Content Menu

● Introduction

● The Importance of Dry Food Packaging

>> Key Benefits of Advanced Dry Food Packaging Solutions

● Types of Dry Food Packing Machines

>> 1. Vertical Form Fill Seal (VFFS) Machines

>> 2. Multi-Head Weigher Packaging Systems

>> 3. Vacuum Sealing Machines for Dry Foods

>> 4. Horizontal Flow Wrap Machines

● Advanced Features in Modern Dry Food Packaging Equipment

>> 1. Intelligent Control Systems

>> 2. Servo-Driven Technology

>> 3. Integrated Vision Systems

>> 4. Remote Monitoring and Diagnostics

● Choosing the Right Dry Food Packing Machine Manufacturer

>> 1. Experience and Reputation

>> 2. Range of Solutions

>> 3. Innovation and Technology

>> 4. After-Sales Support

>> 5. Compliance and Certifications

● The Future of Dry Food Packaging

>> 1. Sustainable Packaging Solutions

>> 2. Smart Packaging

>> 3. Flexible Packaging

>> 4. Automation and Industry 4.0

● Case Study: Implementing a High-Speed Packaging Line

● Conclusion

● Frequently Asked Questions

>> 1. What is the average lifespan of a dry food packing machine?

>> 2. How do I determine the right packaging speed for my production line?

>> 3. Can dry food packing machines handle different package sizes and formats?

>> 4. What are the key maintenance requirements for dry food packaging equipment?

>> 5. How can I ensure my packaging line complies with food safety regulations?

Introduction

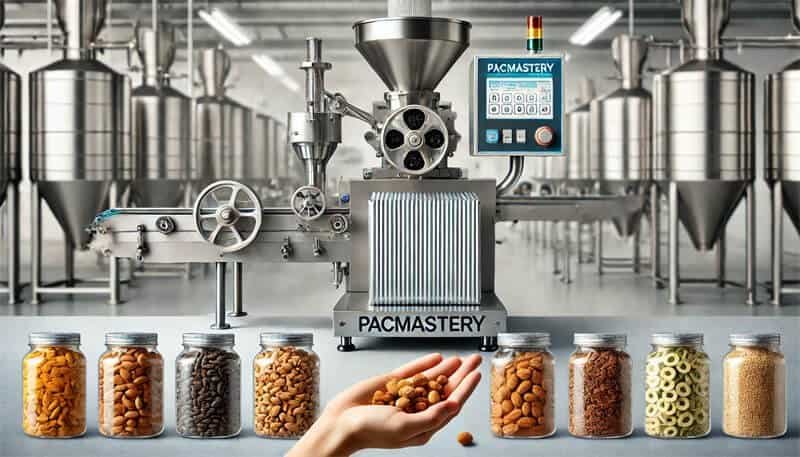

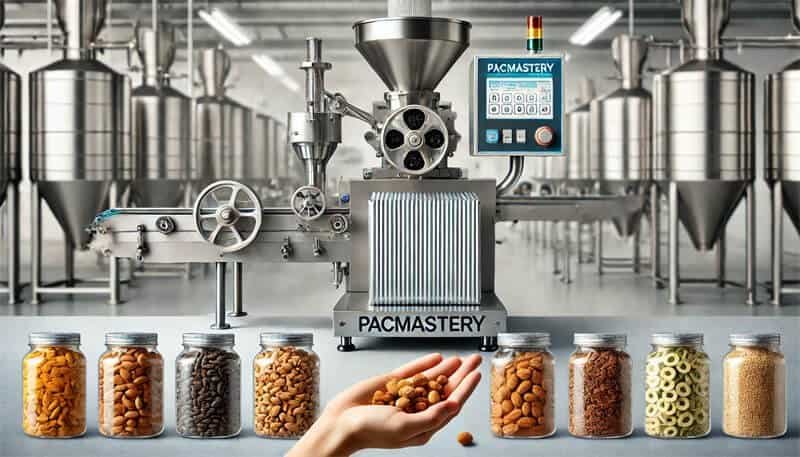

In today's fast-paced food industry, efficient and reliable packaging solutions are crucial for maintaining product quality, extending shelf life, and meeting consumer demands. Dry food packing machine manufacturers play a pivotal role in this ecosystem, providing cutting-edge technology and innovative solutions to food producers worldwide. This comprehensive guide will delve into the world of dry food packaging, exploring the latest trends, technologies, and key players in the industry.

