Content Menu

● Introduction

● Understanding Food Drying Machines

● Maintenance Costs Overview

>> 1. Condenser Dryers

>> 2. Heat Pump Dryers

● Factors Influencing Maintenance Costs

● Comparing Performance and Efficiency

>> Performance

>> Efficiency

● Conclusion

● Frequently Asked Questions

>> 1. What is the main difference between condenser and heat pump dryers?

>> 2. Which type of dryer is more energy-efficient?

>> 3. How often should I clean my food drying machine?

>> 4. What are the common maintenance tasks for food dryers?

>> 5. Can I use a heat pump dryer for all types of food?

Introduction

In the world of food processing, drying is a crucial step that significantly affects the quality, shelf life, and safety of food products. As a leading manufacturer of food drying machines in China, we provide OEM services to international brands, wholesalers, and producers. This article will explore the maintenance costs associated with two popular types of dryers: condenser dryers and heat pump dryers. While our focus is on food drying machines, understanding these concepts can help businesses make informed decisions about their equipment.

Understanding Food Drying Machines

Food drying machines are designed to remove moisture from food products, thereby inhibiting the growth of bacteria, yeast, and mold. This process not only preserves the food but also enhances its flavor and nutritional value. There are various types of food drying machines, including:

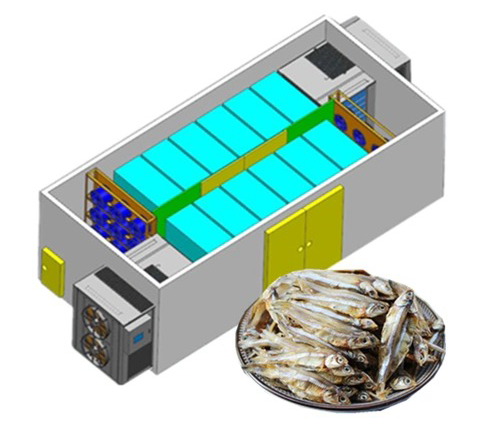

1. Condenser Dryers: These machines use a heating element to warm the air, which is then circulated through the food. The moisture in the food evaporates and is condensed back into water, which is collected in a tank or drained away.

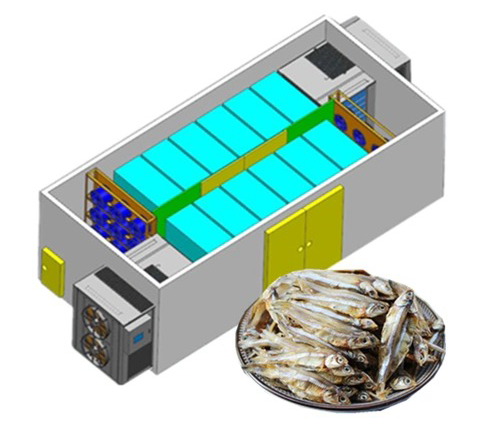

2. Heat Pump Dryers: These dryers utilize heat pump technology to recycle heat within the system. They operate at lower temperatures, making them more energy-efficient and suitable for delicate food items.

Maintenance Costs Overview

When considering the purchase of a food drying machine, maintenance costs are a critical factor. These costs can vary significantly between condenser and heat pump dryers due to their different operating mechanisms and components.

1. Condenser Dryers

Condenser dryers are generally easier to maintain. However, they do have specific maintenance requirements that can incur costs:

1. Cleaning the Condenser: The condenser unit needs regular cleaning to ensure efficient operation. Dust and debris can accumulate, reducing the machine's efficiency and increasing energy consumption.

2. Water Tank Maintenance: If the machine collects water in a tank, this tank must be emptied regularly. Failure to do so can lead to overflow issues and potential damage to the machine.

3. Heating Element Replacement: Over time, the heating element may wear out and require replacement. This can be a significant cost depending on the model.

