's original nutrients.

3. Reduced Storage and Transportation Costs: Dried fruits are lighter and occupy less space.

4. Year-round Availability: Seasonal fruits can be enjoyed throughout the year.

5. Versatility in Food Applications: Dried fruits are used in various food products and as standalone snacks.

6. Minimal Use of Preservatives: The drying process naturally preserves fruits without the need for additional chemicals.

7. Increased Profitability: Value-added dried fruit products often command higher prices in the market.

Applications of Commercial Fruit Dryer Machines

Commercial fruit dryer machines find applications across various sectors of the food industry:

- Snack Food Production: Creating healthy, on-the-go fruit snacks.

- Baking Industry: Providing dried fruits for use in breads, cakes, and pastries.

- Breakfast Cereal Manufacturing: Adding dried fruits to cereal mixes.

- Trail Mix and Granola Production: Incorporating a variety of dried fruits.

- Confectionery: Using dried fruits in chocolates and candies.

- Beverage Industry: Producing fruit powders for instant drinks and smoothies.

- Nutraceuticals: Creating fruit-based dietary supplements.

Choosing the Right Commercial Fruit Dryer Machine

When selecting a commercial fruit dryer machine, several factors should be considered:

1. Production Capacity: Ensure the machine can handle your required output.

2. Energy Efficiency: Look for models with heat recovery systems and efficient energy usage.

3. Versatility: Choose a machine capable of drying various types of fruits and vegetables.

4. Quality Control Features: Opt for machines with precise temperature and humidity controls.

5. Ease of Use: User-friendly interfaces and automated features can improve operational efficiency.

6. Maintenance Requirements: Consider the ease of cleaning and servicing the machine.

7. Compliance with Food Safety Standards: Ensure the machine meets all relevant industry regulations.

Future Trends in Commercial Fruit Dryer Machine Technology

The field of commercial fruit drying is continuously evolving, with several exciting trends on the horizon:

- Integration of Artificial Intelligence for optimized drying processes

- Development of hybrid drying technologies combining multiple drying methods

- Increased focus on sustainable and eco-friendly drying solutions

- Implementation of IoT for remote monitoring and predictive maintenance

- Advancements in non-thermal drying technologies to better preserve fruit qualities

Conclusion

Commercial fruit dryer machines have revolutionized the way we preserve and consume fruits. By offering efficient, consistent, and high-quality drying solutions, these machines have become essential in meeting the growing demand for dried fruit products. As technology continues to advance, we can expect even more innovative features and applications in the world of commercial fruit drying, further enhancing the industry's capabilities and the quality of dried fruit products available to consumers.

Frequently Asked Questions about Commercial Fruit Dryer Machines

1. Q: What types of fruits can be dried using commercial fruit dryer machines?

A: Commercial fruit dryer machines can process a wide variety of fruits, including apples, bananas, berries, mangoes, pineapples, and many more. The machines can be adjusted to accommodate the specific drying requirements of different fruits.

2. Q: How long does it take to dry fruits in a commercial fruit dryer machine?

A: The drying time varies depending on the type of fruit, its moisture content, and the desired final product. It can range from a few hours for thin-sliced fruits to 24-48 hours for larger, juicier fruits. The machine's settings can be optimized for each fruit type to ensure efficient drying.

3. Q: Are commercial fruit dryer machines energy-efficient?

A: Many modern commercial fruit dryer machines are designed with energy efficiency in mind. They often incorporate features like heat recovery systems, insulation, and precise controls to minimize energy consumption. Some models, such as heat pump dryers, are particularly known for their energy efficiency.

4. Q: How do commercial fruit dryer machines preserve the nutritional value of fruits?

A: Commercial fruit dryer machines use controlled temperatures and airflow to remove moisture without damaging the fruit's cellular structure. This process helps retain most of the fruit's original nutrients, vitamins, and minerals. Some advanced machines also use low-temperature drying techniques to further preserve heat-sensitive nutrients.

5. Q: Can commercial fruit dryer machines be used for other food products besides fruits?

A: Yes, many commercial fruit dryer machines are versatile and can be used to dry a variety of food products, including vegetables, herbs, meats, and even some dairy products. The machines' settings can be adjusted to accommodate the drying requirements of different food items.