The Importance of Dry Food Packaging

Dry foods, including snacks, cereals, grains, and pet food, require specialized packaging to maintain freshness, prevent contamination, and ensure product integrity. Proper packaging not only protects the food from external factors such as moisture, air, and light but also plays a crucial role in branding and consumer appeal. As such, the demand for high-quality, efficient dry food packing machines has never been higher.

Key Benefits of Advanced Dry Food Packaging Solutions

1. Extended shelf life

2. Improved product quality

3. Enhanced food safety

4. Reduced waste

5. Increased production efficiency

6. Better brand presentation

Types of Dry Food Packing Machines

Dry food packing machine manufacturers offer a wide range of equipment to cater to various packaging needs. Let's explore some of the most common types of machines used in the industry:

1. Vertical Form Fill Seal (VFFS) Machines

VFFS machines are among the most versatile and widely used packaging solutions in the dry food industry. These machines form a bag from a flat roll of film, fill it with the product, and seal it in a continuous process. VFFS machines are ideal for packaging a variety of dry foods, including snacks, grains, and powders.

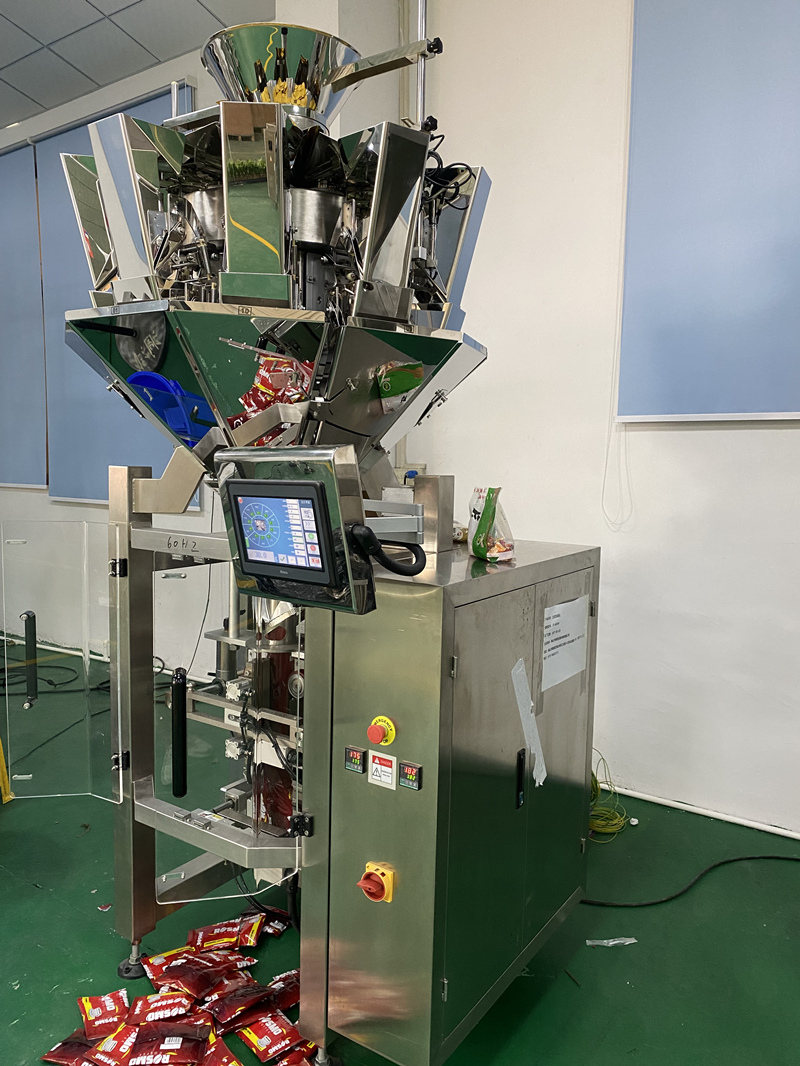

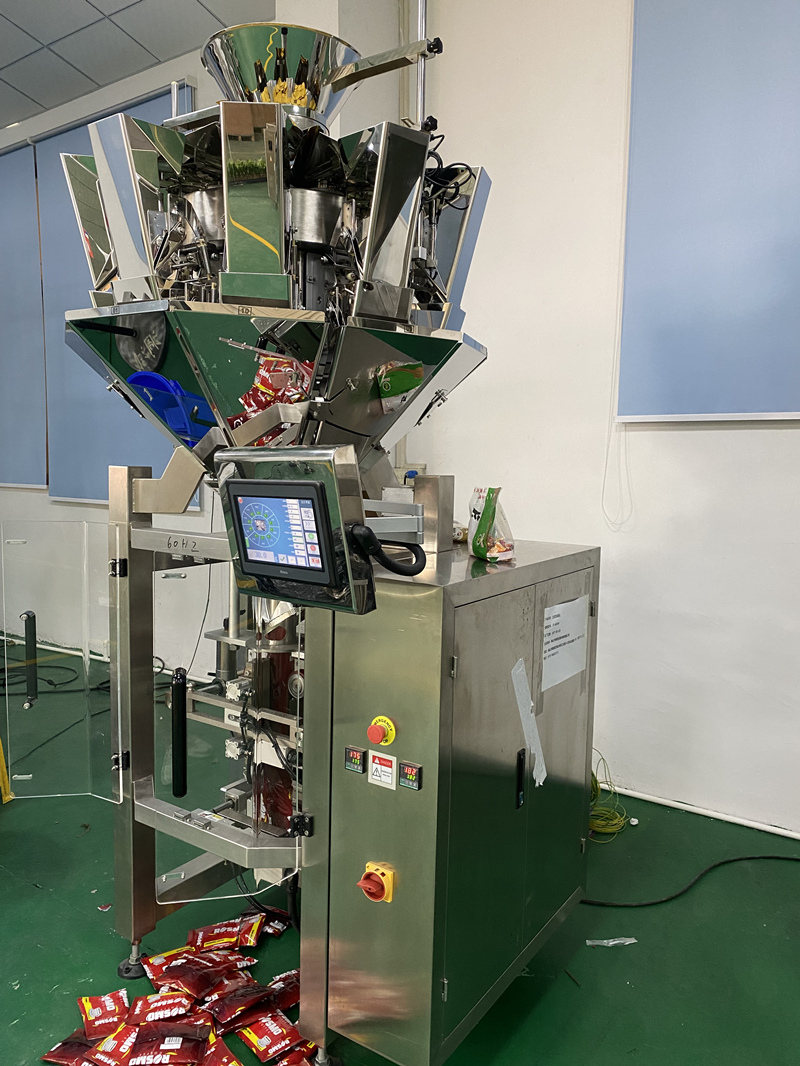

2. Multi-Head Weigher Packaging Systems

Multi-head weighers are essential components in many dry food packaging lines. These systems ensure accurate and consistent product weights, which is crucial for regulatory compliance and customer satisfaction. When combined with a packaging machine, multi-head weighers can significantly increase production speed and efficiency.

3. Vacuum Sealing Machines for Dry Foods

Vacuum sealing is an excellent method for preserving dry foods and extending their shelf life. Vacuum sealing machines remove air from the package before sealing, preventing oxidation and moisture ingress. These machines are particularly useful for packaging nuts, dried fruits, and other moisture-sensitive products.

4. Horizontal Flow Wrap Machines