4. Energy Costs: While not a direct maintenance cost, condenser dryers typically consume more energy than heat pump dryers, leading to higher operational costs over time.

2. Heat Pump Dryers

Heat pump dryers, while more energy-efficient, come with their own set of maintenance considerations:

1. Complexity of Components: Heat pump dryers have more complex components, including the heat exchanger and compressor. These parts may require specialized maintenance, which can be more expensive.

2. Regular Servicing: To maintain optimal performance, heat pump dryers should be serviced regularly by professionals. This can include checking refrigerant levels and ensuring that the heat exchanger is clean.

3. Cost of Repairs: If a heat pump dryer malfunctions, repairs can be more costly due to the complexity of the system. Parts may also be more expensive compared to those for condenser dryers.

4. Energy Efficiency Savings: Despite potentially higher maintenance costs, heat pump dryers can save money in the long run due to their lower energy consumption. This can offset some of the maintenance expenses.

Factors Influencing Maintenance Costs

Several factors can influence the maintenance costs of food drying machines, including:

1. Frequency of Use: Machines that are used more frequently will require more maintenance. Understanding the expected usage can help in budgeting for maintenance costs.

2. Type of Food Being Dried: Different foods may produce varying amounts of residue and moisture, affecting how often the machine needs cleaning and servicing.

3. Quality of the Machine: Higher-quality machines may have lower maintenance costs due to better construction and materials. Investing in a reputable brand can lead to long-term savings.

4. Environmental Conditions: The environment in which the dryer operates can also impact maintenance needs. For example, a dusty or humid environment may require more frequent cleaning.

Comparing Performance and Efficiency

When evaluating the overall costs associated with food drying machines, it is essential to consider not only maintenance but also performance and efficiency.

Performance

1. Drying Speed: Condenser dryers typically operate at higher temperatures, which can lead to faster drying times. This is beneficial for businesses that require quick turnaround times for their products. However, the higher temperatures can also affect the quality of more delicate foods, potentially leading to nutrient loss or changes in texture.

2. Energy Consumption: Heat pump dryers, on the other hand, operate at lower temperatures, which can take longer to dry food. However, this method is gentler on the food and helps preserve its quality. The energy savings from using a heat pump dryer can be significant, especially for businesses that operate on a large scale.

Efficiency

1. Energy Efficiency Ratings: When comparing dryers, it is crucial to look at their energy efficiency ratings. Heat pump dryers generally have higher ratings, meaning they use less energy to achieve the same results as condenser dryers. This can lead to substantial savings on energy bills over time.

2. Long-Term Cost Analysis: While the initial purchase price of heat pump dryers may be higher, the long-term savings on energy and maintenance can make them a more cost-effective option in the long run. Businesses should conduct a thorough cost analysis to determine which type of dryer will be more economical based on their specific needs.

Conclusion

When choosing between condenser and heat pump dryers for food processing, it is essential to consider not only the initial purchase price but also the long-term maintenance costs. While condenser dryers may have lower upfront maintenance requirements, heat pump dryers offer energy efficiency that can lead to savings over time. Ultimately, the best choice will depend on the specific needs of your food processing operation.

Frequently Asked Questions

1. What is the main difference between condenser and heat pump dryers?

The main difference lies in their operation; condenser dryers use a heating element to dry food, while heat pump dryers recycle heat, making them more energy-efficient.

2. Which type of dryer is more energy-efficient?

Heat pump dryers are generally more energy-efficient than condenser dryers, leading to lower operational costs.

3. How often should I clean my food drying machine?

It is recommended to clean your machine after every use to maintain efficiency and prevent buildup of residue.

4. What are the common maintenance tasks for food dryers?

Common tasks include cleaning the condenser, emptying water tanks, and checking heating elements or compressors.

5. Can I use a heat pump dryer for all types of food?

Yes, heat pump dryers are versatile and can be used for various food types, but they are particularly suitable for delicate items due to their lower drying temperatures.