Content Menu

● Introduction

● Understanding Dry Food Packaging Machines

>> Key Components of a Dry Food Packaging Machine

● Types of Dry Food Packaging Machines

>> 1. Vertical Form Fill Seal Machine (VFFS)

>> 2. Multi-head Weigher Packaging System

>> 3. Pouch Packaging Machine for Dry Foods

>> 4. Bulk Dry Food Packaging Solutions

● Benefits of Using Dry Food Packaging Machines

>> 1. Increased Efficiency

>> 2. Improved Accuracy

>> 3. Enhanced Food Safety

>> 4. Cost-Effective

>> 5. Versatility

● Choosing the Right Dry Food Packaging Machine

>> 1. Product Characteristics

>> 2. Production Volume

>> 3. Packaging Material

>> 4. Flexibility

>> 5. Maintenance and Support

● Innovations in Dry Food Packaging Technology

>> 1. Smart Packaging Solutions

>> 2. Sustainable Packaging Options

>> 3. Advanced Sealing Technologies

>> 4. Customization Capabilities

● Impact on the Food Industry

>> 1. Increased Product Shelf Life

>> 2. Improved Supply Chain Efficiency

>> 3. Enhanced Brand Presentation

>> 4. Adaptation to E-commerce

● Future Trends in Dry Food Packaging

>> 1. Artificial Intelligence Integration

>> 2. Increased Automation

>> 3. Nano-technology in Packaging

>> 4. Virtual and Augmented Reality

● Conclusion

● Frequently Asked Questions

>> Q1: What are the main advantages of using a dry food packaging machine?

>> Q2: How do I choose the right dry food packaging machine for my business?

>> Q3: Can dry food packaging machines handle different types of packaging materials?

>> Q4: How do dry food packaging machines contribute to food safety?

>> Q5: What are some emerging trends in dry food packaging machine technology?

Introduction

In today's fast-paced food industry, efficiency and quality are paramount. Dry food packaging machines have emerged as a game-changing technology, streamlining production processes and ensuring the highest standards of food safety and preservation. This comprehensive guide will explore the world of dry food packaging machines, their benefits, types, and impact on the food industry.

