Content Menu

● Introduction

● What is a Food Drying Machine?

>> Types of Food Drying Machines

● How Does an Inverter Heat Pump Dryer Work?

>> Benefits of Using an Inverter Heat Pump Dryer

● Applications of Food Drying Machines

>> 1. Agriculture

>> 2. Food Processing Industry

>> 3. Home Use

>> 4. Herbal Medicine Production

>> 5. Snack Food Production

● Comparison with Traditional Drying Methods

>> Energy Efficiency

>> Nutritional Preservation

● Choosing the Right Food Drying Machine

● Maintenance Tips for Inverter Heat Pump Dryers

● Innovations in Food Drying Technology

>> Smart Technology Integration

>> Enhanced Energy Recovery Systems

>> Eco-Friendly Materials

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is an inverter heat pump dryer?

>> 2. How does an inverter heat pump dryer save energy?

>> 3. Can I use an inverter heat pump dryer for all types of food?

>> 4. How long does it take to dry food using an inverter heat pump dryer?

>> 5. Are inverter heat pump dryers suitable for home use?

Introduction

Food preservation has been an essential practice throughout human history, and with advancements in technology, we now have more efficient methods to achieve this. One such innovation is the inverter heat pump dryer. This article explores the workings, benefits, and applications of food drying machines, particularly focusing on inverter heat pump dryers. We will delve into how these machines differ from traditional drying methods and why they are becoming increasingly popular in the food industry.

What is a Food Drying Machine?

A food drying machine is a device designed to remove moisture from food products, extending their shelf life while maintaining nutritional value and flavor. These machines utilize various drying methods, including convection, freeze-drying, and heat pump technology.

Types of Food Drying Machines

- Convection Dryers: Use hot air to circulate around the food. They are common in both home and commercial settings but can lead to uneven drying if not monitored.

- Freeze Dryers: Remove moisture by freezing the food and then reducing the surrounding pressure. This method retains most nutrients but is often more expensive and requires more energy.

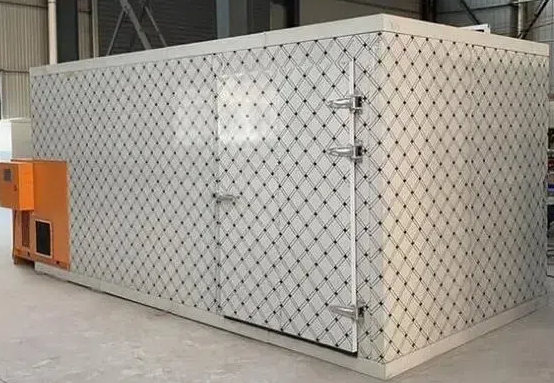

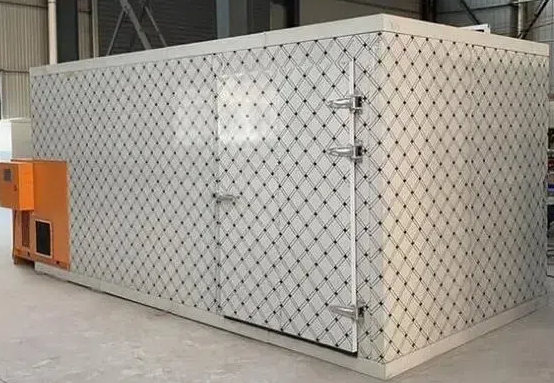

- Inverter Heat Pump Dryers: Utilize a heat pump system to efficiently extract moisture at lower temperatures. They offer superior energy efficiency and are increasingly favored in both commercial and home applications.

How Does an Inverter Heat Pump Dryer Work?

An inverter heat pump dryer operates by transferring heat from the environment to the drying chamber. Here's a breakdown of its operation:

1. Heat Absorption: The machine absorbs ambient air using a fan.

2. Heat Pump Cycle: The absorbed air is compressed, raising its temperature significantly.

3. Moisture Extraction: This hot air is then circulated through the drying chamber, where it evaporates moisture from the food.

4. Condensation: The moisture-laden air is cooled down, causing the water vapor to condense and be collected.

5. Recycling Air: The now-dry air is reheated and recirculated for further drying.

Benefits of Using an Inverter Heat Pump Dryer

- Energy Efficiency: Inverter technology allows for variable speed operation, reducing energy consumption compared to traditional dryers.

- Lower Temperature Drying: This method preserves the nutritional content and flavor of food better than high-temperature drying methods.

- Versatility: Suitable for a wide range of products including fruits, vegetables, meats, and herbs.

- Environmentally Friendly: Uses less energy and emits fewer greenhouse gases compared to conventional dryers.

- Quality Preservation: The gentle drying process helps retain the color, taste, and texture of food products better than other methods.

Applications of Food Drying Machines

Food drying machines are widely used in various sectors:

1. Agriculture

Farmers use dryers to process surplus crops, reducing waste and increasing profitability. By converting excess produce into dried products, farmers can extend the shelf life of their harvests significantly. This not only helps in managing seasonal fluctuations but also opens up new markets for dried goods.

2. Food Processing Industry

Manufacturers dry fruits, vegetables, and meats to create snacks and ingredients for other products. Dried fruits are popular as healthy snacks or baking ingredients, while dried vegetables can be used in soups and sauces. The ability to control moisture levels allows manufacturers to create consistent products that meet consumer demands for quality and safety.

