Content Menu

● Key Efficiency-Boosting Components

>> Heat Pump Dehydration Chambers

● Advanced Technological Innovations

>> 1. AI-Powered Moisture Prediction

>> 2. Hybrid Energy Systems

>> 3. Sanitary Design Features

>> 4. Smart Inventory Management

● Extended Efficiency Enhancement Mechanisms

● Production Workflow Optimization

● Case Study: Operational Transformation

● Cost Efficiency Analysis

● Environmental Impact

● Maintenance Protocols

● Global Market Insights

● Conclusion

● FAQ

>> 1. What's the ideal onion slice thickness for machine drying?

>> 2. How does temperature affect dehydration efficiency?

>> 3. What maintenance do these machines require?

>> 4. Can machines handle different onion varieties?

>> 5. How does machine drying compare to solar alternatives?

● Citations:

Modern onion dehydration machines revolutionize food processing through advanced drying technologies that enhance output consistency while reducing operational costs. These industrial systems combine thermal engineering with intelligent automation to achieve superior production efficiency compared to traditional drying methods.

Key Efficiency-Boosting Components

Three primary machine types dominate commercial onion dehydration:

Heat Pump Dehydration Chambers

- Energy Recovery System: Recaptures 70-75% of thermal energy

- Batch Capacity: 100-5,000kg per cycle

- Temperature Precision: ±1°C control via PLC systems

Technical Specifications (Typical Model):

| Parameter | GG-3P | GG-7P | GG-15P |

| Dehydration Capacity | 9kg/h | 21kg/h | 43kg/h |

| Power Consumption | 4kW | 12kW | 21kW |

| Temperature Range | 30-75°C | 30-75°C | 30-75°C |

Advanced Technological Innovations

Five cutting-edge features enhance modern onion dehydration machines:

1. AI-Powered Moisture Prediction

- Infrared Sensors: Monitor real-time moisture gradients

- Algorithmic Adjustments: Auto-optimize drying parameters

- Error Reduction: 92% accurate vs manual testing

2. Hybrid Energy Systems

- Solar-Assisted Models: Reduce grid dependency by 40%

- Biomass Integration: 100% renewable operation capability

3. Sanitary Design Features

- FDA-Compliant Surfaces: 304/316L stainless steel construction

- CIP Systems: Automated cleaning reduces downtime by 65%

4. Smart Inventory Management

- Batch Tracking: RFID tagging for full traceability

- Cloud Integration: Sync with ERP/MES systems

Extended Efficiency Enhancement Mechanisms

Six operational advantages drive production improvements:

1. Accelerated Drying Cycles

- 3-4kg water removal/hour vs 0.5-1kg in sun drying

- 8-hour batch processing vs 3-5 days traditional methods

2. Precision Controls

- PLC + Touchscreen Interfaces: Program multiple drying profiles

- Humidity Sensors: Maintain 20-30% RH optimal conditions

- Auto-Shutoff: Prevents over-drying

Thermal Efficiency Comparison

| Slice Thickness | Solar Dryer Efficiency | Machine Dryer Efficiency |

| 2mm | 19.5% | 27.89% |

| 4mm | 22.63% | 34.12% |

3. Quality Preservation

- Color Retention: 95% original pigmentation

- Nutritional Preservation: <5% vitamin C loss

- Rehydration Capacity: Maintains 1:3.5 water ratio

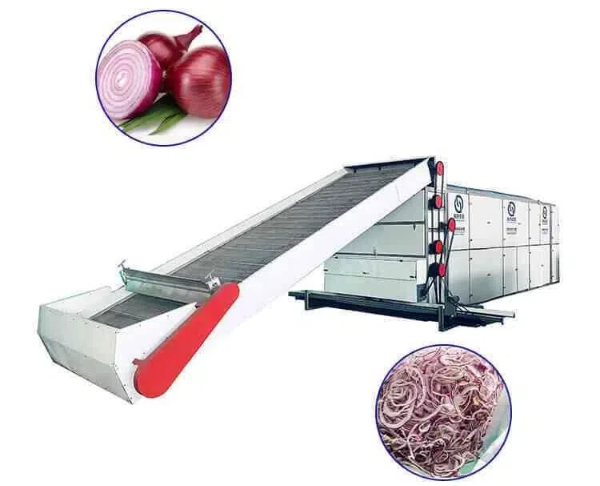

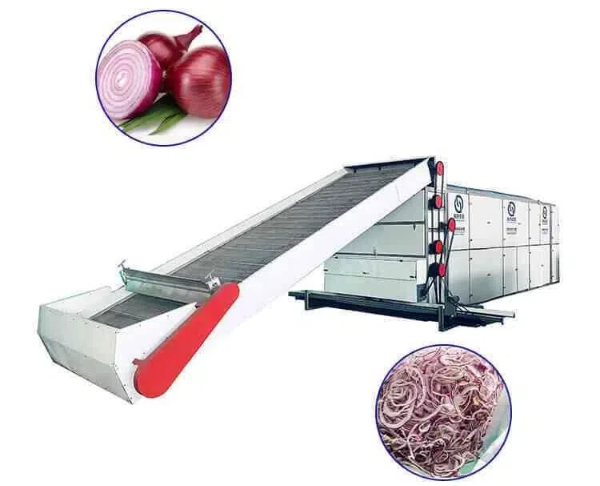

4. Scalable Automation

- Loading Systems: Conveyor belt vs tray configurations

- Continuous Operation: 24/7 production capability

- Remote Monitoring: IoT-enabled performance tracking

5. Waste Reduction Systems

- Condensate Recovery: 85% water reuse potential

- Peel/Slice Byproduct Processing: Integrated grinding for powder production

6. Adaptive Climate Control

- Altitude Compensation: Automatic pressure adjustments

- Humidity Lockout: Prevents moisture reabsorption

Production Workflow Optimization

Standardized Processing Stages:

