Content Menu

● Understanding Heat Pump Dryers

>> Benefits of Using Heat Pump Dryers for Food

● Key Features to Consider

>> Capacity

>> Temperature Control

>> Humidity Control

>> Energy Efficiency Rating

>> Ease of Use

>> Maintenance Requirements

>> Safety Features

● Choosing the Right Manufacturer

>> Experience and Reputation

>> OEM Services

>> Technical Support

>> Warranty and Service Agreements

>> Compliance with Standards

● Installation and Operation

>> Professional Installation

>> Training for Staff

>> Regular Monitoring

>> Cleaning and Maintenance

● Types of Food Suitable for Heat Pump Drying

>> Fruits

>> Vegetables

>> Herbs

>> Meats

>> Flowers and Edible Plants

● Cost Considerations

>> Initial Investment

>> Operating Costs

>> Maintenance Expenses

>> Return on Investment

● Conclusion

● Frequently Asked Questions

>> 1. What types of food can be dried using a heat pump dryer?

>> 2. How does a heat pump dryer differ from a conventional dryer?

>> 3. What is the average lifespan of a heat pump dryer?

>> 4. Are heat pump dryers energy-efficient?

>> 5. Can I customize a heat pump dryer for my specific needs?

When it comes to food preservation, drying is one of the most effective methods. Food drying not only extends the shelf life of products but also retains their nutritional value and flavor. In recent years, heat pump dryers have gained popularity in the food processing industry due to their energy efficiency and ability to maintain product quality. This article will guide you through the process of choosing the best value heat pump dryer for your needs, focusing on the specific requirements of food drying.

Understanding Heat Pump Dryers

Heat pump dryers operate on a simple principle: they use a refrigeration cycle to extract moisture from food products. Unlike traditional dryers that rely on direct heat, heat pump dryers circulate warm air, which is then cooled and dehumidified. This process allows for lower drying temperatures, which is crucial for preserving the quality of sensitive food items.

Benefits of Using Heat Pump Dryers for Food

1. Energy Efficiency: Heat pump dryers consume significantly less energy compared to conventional drying methods. This is particularly important for businesses looking to reduce operational costs.

2. Quality Preservation: The lower drying temperatures help maintain the nutritional content, color, and flavor of the food. This is especially beneficial for fruits, vegetables, and herbs.

3. Versatility: Heat pump dryers can handle a wide range of food products, from fruits and vegetables to meats and fish. This versatility makes them an excellent choice for food manufacturers.

4. Environmentally Friendly: By using less energy and producing less waste heat, heat pump dryers are a more sustainable option for food processing.

5. Consistent Results: These dryers provide uniform drying, reducing the risk of over-drying or under-drying, which can affect product quality.

Key Features to Consider

When selecting a heat pump dryer for food processing, several key features should be taken into account:

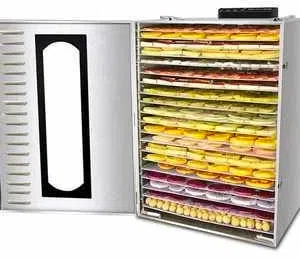

Capacity

The capacity of the dryer is crucial, especially for commercial operations. Consider the volume of food you plan to dry and choose a model that can handle your production needs. Larger capacities may be more suitable for bulk processing, while smaller units can be ideal for artisanal producers.

Temperature Control

Look for a dryer with precise temperature control settings. The ability to adjust the temperature is essential for different types of food. For instance, delicate fruits may require lower temperatures, while meats may need higher settings.

Humidity Control

Effective humidity control is vital for achieving optimal drying results. A good heat pump dryer should have the capability to monitor and adjust humidity levels throughout the drying process.

Energy Efficiency Rating

Check the energy efficiency rating of the dryer. Higher efficiency ratings indicate lower energy consumption, which can lead to significant cost savings over time.

Ease of Use

Consider the user-friendliness of the dryer. Features such as digital controls, programmable settings, and easy-to-read displays can enhance the user experience and streamline operations.

Maintenance Requirements

Regular maintenance is essential for the longevity of any equipment. Choose a dryer that is easy to clean and maintain, with accessible components for servicing.

Safety Features

Safety should always be a priority. Look for dryers with built-in safety features such as overheat protection, automatic shut-off, and alarms for malfunctioning components.

