Content Menu

● Introduction to Fish Dehydration Machines

>> Working Principle

● Components of a Fish Dehydration Machine

● Benefits of Using a Fish Dehydration Machine

● Applications of Fish Dehydration Machines

● Preparing Fish for Dehydration

● Setting Up the Machine

● Maintenance and Troubleshooting

● Energy Efficiency and Environmental Impact

● Conclusion

● FAQs

>> 1. What is the typical temperature range for drying fish in a fish dehydration machine?

>> 2. How does a fish dehydration machine preserve nutrients?

>> 3. What are the advantages of using a heat pump fish dehydration machine?

>> 4. Can a fish dehydration machine be used for other foods?

>> 5. How do you ensure uniform drying in a fish dehydration machine?

● Citations:

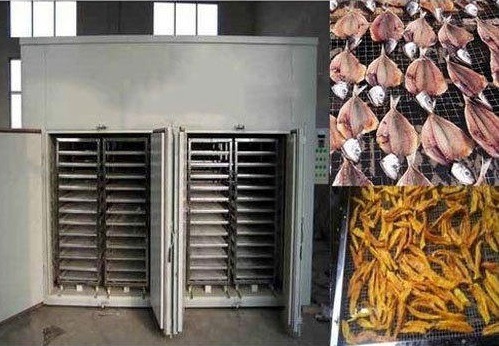

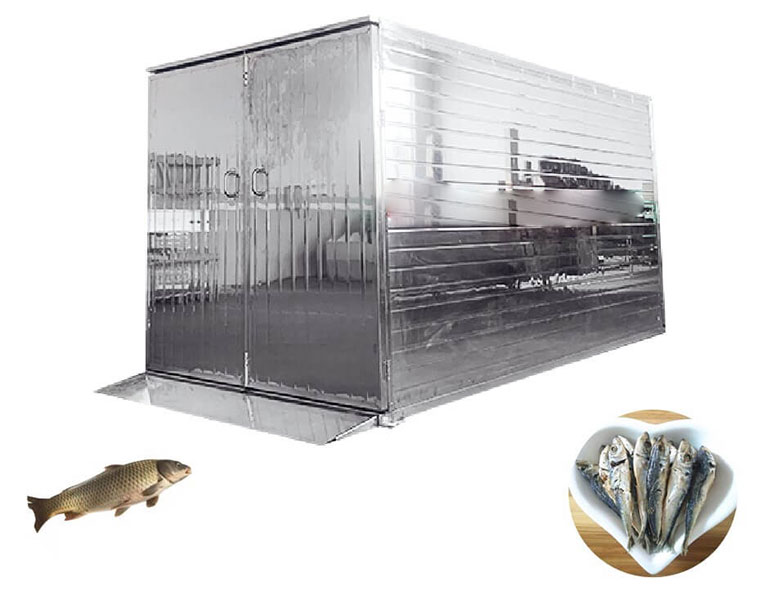

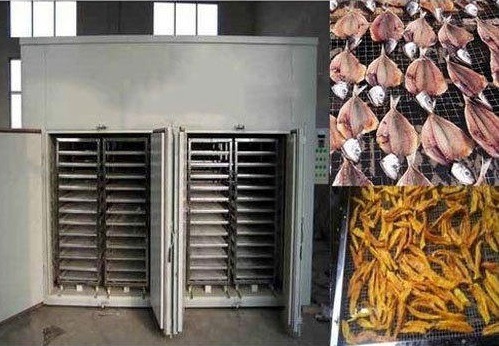

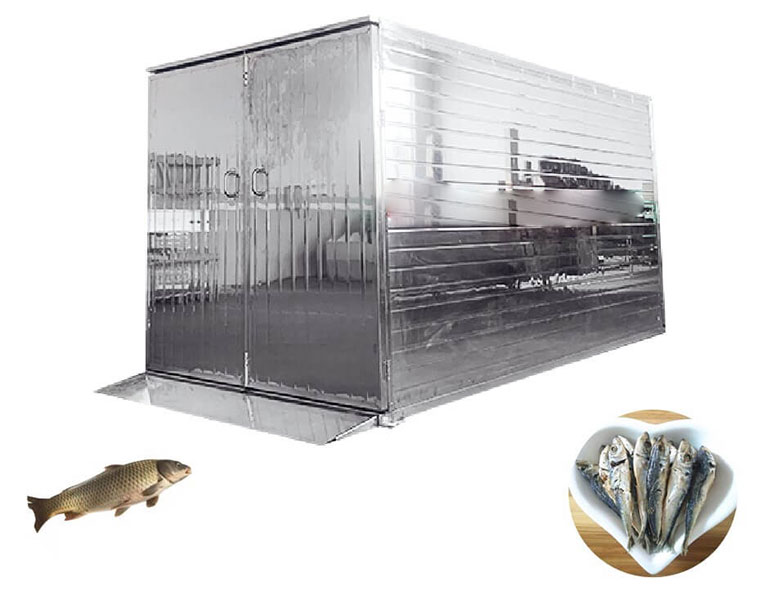

Fish dehydration machines are specialized equipment designed to remove moisture from fish, extending their shelf life and preserving their nutritional value. These machines are crucial in the seafood processing industry, offering a more efficient and consistent drying process compared to traditional methods. In this article, we will delve into the working principle of fish dehydration machines, their benefits, and how they are used in the industry.

Introduction to Fish Dehydration Machines

Fish dehydration machines, also known as fish dehydrators or fish dryers, utilize controlled heat and airflow to accelerate the drying process. This technology ensures that the fish is dried evenly, maintaining its texture and flavor while reducing the risk of spoilage.

Working Principle

The working principle of a fish dehydration machine involves several key components:

1. Heating System: The machine uses electric heating bars or gas burners to generate heat.

2. Air Circulation: Efficient fans distribute the hot air evenly throughout the drying chamber, ensuring uniform drying.

3. Temperature Control: Adjustable temperature settings allow operators to optimize the drying conditions for different fish varieties.