Horizontal flow wrap machines are ideal for packaging individual items or small groups of products. These machines are commonly used for snack bars, cookies, and other portion-controlled dry food products. They offer high-speed packaging capabilities and can handle a wide range of package sizes and formats.

Advanced Features in Modern Dry Food Packaging Equipment

As technology continues to evolve, dry food packing machine manufacturers are incorporating advanced features to improve efficiency, flexibility, and product quality. Some of these cutting-edge features include:

1. Intelligent Control Systems

Modern packaging machines are equipped with sophisticated control systems that allow for precise adjustments and monitoring of the packaging process. These systems often include touchscreen interfaces, recipe management, and real-time performance data.

2. Servo-Driven Technology

Servo motors provide superior control and precision in packaging operations. They allow for faster changeovers, improved accuracy, and reduced maintenance requirements compared to traditional mechanical systems.

3. Integrated Vision Systems

Vision systems can detect defects, verify package integrity, and ensure proper labeling. These systems help maintain high quality standards and reduce the risk of product recalls.

4. Remote Monitoring and Diagnostics

Many modern packaging machines offer remote monitoring capabilities, allowing manufacturers to track performance, diagnose issues, and perform maintenance from anywhere in the world.

Choosing the Right Dry Food Packing Machine Manufacturer

Selecting the right dry food packing machine manufacturer is crucial for ensuring the success of your packaging operations. Here are some factors to consider when making your decision:

1. Experience and Reputation

Look for manufacturers with a proven track record in the dry food packaging industry. Consider their years of experience, customer testimonials, and industry recognition.

2. Range of Solutions

Choose a manufacturer that offers a wide range of packaging solutions to meet your specific needs. This includes various machine types, sizes, and customization options.

