Content Menu

● Introduction

● Understanding Food Dryers

● The Cost of Heat Pump Dryers

● Comparing Costs: Heat Pump vs. Gas and Electric Models

>> Initial Investment

>> Operational Costs

>> Maintenance Costs

● Benefits of Heat Pump Technology in Food Drying

>> Energy Efficiency

>> Quality Preservation

>> Versatility

>> Environmentally Friendly

>> Consistent Results

● Case Studies: Successful Implementation of Heat Pump Dryers

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer for food?

>> 2. How does the drying process differ between heat pump and gas dryers?

>> 3. Are heat pump dryers suitable for all types of food?

>> 4. What maintenance is required for heat pump dryers?

>> 5. Can heat pump dryers help reduce environmental impact?

Introduction

In the world of food processing, drying is a crucial step that significantly affects the quality, shelf life, and marketability of food products. As a leading manufacturer of food dryers in China, we specialize in providing OEM services to international brands, wholesalers, and producers. This article will explore the various types of food dryers, focusing on heat pump dryers, and how their costs compare to gas and electric models. We will also delve into the benefits of using heat pump technology in food drying, the operational efficiencies, and the long-term savings associated with these systems.

Understanding Food Dryers

Food dryers are essential equipment in the food industry, used to remove moisture from food products to prevent spoilage and extend shelf life. There are several types of food dryers, including:

1. Conventional Dryers: These use direct heat sources, such as gas or electric heating elements, to dry food. They are often less energy-efficient and can lead to uneven drying.

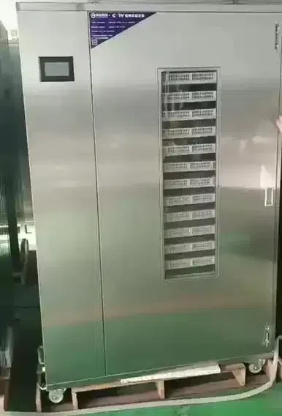

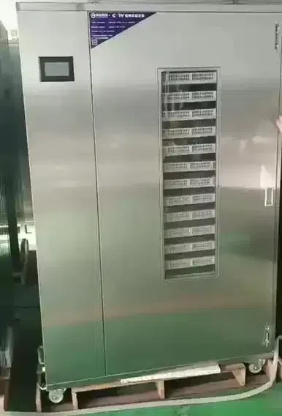

2. Heat Pump Dryers: These utilize heat pump technology to extract moisture from food while maintaining a consistent temperature. They are known for their energy efficiency and ability to preserve the quality of the food.

3. Solar Dryers: These rely on solar energy to dry food, making them environmentally friendly but dependent on weather conditions.

4. Microwave Dryers: These use microwave radiation to heat and evaporate moisture quickly. They are suitable for specific applications but can be costly.

The Cost of Heat Pump Dryers

Heat pump dryers are becoming increasingly popular in the food processing industry due to their energy efficiency and ability to maintain the nutritional quality of food. The initial investment for a heat pump dryer can be higher than that of gas or electric models. However, the long-term savings on energy costs and the benefits of better product quality often outweigh the initial expenditure.

Comparing Costs: Heat Pump vs. Gas and Electric Models

Initial Investment

Heat pump dryers typically have a higher upfront cost compared to gas and electric models. This is due to the advanced technology and components involved in their design. Gas dryers may have a lower initial cost but can incur higher operational costs depending on gas prices. Electric dryers are generally less expensive to purchase but can lead to higher electricity bills, especially in regions with high energy costs.

Operational Costs

Heat pump dryers are known for their low operational costs. They use less energy to operate, which can lead to significant savings over time. Gas dryers can be economical in terms of energy consumption, but fluctuating gas prices can affect overall costs. Electric dryers often have higher energy consumption rates, leading to increased electricity bills.

Maintenance Costs

Heat pump dryers require regular maintenance to ensure optimal performance, but their durability often results in lower long-term maintenance costs. Gas dryers may require more frequent servicing due to the combustion process and potential issues with gas lines. Electric dryers generally have fewer mechanical parts, which can lead to lower maintenance costs.

Benefits of Heat Pump Technology in Food Drying

Energy Efficiency

Heat pump dryers are designed to recycle heat, making them significantly more energy-efficient than traditional gas or electric dryers. This efficiency translates into lower energy bills and a reduced carbon footprint. By utilizing ambient air and converting it into usable heat, heat pump dryers can operate at a fraction of the energy cost of conventional dryers.

Quality Preservation

The gentle drying process of heat pump dryers helps preserve the nutritional value, color, and flavor of food products. This is particularly important for fruits, vegetables, and herbs, where quality is paramount. Unlike conventional dryers that can cause food to lose moisture too quickly, heat pump dryers maintain a stable temperature, ensuring that the food retains its essential nutrients and appealing appearance.

Versatility

Heat pump dryers can be used for a wide range of food products, from fruits and vegetables to meats and fish. Their adjustable settings allow for precise control over drying conditions. This versatility makes them suitable for various applications, including commercial food processing, small-scale operations, and even home use.

Environmentally Friendly

By using less energy and reducing waste, heat pump dryers are a more sustainable option for food processing. They contribute to a greener food industry by minimizing environmental impact. The ability to operate efficiently at lower temperatures also means that heat pump dryers can be powered by renewable energy sources, further enhancing their eco-friendliness.

Consistent Results

The technology used in heat pump dryers ensures uniform drying, reducing the risk of over-drying or under-drying food products. This consistency is crucial for maintaining product quality. With advanced sensors and controls, heat pump dryers can automatically adjust drying times and temperatures based on the moisture content of the food, ensuring optimal results every time.

Case Studies: Successful Implementation of Heat Pump Dryers

Several food processing companies have successfully integrated heat pump dryers into their operations, resulting in improved efficiency and product quality. For instance, a fruit processing company reported a 30% reduction in energy costs after switching to heat pump technology. Additionally, they noted an increase in the shelf life of their dried products, leading to higher customer satisfaction and repeat business.

Another case involved a vegetable processing plant that struggled with inconsistent drying results using conventional methods. After implementing heat pump dryers, they achieved uniform drying across all batches, significantly reducing waste and improving product quality. The plant manager reported that the investment in heat pump technology paid off within two years due to the savings on energy and increased sales from higher-quality products.

Conclusion

In conclusion, while heat pump dryers may have a higher initial cost compared to gas and electric models, their energy efficiency, quality preservation, and long-term savings make them a worthwhile investment for food processing companies. As the demand for high-quality dried food products continues to grow, adopting advanced drying technologies like heat pumps will be essential for staying competitive in the market.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer for food?

The main advantage is energy efficiency, which leads to lower operational costs and better preservation of food quality.

2. How does the drying process differ between heat pump and gas dryers?

Heat pump dryers use a gentle, low-temperature drying process, while gas dryers use direct heat, which can lead to uneven drying and potential quality loss.

3. Are heat pump dryers suitable for all types of food?

Yes, heat pump dryers are versatile and can be used for a wide range of food products, including fruits, vegetables, meats, and herbs.

4. What maintenance is required for heat pump dryers?

Regular maintenance includes cleaning filters, checking refrigerant levels, and ensuring that all components are functioning properly.

5. Can heat pump dryers help reduce environmental impact?

Yes, by using less energy and minimizing waste, heat pump dryers contribute to a more sustainable food processing industry.