Content Menu

● Understanding Heat Pump Dryers

>> How Heat Pump Dryers Work

● Calculating the Cost of Running a Heat Pump Dryer

>> Formula for Calculation

● Factors Influencing Running Costs

● Advantages of Using Heat Pump Dryers

● Common Applications of Heat Pump Dryers

● Maintenance Tips for Heat Pump Dryers

● Conclusion

● FAQ

>> 1. What is a heat pump dryer?

>> 2. How much does it cost to run a heat pump dryer?

>> 3. Can I use a heat pump dryer for all types of food?

>> 4. Are heat pump dryers environmentally friendly?

>> 5. How long does it take to dry food using a heat pump dryer?

● Citations:

Food drying is an essential process in food preservation, allowing for the storage of fruits, vegetables, and meats without the need for refrigeration. In recent years, heat pump dryers have emerged as a popular choice for both industrial and home use due to their energy efficiency and effectiveness. This article will delve into the mechanics of heat pump dryers, how to calculate their running costs, and provide insights into their advantages over traditional drying methods.

Understanding Heat Pump Dryers

Heat pump dryers operate using a closed-loop system that recycles air, making them significantly more energy-efficient than conventional dryers. Unlike traditional dryers that expel hot air and require constant heating elements, heat pump dryers utilize a refrigerant system to absorb moisture from the air inside the dryer.

How Heat Pump Dryers Work

1. Air Intake: Ambient air is drawn into the dryer.

2. Heating: The air passes through a heat exchanger where it is heated.

3. Drying: The warm air is circulated through the drying chamber where it absorbs moisture from the food.

4. Moisture Removal: The humid air is then cycled back through another heat exchanger where moisture is removed.

5. Recycling: The now-dry air is reheated and returned to the drying chamber.

This process not only minimizes energy consumption but also preserves the nutritional quality of the food being dried.

Calculating the Cost of Running a Heat Pump Dryer

To determine the cost of running a heat pump dryer, you need to consider several factors:

- Wattage of the Dryer: This is usually indicated on the appliance itself or in its manual.

- Hours of Operation: How long you intend to run the dryer each day.

- Cost per Kilowatt-Hour (kWh): This varies by region and can be found on your electricity bill.

Formula for Calculation

The following formula can be used to calculate your running costs:

Cost =(Wattage x Hours/1000) x Cost per kWh

For instance, if your heat pump dryer has a wattage of 600 watts and you use it for 12 hours at an electricity cost of $0.15 per kWh:

1. Calculate kWh used:

600 watts x 12 hours/1000 = 7.2 kWh

2. Calculate cost:

7.2 kWh x 0.15 = $1.08

Thus, running this dryer for 12 hours would cost approximately $1.08.

Factors Influencing Running Costs

While calculating the cost is straightforward, several factors can influence the overall expenses associated with operating a heat pump dryer:

- Type of Food Being Dried: Different foods have varying moisture content and drying times. For example, fruits may take longer than vegetables due to higher sugar content.

- Initial Moisture Content: The more moisture present in the food, the longer it will take to dry, thus increasing energy consumption.

- Ambient Temperature and Humidity: Higher humidity levels can affect drying efficiency, potentially leading to longer drying times and increased energy costs.

- Load Size: A fully loaded dryer may take longer to dry than a partially filled one. However, overloading can also lead to inefficient drying.

Advantages of Using Heat Pump Dryers

Heat pump dryers offer several benefits over traditional drying methods:

- Energy Efficiency: They consume significantly less energy—up to 50% less than conventional dryers—due to their recycling mechanism.

- Lower Operating Costs: As illustrated in previous calculations, their operating costs are lower, making them more economical in the long run.

- Preservation of Nutritional Value: The low-temperature drying process helps retain vitamins and minerals in food products.

- Versatility: Suitable for a variety of food types including fruits, vegetables, meats, and herbs.

- Environmentally Friendly: By reducing energy consumption and emissions, they contribute to a more sustainable practice in food processing.