4. Humidity Control: Some machines incorporate dehumidification systems to maintain optimal humidity levels, enhancing the drying efficiency.

Components of a Fish Dehydration Machine

A typical fish dehydration machine includes:

- Controller: A system control panel for setting temperature, humidity, and operating modes.

- Power Jack: For connecting the machine to a power source.

- Water Outlet: For draining condensed moisture.

- Supporting Racks and Trays: For holding the fish during the drying process.

- Circulating Air Inlet and Outlet: For managing airflow within the machine.

Benefits of Using a Fish Dehydration Machine

Using a fish dehydration machine offers several advantages:

- Increased Shelf-Life: Removes moisture, reducing bacterial growth and spoilage.

- Improved Nutrition: Preserves essential nutrients like omega-3 fatty acids.

- Versatility: Dried fish can be used in various recipes or as animal feed.

- Efficiency: Faster and more consistent drying compared to traditional methods.

- Cost-Effective: Reduces labor and time required for drying.

Applications of Fish Dehydration Machines

Fish dehydration machines are widely used in the seafood processing industry for drying various types of fish. They are also suitable for small-scale operations, such as drying experiments and scientific research.

Preparing Fish for Dehydration

Before using a fish dehydration machine, it is essential to prepare the fish properly:

1. Choose Fresh Fish: Ensure the fish is of high quality.

2. Cleaning and Filleting: Remove scales, guts, and fins, and fillet the fish into uniform pieces.

3. Seasoning (Optional): Marinate the fish for enhanced flavor.

Setting Up the Machine

1. Load the Fish: Place the prepared fish on the trays.

2. Set Parameters: Adjust the temperature and drying time according to the fish type and thickness.

3. Monitor the Process: Periodically check the fish's dryness.

Maintenance and Troubleshooting

Regular maintenance is crucial to ensure the longevity and efficiency of the machine:

- Cleanliness: Regularly clean the machine to prevent bacterial growth.

- Check for Wear: Inspect components like heating elements and fans for wear.

