Content Menu

● Understanding the Heat Pump Dryer

>> Key Features of Heat Pump Dryers

>> How Heat Pump Dryers Work

● Advantages in Food Dehydration

>> Benefits of Low-Temperature Drying

● How Energy is Saved

>> Energy Saving Process

● The Economic Benefits of Using Heat Pump Dryers

>> Case Studies of Energy Savings

● Maintenance Considerations for Heat Pump Dryers

● Conclusion

● Frequently Asked Questions

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer conserve energy?

>> 3. Why are heat pump dryers preferred for food dehydration?

>> 4. What are the key features of a heat pump dryer?

>> 5. How much energy can a heat pump dryer save compared to conventional dryers?

A heat pump dryer has revolutionized the drying technology landscape, particularly in food dehydration. As energy costs rise and the demand for sustainable practices increases, manufacturers are increasingly turning to heat pump dryers for their efficiency and effectiveness. This article will delve into how a good heat pump dryer saves on energy costs, especially in the context of food processing and dehydration.

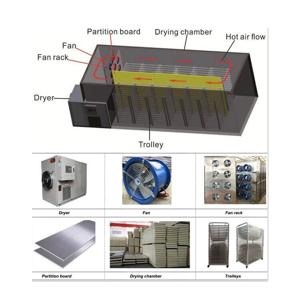

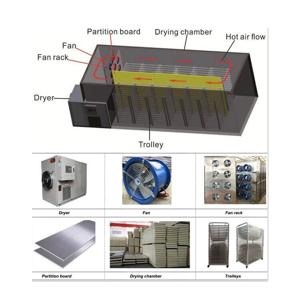

Understanding the Heat Pump Dryer

Heat pump dryers operate on a unique principle that allows them to reclaim and reuse heat that would typically be lost in conventional drying methods. This closed-loop system maximizes energy efficiency, resulting in significant energy savings compared to traditional dryers.

Key Features of Heat Pump Dryers

- Closed-loop System: This innovative system prevents heat from escaping, ensuring that energy is conserved and effectively utilized.

- Dehumidification Process: The dehumidification feature is crucial for energy savings as it provides precise control over temperature and moisture levels, optimizing drying conditions.

- Low Temperature Operation: Heat pump dryers can operate at lower temperatures than conventional dryers, which is particularly beneficial for sensitive food products that may degrade at high temperatures.

How Heat Pump Dryers Work

Heat pump dryers utilize a refrigeration cycle to dry products. The process begins with air being drawn into the dryer where it is heated by a compressor. This warm air then circulates through the food items, absorbing moisture. The now humid air is then passed through an evaporator where it cools down, causing moisture to condense and be collected. The dry air is then reheated and circulated back into the drying chamber. This continuous cycle allows for effective moisture removal while conserving energy.

Heat Pump Dryer Process

Advantages in Food Dehydration

When it comes to food dehydration, maintaining the original quality of the product is essential. Heat pump dryers excel in this area by minimizing nutrient loss and preserving the color and texture of food. The low-temperature drying process reduces thermal damage, making them ideal for various food products.

Benefits of Low-Temperature Drying

- Nutrient Preservation: Many vitamins and minerals are sensitive to heat. By using lower temperatures, heat pump dryers help retain these essential nutrients, ensuring that dried foods remain healthy options.

- Enhanced Flavor Profiles: The gentle drying process helps maintain the natural flavors of fruits, vegetables, and herbs, providing a superior taste compared to products dried at high temperatures.

- Improved Texture: Foods dried at lower temperatures often have a better texture—less brittle and more appealing to consumers.

How Energy is Saved

Heat pump dryers save energy through several mechanisms:

- Recycling Heat: Heat pump dryers capture heat generated during the drying process and reuse it within the system. This reduces the need for additional electricity to create new heat.

- Efficiency at Lower Temperatures: Operating at lower temperatures not only saves energy but also benefits the quality of the food products being dried.

- Reduced Drying Time: The efficient operation of heat pump dryers can lead to shorter drying times compared to traditional methods, further contributing to energy savings.

Energy Saving Process

The process of recycling heat within a heat pump dryer can be illustrated as follows:

1. Air enters the dryer.

2. The compressor heats the air.

3. Warm air circulates through the product.

4. Humid air passes through an evaporator where moisture condenses.

5. Dry air is reheated and cycled back into the dryer.

This cyclical process ensures minimal energy loss while maximizing drying efficiency.

The Economic Benefits of Using Heat Pump Dryers

Investing in heat pump dryers can lead to substantial economic benefits for food manufacturers. Here are some key points:

- Reduced Operating Costs: By consuming less electricity, businesses can significantly lower their operational costs over time. The initial investment in a heat pump dryer is often offset by these savings.

- Increased Production Efficiency: Many manufacturers report enhanced production capabilities when switching to heat pump dryers. For instance, some have seen a fourfold increase in output while simultaneously reducing energy consumption by over 50%.

- Sustainability and Compliance: As environmental regulations become stricter, using energy-efficient equipment like heat pump dryers helps companies comply with sustainability standards while reducing their carbon footprint.

Case Studies of Energy Savings

Several case studies illustrate how businesses have benefited from switching to heat pump dryers:

1. A fruit processing company reported a 40% reduction in energy costs after implementing a heat pump dryer for their operations.

2. A vegetable dehydration facility noted improved product quality alongside a 30% decrease in overall drying time when they transitioned from conventional drying methods to heat pump technology.

3. A herbal tea manufacturer found that using a heat pump dryer not only saved on energy but also enhanced the flavor profile of their dried herbs, leading to increased customer satisfaction.

Maintenance Considerations for Heat Pump Dryers

To ensure optimal performance and longevity of heat pump dryers, regular maintenance is essential:

- Cleaning Filters: Regularly cleaning or replacing filters helps maintain airflow efficiency and ensures that the dryer operates at peak performance.

- Checking Seals and Insulation: Inspecting seals and insulation can prevent energy loss due to leaks, further enhancing efficiency.

- Routine Professional Servicing: Scheduling professional servicing can identify potential issues before they become significant problems, ensuring continuous operation without costly downtime.

Conclusion

In summary, heat pump dryers represent a superior option for industries involved in food processing and dehydration. Their ability to significantly reduce energy consumption not only leads to cost savings but also contributes to more sustainable operations. As manufacturers continue to seek ways to optimize efficiency and reduce costs, heat pump dryers will likely play an increasingly important role in food dehydration processes.

Frequently Asked Questions

1. What is a heat pump dryer?

A heat pump dryer is a machine used for various applications, including food dehydration, which reclaims and reuses heat within a closed-loop system to save energy.

2. How does a heat pump dryer conserve energy?

It conserves energy by capturing and reusing heat from the drying process, thereby reducing the need for additional heat production.

3. Why are heat pump dryers preferred for food dehydration?

They are preferred because they operate at low temperatures, preserving food quality and nutrients while also saving on energy costs.

4. What are the key features of a heat pump dryer?

Key features include a closed-loop system and precise dehumidification controls that enhance energy efficiency.

5. How much energy can a heat pump dryer save compared to conventional dryers?

A heat pump dryer can save between 28% to 50% more energy compared to conventional dryers based on its efficient operation principles.

This comprehensive discussion highlights how good heat pump dryers not only save on energy costs but also enhance product quality and operational efficiency in food processing industries.