Content Menu

● Introduction

● Understanding the Basic Principles

>> Key Components

● The Drying Process Step by Step

>> 1. Initial Air Heating

>> 2. Moisture Extraction

>> 3. Condensation Process

● Advanced Technology Features

>> Temperature Control

>> Energy Recovery System

● Benefits of Heat Pump Technology

>> Energy Efficiency

>> Fabric Care

● Installation and Space Requirements

>> Location Considerations

● Maintenance Requirements

>> Regular Care

● Environmental Impact

>> Sustainability Features

● Smart Features and Innovation

>> Modern Capabilities

● Cost Considerations

>> Investment Analysis

● Comparison with Traditional Dryers

>> Key Differences

● Conclusion

● Frequently Asked Questions

>> Q1: How long does a typical drying cycle take in a heat pump dryer?

>> Q2: Do heat pump dryers require special maintenance?

>> Q3: Can heat pump dryers be installed anywhere in the home?

>> Q4: How much energy do heat pump dryers save compared to conventional dryers?

>> Q5: Are heat pump dryers worth the higher initial investment?

Introduction

Ventless heat pump dryers represent a revolutionary advancement in laundry technology, offering an energy-efficient and environmentally friendly alternative to traditional vented dryers. This comprehensive guide explores the intricate workings of these innovative appliances.