- Troubleshooting: Identify common issues such as uneven drying or temperature fluctuations and address them promptly.

Energy Efficiency and Environmental Impact

Modern fish dehydration machines are designed with energy efficiency in mind, often incorporating heat pump technology to reduce energy consumption. This not only saves costs but also minimizes the environmental impact by reducing carbon emissions.

Conclusion

Fish dehydration machines are indispensable in the seafood industry, providing a fast, efficient, and consistent method for drying fish. By understanding how these machines work and their benefits, producers can optimize their use to produce high-quality dried fish products.

FAQs

1. What is the typical temperature range for drying fish in a fish dehydration machine?

The typical temperature range for drying fish is between 40°C to 60°C (104°F to 140°F), depending on the type and thickness of the fish.

2. How does a fish dehydration machine preserve nutrients?

A fish dehydration machine preserves nutrients by using a low-temperature drying process, which helps retain essential nutrients like omega-3 fatty acids.

3. What are the advantages of using a heat pump fish dehydration machine?

Heat pump fish dehydration machines offer energy efficiency, saving up to 75% of electricity compared to traditional drying methods. They also provide a gentle drying process that retains the appearance and aroma of the fish.

4. Can a fish dehydration machine be used for other foods?

Yes, fish dehydration machines can be used to dry various foods, including fruits, vegetables, herbs, and jerky, making them versatile for different applications.

5. How do you ensure uniform drying in a fish dehydration machine?

Uniform drying is achieved through efficient airflow distribution, using fans and strategically placed vents to eliminate moisture pockets and promote consistent drying results.

Citations:

[1] https://www.youtube.com/watch?v=uva-4cXMus0

[2] https://www.bxdrymachine.com/fish-dehydrator.html

[3] https://www.bxdryer.com/news/industry-news/dry-fish-making-machine-news.html

[4] https://airtekdehydrator.com/blog/benefits_of_using_a_fish_dehydrator_machine/

[5] https://airtekdehydrator.com/blog/fish-dryer-machine-guide/

[6] https://machine.goldsupplier.com/blog/fish-drying-machine/

[7] https://dryingplant.com/efficient-fish-drying-techniques-using-a-fish-dehydrator-machine/

[8] https://meat-machine.com/Info/professional-dry-fish-processing-methods/

[9] https://www.aimheatpump.com/pages-49880

[10] https://www.bxdryer.com/news/industry-news/fish-drying-methods-news.html

[11] https://www.shutterstock.com/search/fish-dryer

[12] https://www.shutterstock.com/search/fish-dryers

[13] https://www.youtube.com/watch?v=dxXBo8r5OTw

[14] https://www.loyalfoodmachine.com/automatic-tunnel-type-microwave-food-dehydrator-fish-drying-machine-images/

[15] https://learn.eartheasy.com/guides/a-beginners-guide-to-dehydrating-food/

[16] https://www.fao.org/fishery/docs/CDrom/bobp/cd1/Bobp/Publns/Phf%20News/1995_10.pdf

[17] https://www.bxdrymachine.com/fish-drying-machine.html

[18] https://meat-machine.com/product/fish-dryer-machine/

[19] https://www.bxdryer.com/news/industry-news/fish-drying-process-news.html

[20] https://brightsailmachinery.en.made-in-china.com/product/QAURbucVmnkf/China-Commercial-Small-Fish-Dryer-Drying-Machine-Electric-Seafood-Dryer.html

[21] https://www.joyingmachinery.com/meat-dehydrator/fish-dehydrator/

[22] https://www.youtube.com/watch?v=YrEebcjYzik

[23] https://www.made-in-china.com/products-search/hot-china-products/Wholesale_Fish_Drying_Machine.html

[24] https://www.indiamart.com/proddetail/fish-drying-machine-multipurpose-dryer-17318521230.html

[25] https://www.youtube.com/watch?v=OeKFpy2M0y0

[26] https://www.bxdrymachine.com/fish-dryer.html

[27] https://pleasanthillgrain.com/resources/dehydrators-buying-guide