3. Innovation and Technology

Opt for manufacturers who invest in research and development and stay at the forefront of packaging technology. This ensures that you'll have access to the latest innovations and can remain competitive in the market.

4. After-Sales Support

Reliable technical support, spare parts availability, and comprehensive training programs are essential for maintaining your packaging equipment and maximizing its lifespan.

5. Compliance and Certifications

Ensure that the manufacturer's equipment meets all relevant industry standards and certifications, such as FDA, USDA, and CE marks.

The Future of Dry Food Packaging

The dry food packaging industry is constantly evolving, driven by changing consumer preferences, sustainability concerns, and technological advancements. Here are some trends shaping the future of dry food packaging:

1. Sustainable Packaging Solutions

Manufacturers are developing eco-friendly packaging materials and machines that can handle these materials efficiently. This includes biodegradable films, recyclable packaging, and reduced material usage.

2. Smart Packaging

The integration of smart technologies, such as NFC tags and QR codes, is enabling enhanced traceability, consumer engagement, and product authentication.

3. Flexible Packaging

The demand for flexible packaging continues to grow, driven by its convenience, cost-effectiveness, and reduced environmental impact compared to rigid packaging.

4. Automation and Industry 4.0

Increased automation and the adoption of Industry 4.0 principles are leading to more efficient, connected, and data-driven packaging operations.

Case Study: Implementing a High-Speed Packaging Line

To illustrate the impact of modern dry food packaging solutions, let's consider a case study of a snack food manufacturer that recently upgraded its packaging line:Company X, a leading producer of dried fruit and nut mixes, was facing challenges with its outdated packaging equipment. The company was struggling to meet increasing demand and maintain consistent product quality. After consulting with a reputable dry food packing machine manufacturer, they decided to invest in a new high-speed packaging line.The new line included:

- A multi-head weigher for accurate product dispensing

- A vertical form fill seal machine for primary packaging

- A robotic case packer for secondary packaging

- An integrated vision system for quality control

Results:

- 50% increase in production capacity

- 30% reduction in packaging material waste

- 99.9% accuracy in package weight

- Significant improvement in overall product quality and consistency

This case study demonstrates the transformative power of investing in modern packaging technology from a reliable dry food packing machine manufacturer.

Conclusion

The world of dry food packaging is dynamic and ever-evolving. By partnering with innovative dry food packing machine manufacturers, food producers can stay ahead of the curve, improve their operational efficiency, and deliver high-quality products to consumers. As we look to the future, the integration of sustainable materials, smart technologies, and advanced automation will continue to shape the industry, creating exciting opportunities for growth and innovation.

Frequently Asked Questions

1. What is the average lifespan of a dry food packing machine?

Answer: The lifespan of a dry food packing machine can vary depending on factors such as usage, maintenance, and build quality. On average, a well-maintained machine from a reputable manufacturer can last 10-15 years or more. Regular servicing and proper operation can significantly extend the machine's lifespan.

2. How do I determine the right packaging speed for my production line?

Answer: Determining the right packaging speed depends on several factors, including your production volume, product characteristics, and downstream processes. It's best to consult with a dry food packing machine manufacturer who can analyze your specific requirements and recommend a solution that balances speed with accuracy and product quality.

3. Can dry food packing machines handle different package sizes and formats?

Answer: Yes, many modern dry food packing machines are designed to be flexible and can handle multiple package sizes and formats. Look for machines with quick-change parts and recipe management systems that allow for easy changeovers between different products and package types.

4. What are the key maintenance requirements for dry food packaging equipment?

Answer: Regular maintenance is crucial for ensuring the longevity and performance of your packaging equipment. Key maintenance tasks include:

- Regular cleaning and sanitization

- Lubrication of moving parts

- Inspection and replacement of wear parts (e.g., sealing jaws, belts)

- Calibration of weighing and measuring systems

- Software updates and system checks

Always follow the manufacturer's recommended maintenance schedule and procedures.

5. How can I ensure my packaging line complies with food safety regulations?

Answer: To ensure compliance with food safety regulations:

- Choose equipment from reputable dry food packing machine manufacturers that meet industry standards and certifications

- Implement a robust cleaning and sanitation program

- Use food-grade materials and lubricants

- Conduct regular audits and inspections

- Train staff on proper hygiene and food safety practices

- Implement a traceability system

- Stay informed about the latest regulations and update your processes accordingly

By following these guidelines and working closely with your equipment manufacturer, you can maintain a high level of food safety compliance in your packaging operations.