3. Home Use

Consumers are increasingly investing in home dryers for personal use, allowing them to preserve seasonal produce. Home users appreciate the convenience of drying their own fruits and vegetables, which can be used in meals or as snacks throughout the year. Inverter heat pump dryers are particularly appealing for home use due to their compact size and energy efficiency.

4. Herbal Medicine Production

Drying herbs at lower temperatures helps retain their medicinal properties. Herbalists often rely on inverter heat pump dryers to ensure that active compounds remain intact during the drying process, resulting in higher-quality herbal products that are rich in flavor and efficacy.

5. Snack Food Production

The snack food industry has seen a surge in demand for dried fruits and vegetables as healthy alternatives to traditional snacks. Inverter heat pump dryers enable producers to create high-quality snacks that appeal to health-conscious consumers without compromising on taste or texture.

Comparison with Traditional Drying Methods

When comparing inverter heat pump dryers with traditional drying methods such as sun drying or conventional electric dryers, several factors come into play:

| Feature | Inverter Heat Pump Dryer | Traditional Dryers |

|-----------------------------|--------------------------|-------------------------|

| Energy Consumption | Low | High |

| Temperature Control | Precise | Limited |

| Nutritional Preservation | High | Moderate |

| Moisture Control | Excellent | Variable |

| Initial Cost | Higher | Lower |

| Drying Time | Consistent | Variable |

Energy Efficiency

Inverter heat pump dryers significantly reduce energy consumption by using advanced technology that adjusts power usage based on load requirements. Traditional dryers tend to operate at fixed power levels regardless of how much product is being dried.

Nutritional Preservation

The ability of inverter heat pump dryers to operate at lower temperatures means that they can preserve more vitamins and minerals compared to traditional methods that often rely on high heat levels that can degrade sensitive nutrients.

Choosing the Right Food Drying Machine

When selecting a food drying machine, consider the following factors:

- Capacity: Determine how much food you plan to dry at once. Larger capacities may be necessary for commercial operations while smaller units may suffice for home use.

- Energy Efficiency Rating: Look for models with high energy efficiency ratings to save on electricity bills over time.

- Temperature Range: Ensure the dryer can operate at low temperatures for sensitive foods like herbs or delicate fruits.

- Ease of Use: Consider user-friendly controls and features like timers and automatic shut-off mechanisms for added convenience.

- Brand Reputation: Research brands known for reliability and customer service support; this can greatly influence your satisfaction with your purchase.

Maintenance Tips for Inverter Heat Pump Dryers

To ensure longevity and optimal performance of your inverter heat pump dryer:

1. Regular Cleaning: Clean filters and fans regularly to maintain airflow. Dust accumulation can hinder performance and increase energy consumption.

2. Check Seals: Inspect door seals for wear and tear to prevent heat loss; damaged seals can lead to inefficient operation.

3. Monitor Performance: Keep an eye on drying times; if they increase significantly, it may indicate a need for maintenance or repairs.

4. Professional Servicing: Schedule professional check-ups annually to keep your machine in top shape; experts can identify potential issues before they become major problems.

5. Follow Manufacturer Guidelines: Adhere strictly to maintenance guidelines provided by the manufacturer for optimal performance and longevity of your dryer.

Innovations in Food Drying Technology

The field of food drying technology is continuously evolving with innovations aimed at improving efficiency, quality, and sustainability:

Smart Technology Integration

Many modern inverter heat pump dryers come equipped with smart technology features that allow users to monitor and control their machines remotely via smartphone apps. This capability provides convenience as users can adjust settings without being physically present near the machine.

Enhanced Energy Recovery Systems

Newer models are incorporating advanced energy recovery systems that capture waste heat generated during operation, redirecting it back into the drying process. This innovation further enhances energy efficiency by minimizing waste.

Eco-Friendly Materials

Manufacturers are increasingly focusing on using eco-friendly materials in their dryer designs which not only reduces environmental impact but also improves durability over time.

Conclusion

In conclusion, inverter heat pump dryers represent a significant advancement in food preservation technology. Their energy efficiency, ability to operate at lower temperatures, versatility across various food types, and innovative features make them an excellent choice for both commercial producers and home users alike. As we continue to seek sustainable solutions in food processing, these machines will undoubtedly play a crucial role in shaping the future of food preservation.

This article has explored various aspects of inverter heat pump dryers and their applications in the food industry. By understanding their benefits and operational mechanisms, businesses can make informed decisions about investing in this innovative technology that not only meets modern demands but also supports environmental sustainability efforts through reduced energy consumption.

Frequently Asked Questions (FAQs)

1. What is an inverter heat pump dryer?

An inverter heat pump dryer is a type of food drying machine that uses heat pump technology to efficiently remove moisture from food at lower temperatures while conserving energy.

2. How does an inverter heat pump dryer save energy?

It uses variable speed operation that adjusts according to the load size and moisture content, leading to reduced energy consumption compared to traditional dryers that operate at fixed speeds.

3. Can I use an inverter heat pump dryer for all types of food?

Yes, inverter heat pump dryers are versatile and can be used for a wide range of foods including fruits, vegetables, meats, herbs, and even flowers for decorative purposes or essential oils extraction.

4. How long does it take to dry food using an inverter heat pump dryer?

Drying times vary based on the type of food being dried and its moisture content but generally range from a few hours to overnight for most products depending on thickness and initial moisture levels.

5. Are inverter heat pump dryers suitable for home use?

Absolutely! Many consumers are adopting inverter heat pump dryers for home use due to their efficiency and ability to preserve food quality effectively while being compact enough for kitchen spaces or small storage areas.