Understanding Dry Food Packaging Machines

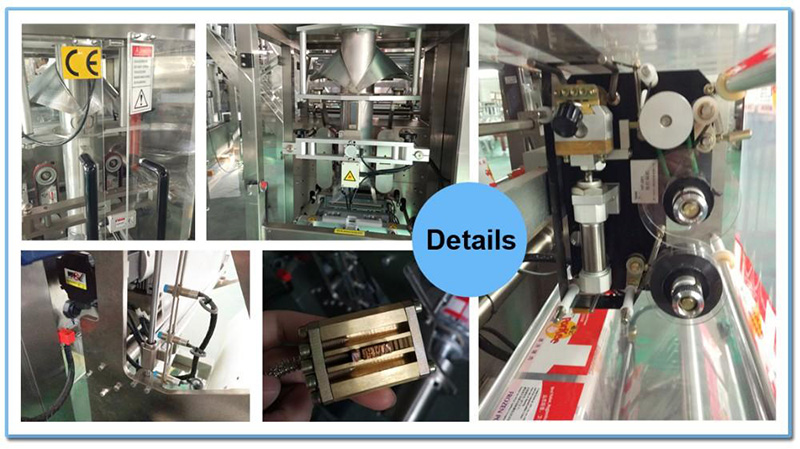

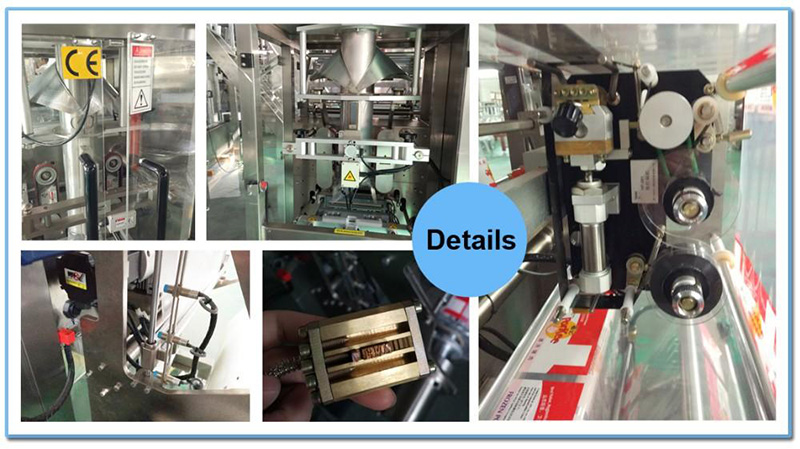

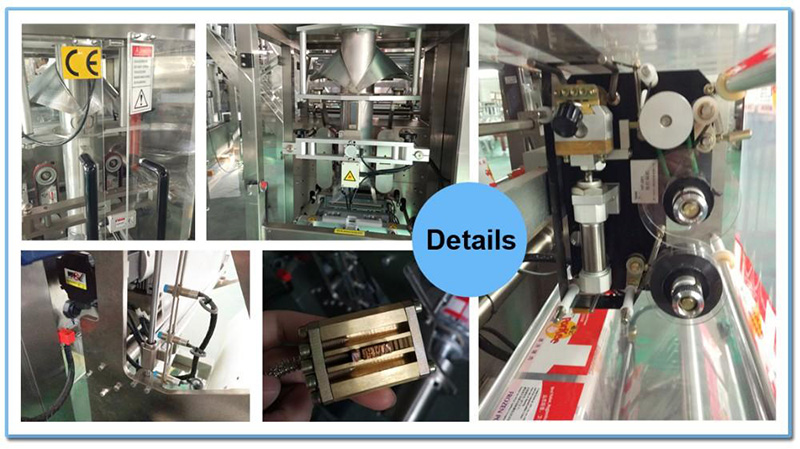

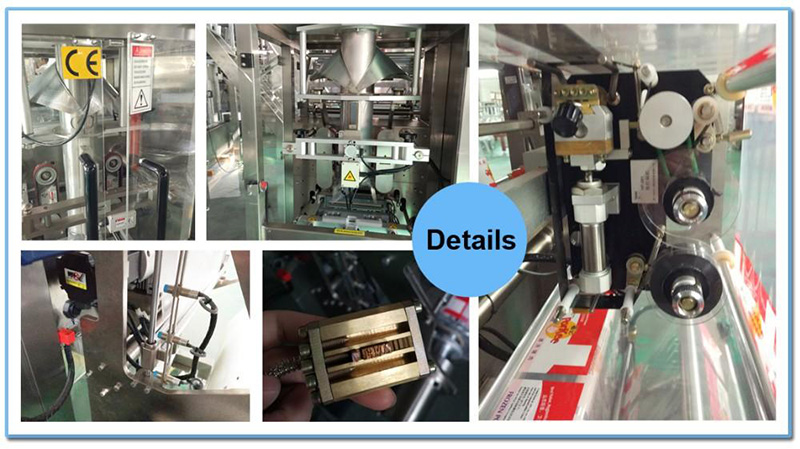

Dry food packaging machines are sophisticated pieces of equipment designed to automate the process of packaging dry food products such as grains, nuts, snacks, and powders. These machines combine precision engineering with cutting-edge technology to deliver fast, accurate, and hygienic packaging solutions.

Key Components of a Dry Food Packaging Machine

1. Feeding system

2. Weighing mechanism

3. Filling station

4. Sealing unit

5. Conveyor system

6. Control panel

Types of Dry Food Packaging Machines

1. Vertical Form Fill Seal Machine (VFFS)

The vertical form fill seal machine is a popular choice for packaging dry foods. It creates bags from a flat roll of film, fills them with product, and seals them in one continuous process. VFFS machines are known for their versatility and high-speed operation.

2. Multi-head Weigher Packaging System

This system combines a multi-head weigher with a packaging machine to ensure accurate weight measurements before packaging. It's ideal for products that require precise portioning, such as nuts, dried fruits, and snack mixes.

3. Pouch Packaging Machine for Dry Foods

Pouch packaging machines are designed to fill and seal pre-made pouches with dry food products. They offer flexibility in terms of pouch sizes and styles, making them suitable for a wide range of products.

4. Bulk Dry Food Packaging Solutions

For large-scale operations, bulk dry food packaging solutions offer high-capacity packaging capabilities. These systems can handle large volumes of product and are often used in industrial settings.

Benefits of Using Dry Food Packaging Machines

1. Increased Efficiency

Dry food packaging machines significantly boost production efficiency by automating the packaging process. They can package hundreds or even thousands of units per hour, far surpassing manual packaging speeds.

2. Improved Accuracy

With precise weighing mechanisms and controlled filling processes, these machines ensure consistent product quantities in each package, reducing waste and improving customer satisfaction.

3. Enhanced Food Safety

By minimizing human contact with the product, dry food packaging machines help maintain hygiene standards and reduce the risk of contamination. Many machines are designed with food-grade materials and easy-to-clean components.

4. Cost-Effective

While the initial investment in a dry food packaging machine may be significant, the long-term benefits in terms of labor savings, reduced waste, and increased output make it a cost-effective solution for many businesses.

5. Versatility

Modern dry food packaging machines can handle a wide variety of products and packaging formats, allowing businesses to adapt to changing market demands and product lines.