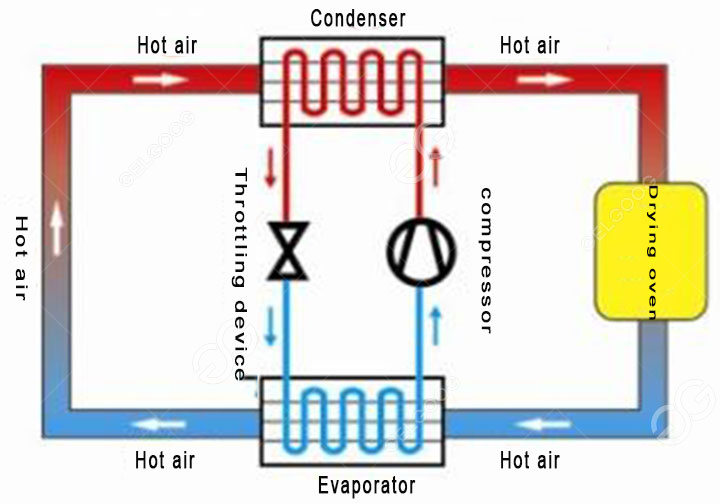

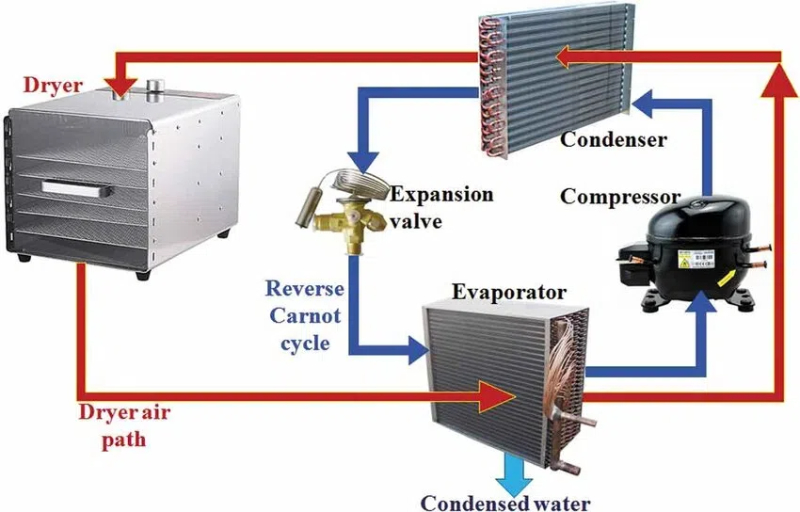

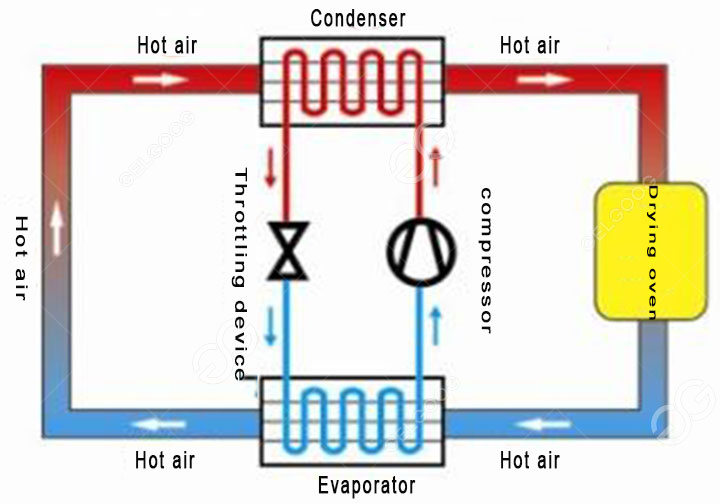

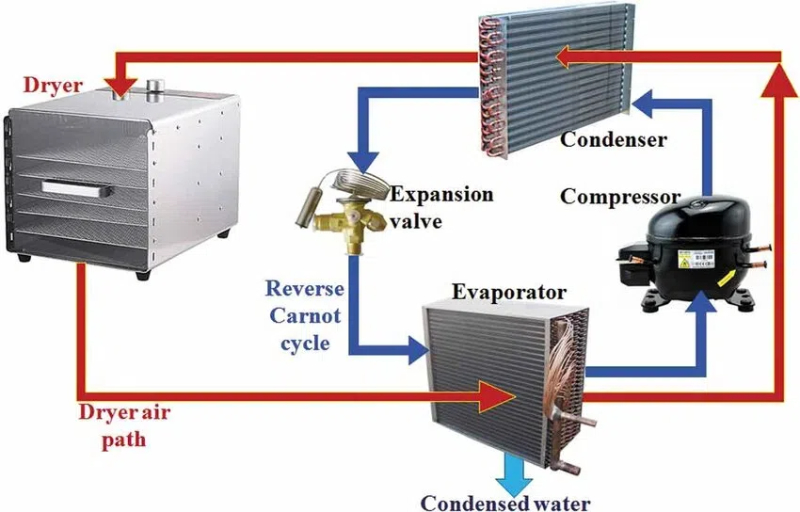

Understanding the Basic Principles

A ventless heat pump dryer operates on a closed-loop system that continuously recycles air within the machine. Unlike conventional dryers that expel hot, humid air outside, these systems use advanced heat exchange technology to process and reuse the air efficiently.

Key Components

- Heat pump unit

- Evaporator

- Condenser

- Compressor

- Sealed air circulation system

- Water collection system

The Drying Process Step by Step

1. Initial Air Heating

The process begins when the heat pump warms the air using a refrigerant-based system. This heated air is then circulated through the drum containing wet clothes.

2. Moisture Extraction

As the warm air passes through the clothes, it absorbs moisture from the fabrics. This moisture-laden air then enters the cooling phase of the cycle.

3. Condensation Process

The humid air passes through an evaporator, where it's cooled rapidly. This cooling causes the moisture to condense into water droplets.

Advanced Technology Features

Temperature Control

Heat pump dryers maintain lower drying temperatures compared to conventional dryers, typically operating between 50-60°C. This gentler approach helps protect fabrics while still achieving excellent drying results.

Energy Recovery System

The system recovers and reuses heat energy throughout the drying cycle, significantly reducing energy consumption compared to traditional dryers.

Benefits of Heat Pump Technology

Energy Efficiency

- Reduced power consumption

- Lower operating costs

- Improved environmental impact

- Energy rating advantages

Fabric Care

- Gentler drying process

- Reduced wear and tear

- Better color preservation

- Less static electricity

Installation and Space Requirements

Location Considerations

- Adequate ventilation

- Level surface

- Appropriate room temperature

- Proper clearance space

Maintenance Requirements

Regular Care

- Filter cleaning

- Condenser maintenance

- Water tank emptying

- Sensor cleaning

- Drum inspection

Environmental Impact

Sustainability Features

- Reduced carbon footprint

- Water conservation

- Energy efficiency

- Eco-friendly operation

Smart Features and Innovation

Modern Capabilities

- Moisture sensing

- Automatic programming

- Smart connectivity

- Custom cycle options

Cost Considerations

Investment Analysis

- Initial purchase price

- Operating costs

- Energy savings

- Maintenance expenses

- Long-term benefits

Comparison with Traditional Dryers

Key Differences

- Energy consumption

- Drying time

- Installation requirements

- Maintenance needs

- Environmental impact

Conclusion

Ventless heat pump dryers represent the future of laundry technology, offering superior energy efficiency, excellent fabric care, and environmental benefits. While they require a higher initial investment, their long-term advantages make them an increasingly popular choice for environmentally conscious consumers seeking efficient laundry solutions.

Frequently Asked Questions

Q1: How long does a typical drying cycle take in a heat pump dryer?

A: Heat pump dryers typically take longer than conventional dryers, with average cycle times ranging from 90-120 minutes. However, this longer drying time is offset by significantly lower energy consumption and gentler fabric care.

Q2: Do heat pump dryers require special maintenance?

A: While heat pump dryers do require regular maintenance, it's relatively simple. Key maintenance tasks include cleaning the lint filter after each use, regularly cleaning the heat exchanger, and ensuring the condensation system is functioning properly.

Q3: Can heat pump dryers be installed anywhere in the home?

A: Heat pump dryers offer flexible installation options as they don't require external venting. However, they need adequate ventilation space around the unit and should be installed in an area with room temperature between 5-35°C for optimal performance.

Q4: How much energy do heat pump dryers save compared to conventional dryers?

A: Heat pump dryers typically use about 50% less energy than conventional dryers. This significant reduction in energy consumption leads to lower operating costs and reduced environmental impact.

Q5: Are heat pump dryers worth the higher initial investment?

A: While heat pump dryers have a higher purchase price, they often prove cost-effective in the long run through reduced energy bills, gentler treatment of clothes (leading to longer garment life), and lower environmental impact. The payback period typically ranges from 3-5 years, depending on usage patterns.