1. Pre-treatment

- Peeling: Rotary abrasive systems

- Slicing: 2-4mm uniform cuts

2. Loading

- Tray Density: 5-7kg/m²

- Airflow Configuration: Vertical/horizontal patterns

3. Dehydration

- Phase 1 (0-2hrs): 65-75°C moisture removal

- Phase 2 (2-6hrs): 55-60°C equilibrium drying

- Phase 3 (6-8hrs): 45-50°C final curing

4. Packaging

- Moisture Content: <8% for powder production

- Cooling Period: 45-60 minute stabilization

Case Study: Operational Transformation

California AgriFoods Inc. implemented onion dehydration machines with these results:

| Metric | Pre-Implementation | Post-Implementation |

| Daily Output | 1.2 tons | 4.8 tons |

| Energy Cost/ton | $38 | $22 |

| Labor Hours/ton | 8.5 | 1.2 |

| Product Reject Rate | 17% | 3.1% |

Cost Efficiency Analysis

Operational Comparison (Per Ton):

| Factor | Traditional | Machine |

| Labor | 12-15hrs | 2-3hrs |

| Energy | N/A | $18-25 |

| Space | 200m² | 30m² |

| Yield Loss | 15-20% | 3-5% |

ROI Calculation Example:

- Machine Cost: $50,000-$150,000

- Output Value: $2,800/ton (dehydrated) vs $400/ton (fresh)

- Payback Period: 14-18 months at 5ton/day capacity

Environmental Impact

Sustainability Benefits:

- Energy Savings: 75% reduction vs conventional dryers

- Carbon Footprint: 2.1kg CO₂/ton vs 8.7kg in sun drying

- Water Conservation: 850L/ton water recovery

Maintenance Protocols

Three-Level Maintenance System:

1. Daily:

- Air filter cleaning

- Belt tension checks

2. Weekly:

- Heat exchanger brushing

- Sensor calibration

3. Annual:

- Motor bearing replacement

- Refrigerant recharge

Global Market Insights

2025 Dehydrated Onion Trends:

Demand Growth: 6.8% CAGR (2023-2030)

Top Applications:

1. Instant soups (34% market share)

2. Seasoning blends (28%)

3. Pet food additives (19%)

Regulatory Compliance:

- Certifications: HACCP, ISO 22000, USDA Organic

- Packaging Standards: ASTM D4169 vibration testing

Conclusion

Modern onion dehydration machines deliver 3X production capacity versus traditional methods through intelligent moisture control (95% accuracy), energy-efficient operation (75% savings), and automated quality management. These systems enable manufacturers to achieve ROI within 18 months while meeting growing global demand for shelf-stable onion products.

FAQ

1. What's the ideal onion slice thickness for machine drying?

Optimal thickness ranges 2-4mm to balance drying speed (5-8 hours) with nutrient preservation.

2. How does temperature affect dehydration efficiency?

Controlled 55-75°C ranges maximize moisture removal (3-4kg/hr) while preventing case hardening.

3. What maintenance do these machines require?

Daily filter cleaning, weekly belt adjustments, and quarterly heat exchanger servicing.

4. Can machines handle different onion varieties?

Yes - white, yellow, and red onions all process effectively at 60-70°C settings.

5. How does machine drying compare to solar alternatives?

Industrial dryers achieve 27-34% thermal efficiency vs 19-22% in solar systems.

Citations:

[1] https://www.bxdryer.com/news/industry-news/onion-dehydration-plant-news.html

[2] https://www.onionmachines.com/product/onion-dehydration-machine/

[3] https://www.indiamart.com/proddetail/onion-dehydration-machine-2852400645312.html

[4] https://www.youtube.com/watch?v=wxNc7bBFon8

[5] https://www.cravethegood.com/how-to-dehydrate-onions/

[6] https://www.bxdryer.com/news/industry-news/onion-dehydrator-machine-news.html

[7] https://asmedigitalcollection.asme.org/solarenergyengineering/article/147/1/014501/1201585/Dehydration-of-Onion-Slices-for-Food-Processing

[8] https://www.indiamart.com/proddetail/onion-drying-machine-24001717991.html

[9] https://www.youtube.com/watch?v=jTH-z7k0wuQ

[10] https://www.youtube.com/watch?v=mdHKmigQEaw

[11] https://airtekdehydrator.com/onion-dryer-and-the-food-processing-industry/

[12] https://yourequipmentsuppliers.com/blogs/5-benefits-of-food-dehydration/

[13] https://www.healthline.com/nutrition/dehydrated-food

[14] https://www.onionmachines.com/product/onion-dehydration-machinery/

[15] https://nondestructive.asmedigitalcollection.asme.org/solarenergyengineering/article-pdf/147/1/014501/7357768/sol_147_1_014501.pdf

[16] https://stock.adobe.com/search/images?k=dehydrated+onion

[17] https://www.pinterest.com/pin/841821355355908168/

[18] https://pmc.ncbi.nlm.nih.gov/articles/PMC4325018/

[19] https://www.made-in-china.com/products-search/hot-china-products/Onion_Dryer_Machine.html

[20] https://www.backpackingchef.com/dehydrating-onions.html