Choosing the Right Dry Food Packaging Machine

Selecting the appropriate packaging machine for your dry food products requires careful consideration of several factors:

1. Product Characteristics

Consider the size, shape, and texture of your dry food products. Some machines are better suited for powders, while others excel at handling larger items like nuts or dried fruits.

2. Production Volume

Assess your current and projected production needs. High-speed food packaging automation may be necessary for large-scale operations, while smaller businesses might opt for more compact solutions.

3. Packaging Material

Different machines are designed to work with specific packaging materials. Ensure that the machine you choose is compatible with your preferred packaging type, whether it's plastic films, pouches, or other materials.

4. Flexibility

If you produce a variety of products or anticipate changes in your product line, look for a machine that offers flexibility in terms of package sizes and styles.

5. Maintenance and Support

Consider the availability of spare parts, technical support, and maintenance services when choosing a machine. Reliable after-sales support can significantly impact the long-term performance of your packaging line.

Innovations in Dry Food Packaging Technology

The field of dry food packaging is constantly evolving, with new technologies emerging to meet the changing needs of the industry and consumers.

1. Smart Packaging Solutions

Integration of IoT (Internet of Things) technology allows for real-time monitoring of packaging processes, predictive maintenance, and data-driven optimization of production lines.

2. Sustainable Packaging Options

Many modern dry food packaging machines are designed to work with eco-friendly packaging materials, responding to the growing demand for sustainable packaging solutions.

3. Advanced Sealing Technologies

Innovations in sealing technologies, such as ultrasonic sealing, are improving package integrity and extending shelf life for dry food products.

4. Customization Capabilities

Some cutting-edge machines offer on-the-fly customization options, allowing for personalized packaging or promotional materials to be incorporated into the packaging process.

Impact on the Food Industry

The adoption of dry food packaging machines has had a profound impact on the food industry:

1. Increased Product Shelf Life

By providing consistent, high-quality seals and the option for modified atmosphere packaging, these machines help extend the shelf life of dry food products.

2. Improved Supply Chain Efficiency

The speed and reliability of automated packaging systems have streamlined supply chains, allowing for faster turnaround times and more responsive inventory management.

3. Enhanced Brand Presentation

High-quality, consistent packaging produced by these machines helps brands maintain a professional image and stand out on store shelves.

4. Adaptation to E-commerce

With the rise of online food sales, dry food packaging machines have evolved to create packaging that is both attractive and durable enough to withstand the rigors of shipping.

Future Trends in Dry Food Packaging

As we look to the future, several trends are shaping the evolution of dry food packaging machines:

1. Artificial Intelligence Integration

AI-powered systems are being developed to optimize packaging processes, predict maintenance needs, and even adjust packaging parameters based on product characteristics.

2. Increased Automation

The trend towards fully automated packaging lines is expected to continue, with robots and autonomous systems playing a larger role in the packaging process.

3. Nano-technology in Packaging

Emerging nano-technologies may soon be incorporated into packaging machines, offering new possibilities for food preservation and smart packaging solutions.

4. Virtual and Augmented Reality

VR and AR technologies are being explored for training operators, troubleshooting machines, and visualizing packaging designs before production.

Conclusion

Dry food packaging machines have revolutionized the food industry, offering unparalleled efficiency, consistency, and quality in packaging dry food products. As technology continues to advance, these machines will play an increasingly crucial role in meeting the demands of a growing global population and evolving consumer preferences. By staying informed about the latest developments in dry food packaging technology, food manufacturers can ensure they remain competitive and continue to deliver high-quality products to their customers.

Frequently Asked Questions

Q1: What are the main advantages of using a dry food packaging machine?

A1: The main advantages include increased efficiency, improved accuracy in product quantity, enhanced food safety through reduced human contact, cost-effectiveness in the long run, and versatility in handling various products and packaging formats.

Q2: How do I choose the right dry food packaging machine for my business?

A2: Consider factors such as your product characteristics, production volume, preferred packaging material, need for flexibility, and available maintenance and support. It's also important to assess your current and future production needs to ensure the machine can scale with your business.

Q3: Can dry food packaging machines handle different types of packaging materials?

A3: Yes, many modern dry food packaging machines are designed to work with a variety of packaging materials. However, it's important to choose a machine that is compatible with your specific packaging needs, whether that's plastic films, pouches, or other materials.

Q4: How do dry food packaging machines contribute to food safety?

A4: These machines minimize human contact with the product, reducing the risk of contamination. They are often made with food-grade materials and have easy-to-clean components. Many also offer options for modified atmosphere packaging, which can extend shelf life and maintain product freshness.

Q5: What are some emerging trends in dry food packaging machine technology?

A5: Some key trends include the integration of artificial intelligence for process optimization, increased automation with robotics, the use of nano-technology in packaging, and the application of virtual and augmented reality for machine operation and maintenance. There's also a growing focus on machines that can handle sustainable packaging materials.