Choosing the Right Manufacturer

Selecting the right manufacturer for your heat pump dryer is just as important as choosing the right model. Here are some tips for finding a reliable supplier:

Experience and Reputation

Look for manufacturers with a proven track record in the food processing industry. Research their reputation and read customer reviews to gauge their reliability.

OEM Services

As a factory providing OEM services, ensure that the manufacturer can customize the dryer to meet your specific needs. This includes branding, design modifications, and tailored features.

Technical Support

Choose a manufacturer that offers comprehensive technical support. This can be invaluable for troubleshooting and maintenance, ensuring minimal downtime for your operations.

Warranty and Service Agreements

Inquire about warranty options and service agreements. A good warranty can provide peace of mind and protect your investment.

Compliance with Standards

Ensure that the manufacturer complies with relevant industry standards and regulations. This is particularly important for food safety and quality assurance.

Installation and Operation

Once you have selected the right heat pump dryer, proper installation and operation are crucial for optimal performance. Here are some tips:

Professional Installation

Consider hiring professionals for installation to ensure that the dryer is set up correctly. This can prevent issues down the line and ensure compliance with safety standards.

Training for Staff

Provide training for your staff on how to operate the dryer effectively. This includes understanding the controls, monitoring the drying process, and performing routine maintenance.

Regular Monitoring

Regularly monitor the drying process to ensure that the desired moisture content is achieved. Adjust settings as necessary based on the type of food being dried.

Cleaning and Maintenance

Establish a cleaning and maintenance schedule to keep the dryer in optimal condition. This includes cleaning filters, checking for blockages, and inspecting components for wear and tear.

Types of Food Suitable for Heat Pump Drying

Heat pump dryers are versatile and can be used for a variety of food products. Here are some common types of food that can be effectively dried using heat pump technology:

Fruits

Fruits such as apples, bananas, and berries are popular choices for drying. The low temperatures of heat pump dryers help retain their natural sugars and flavors, resulting in delicious dried fruit snacks.

Vegetables

Vegetables like carrots, tomatoes, and bell peppers can also be dried using heat pump dryers. This method preserves their color and nutritional value, making them ideal for soups, stews, and snacks.

Herbs

Herbs such as basil, oregano, and thyme can be dried to enhance their flavor and aroma. Heat pump dryers provide a gentle drying process that maintains the essential oils in herbs.

Meats

Meat products, including jerky and dried fish, can be effectively dried using heat pump technology. The controlled environment helps prevent spoilage and ensures food safety.

Flowers and Edible Plants

In addition to food, heat pump dryers can be used to dry flowers and edible plants for culinary and decorative purposes. This adds versatility to the drying process.

Cost Considerations

When investing in a heat pump dryer, it’s essential to consider the overall cost, including initial purchase price, installation, and ongoing operational expenses. Here are some factors to keep in mind:

Initial Investment

Heat pump dryers can have a higher upfront cost compared to traditional dryers. However, the long-term savings on energy bills and improved product quality can offset this initial investment.

Operating Costs

Consider the energy consumption of the dryer and how it will impact your monthly utility bills. Look for models with high energy efficiency ratings to minimize operating costs.

Maintenance Expenses

Regular maintenance is necessary to keep the dryer running efficiently. Factor in the costs of routine maintenance and any potential repairs when budgeting for your dryer.

Return on Investment

Evaluate the potential return on investment (ROI) based on your production needs and the quality of the dried products. A high-quality heat pump dryer can lead to increased sales and customer satisfaction.

Conclusion

Choosing the best value heat pump dryer for your food processing needs involves careful consideration of various factors, including capacity, temperature control, energy efficiency, and manufacturer reliability. By investing in a high-quality heat pump dryer, you can enhance your food preservation processes, reduce energy costs, and maintain the quality of your products.

Frequently Asked Questions

1. What types of food can be dried using a heat pump dryer?

Heat pump dryers can be used for a variety of foods, including fruits, vegetables, meats, and herbs.

2. How does a heat pump dryer differ from a conventional dryer?

Heat pump dryers use a refrigeration cycle to extract moisture at lower temperatures, while conventional dryers rely on direct heat.

3. What is the average lifespan of a heat pump dryer?

With proper maintenance, a heat pump dryer can last anywhere from 10 to 15 years.

4. Are heat pump dryers energy-efficient?

Yes, heat pump dryers are known for their energy efficiency, often using significantly less energy than traditional drying methods.

5. Can I customize a heat pump dryer for my specific needs?

Many manufacturers offer OEM services, allowing you to customize the dryer to meet your specific requirements.