Common Applications of Heat Pump Dryers

Heat pump dryers are versatile and can be used in various applications:

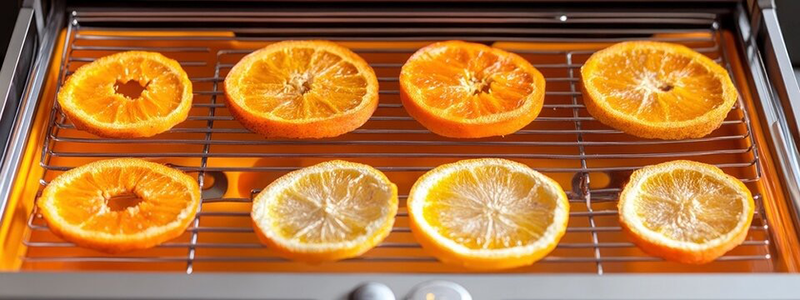

- Fruit Drying: Apples, bananas, mangoes, etc., can be effectively dried while retaining flavor and nutrients.

- Vegetable Drying: Carrots, spinach, peppers, etc., are commonly dried for long-term storage or snack production.

- Meat Drying: Jerky production from beef or poultry benefits from controlled temperature settings that prevent spoilage while enhancing flavor.

- Herbs and Spices: Retaining aromatic properties while reducing moisture content allows for better flavor profiles in culinary applications.

Maintenance Tips for Heat Pump Dryers

To ensure your heat pump dryer operates efficiently over time, regular maintenance is crucial:

- Clean Filters Regularly: Dust and lint can accumulate in filters and reduce airflow efficiency. Cleaning them every few weeks can enhance performance.

- Check Seals and Insulation: Ensure that door seals are intact to prevent heat loss during operation. Damaged seals should be replaced promptly.

- Regularly Inspect Components: Periodically check components such as fans and compressors for any signs of wear or malfunctioning parts.

- Keep the Dryer Clean: Wipe down surfaces inside and outside regularly to prevent buildup that could affect performance.

Conclusion

Heat pump dryers represent a modern solution for food preservation that balances efficiency with effectiveness. Understanding how to calculate their running costs can help users make informed decisions about their energy consumption and overall expenses.

By investing in heat pump technology, businesses can not only save money but also enhance the quality of their dried products while contributing positively to environmental sustainability. As consumers increasingly demand healthier options with minimal environmental impact, adopting heat pump dryers may become an essential strategy for food producers looking to stay competitive in today's market.

FAQ

1. What is a heat pump dryer?

A heat pump dryer is an appliance that uses a closed-loop system to recycle air for drying clothes or food products efficiently without needing constant heating elements.

2. How much does it cost to run a heat pump dryer?

The cost depends on its wattage, hours of operation, and local electricity rates. For example, running a 600-watt dryer for 12 hours may cost around $1.08 at $0.15 per kWh.

3. Can I use a heat pump dryer for all types of food?

Yes! Heat pump dryers are versatile and can effectively dry fruits, vegetables, meats, herbs, and spices.

4. Are heat pump dryers environmentally friendly?

Yes! They consume less energy compared to traditional dryers and reduce greenhouse gas emissions associated with electricity generation.

5. How long does it take to dry food using a heat pump dryer?

Drying times vary based on the type of food but typically range from 4 to 8 hours depending on moisture content and thickness of slices.

Citations:

[1] https://hugoenergyapp.co.uk/how-much-does-a-tumble-dryer-cost-to-run-and-how-can-you-make-it-cheaper/

[2] https://aradmachineryco.com/article/How-to-make-a-food-dehydrator

[3] https://www.dryitcanit.com/post/the-lowdown-on-the-cost-of-running-a-food-dehydrator

[4] https://www.alamy.com/stock-photo/food-dehydrator.html

[5] https://www.ike.cn/video.html

[6] https://www.youtube.com/watch?v=DeN-h6opueM

[7] https://www.bxdrymachine.com/food-drying-machine.html

[8] https://dehydratorreview.net/articles/how-much-does-it-cost-dehydrate-food

[9] https://www.youtube.com/watch?v=1fP2rSLjys4

[10] https://www.youtube.com/watch?v=S-hDpODzIV0