Content Menu

● Understanding Kinkai Heat Pump Dryers

>> How Kinkai Heat Pump Dryers Work

● Advantages of Kinkai Heat Pump Dryers

● Energy Saving Features of Kinkai Heat Pump Dryers

>> 1. Recycling Heat

>> 2. Low Operating Costs

>> 3. Optimal Drying Conditions

● Applications of Kinkai Heat Pump Dryers in Food Processing

>> Expanded Applications

● Case Studies: Energy Savings with Kinkai Heat Pump Dryers

>> Case Study 1: Fruit Processing Facility

>> Case Study 2: Herb Production Company

>> Case Study 3: Seafood Processing Plant

● Technological Innovations in Kinkai Heat Pump Dryers

● Environmental Impact of Kinkai Heat Pump Dryers

● Conclusion

● FAQ

>> 1. What are Kinkai heat pump dryers?

>> 2. How do Kinkai heat pump dryers save energy?

>> 3. What types of food can be dried using Kinkai heat pump dryers?

>> 4. Are Kinkai heat pump dryers suitable for large-scale operations?

>> 5. How do I maintain a Kinkai heat pump dryer?

In the realm of food preservation, drying is a critical process that extends the shelf life of various products while retaining their nutritional value. Among the numerous technologies available for food drying, Kinkai heat pump dryers have emerged as a popular choice due to their energy efficiency and effectiveness. This article delves into the workings of Kinkai heat pump dryers, their advantages, and their role in energy-saving food drying processes.

Understanding Kinkai Heat Pump Dryers

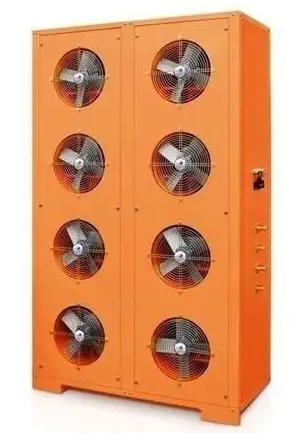

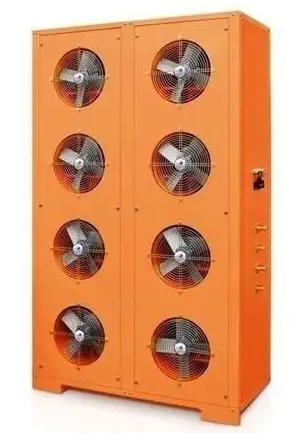

Kinkai heat pump dryers utilize a unique technology that harnesses ambient heat to dry food products. Unlike traditional drying methods that rely on direct heat sources, these dryers operate on a closed-loop system, which significantly reduces energy consumption.

How Kinkai Heat Pump Dryers Work

- Heat Absorption: The dryer absorbs heat from the surrounding environment.

- Heat Transfer: This absorbed heat is then transferred to the drying chamber where the food is placed.

- Moisture Removal: As the temperature rises, moisture evaporates from the food. The moisture-laden air is then expelled from the chamber.

- Condensation: The moisture is condensed back into water and removed, allowing for continuous drying.

This cycle repeats until the desired moisture content is achieved in the food product.

Advantages of Kinkai Heat Pump Dryers

Kinkai heat pump dryers offer several benefits over conventional drying methods:

- Energy Efficiency: These dryers can save up to 70% more energy compared to traditional electric or gas dryers.

- Temperature Control: They provide precise temperature control, ensuring that food retains its quality without being overcooked.

- Versatility: Suitable for a wide range of products including fruits, vegetables, herbs, and meats.

- Reduced Environmental Impact: Lower energy consumption translates to a smaller carbon footprint.

Energy Saving Features of Kinkai Heat Pump Dryers

The energy-saving capabilities of Kinkai heat pump dryers stem from several key features:

1. Recycling Heat

Kinkai dryers recycle heat within the system, which minimizes waste and maximizes efficiency. This feature allows them to operate at lower temperatures while still effectively removing moisture from food products.

2. Low Operating Costs

With reduced energy requirements, businesses can expect lower operating costs. This is particularly beneficial for large-scale operations where energy expenses can significantly impact overall profitability.

3. Optimal Drying Conditions

The ability to maintain optimal drying conditions not only preserves the quality of the food but also reduces the time required for drying. This efficiency means less energy used per batch of dried food.

Applications of Kinkai Heat Pump Dryers in Food Processing

Kinkai heat pump dryers find applications across various segments of the food processing industry:

- Fruit and Vegetable Drying: Ideal for preserving seasonal produce by removing moisture without compromising flavor or nutrients.

- Herb Drying: Maintains essential oils and flavors in herbs, making them more potent when used in culinary applications.

- Meat Drying: Effective for producing jerky or other dried meat products while ensuring safety through proper moisture removal.

- Seafood Drying: Provides an efficient method for drying fish and shellfish while retaining taste and texture.

Expanded Applications

In addition to these primary uses, Kinkai heat pump dryers are also effective in:

- Nut and Seed Drying: Preserving the quality and crunchiness of nuts and seeds while extending their shelf life.

- Specialty Foods: Such as flowers for culinary use or tea leaves that require careful moisture control to maintain flavor profiles.

Case Studies: Energy Savings with Kinkai Heat Pump Dryers

Several case studies highlight the effectiveness of Kinkai heat pump dryers in achieving significant energy savings:

Case Study 1: Fruit Processing Facility

A fruit processing facility switched from traditional drying methods to Kinkai heat pump dryers. They reported a reduction in energy consumption by approximately 65%, leading to annual savings of thousands of dollars. The facility also noted improved product quality due to better moisture control.

Case Study 2: Herb Production Company

A herb production company implemented Kinkai heat pump technology and noted not only lower energy bills but also improved product quality due to better temperature control during drying. The company was able to expand its product line with new dried herb offerings thanks to consistent results from their new equipment.

Case Study 3: Seafood Processing Plant

A seafood processing plant adopted Kinkai heat pump dryers for their shrimp drying operations. The plant achieved a remarkable 75% reduction in energy costs while enhancing the flavor retention in their dried shrimp products. This allowed them to market their products as premium offerings at higher price points.

Technological Innovations in Kinkai Heat Pump Dryers

Kinkai continues to innovate within its product line, integrating cutting-edge technology that enhances user experience and operational efficiency:

- Intelligent Control Systems: Many models come equipped with PLC (Programmable Logic Controller) systems that allow users to monitor and adjust settings remotely. This feature ensures optimal performance without constant supervision.

- Customizable Scheduling Software: Users can set specific drying schedules tailored to different products, maximizing efficiency and minimizing downtime between batches.

- Insulated Chambers: Advanced insulation techniques help maintain consistent temperatures within the drying chamber, reducing energy loss and improving overall efficiency.

Environmental Impact of Kinkai Heat Pump Dryers

The environmental benefits of using Kinkai heat pump dryers are significant:

- Reduced Carbon Footprint: By consuming less energy than traditional dryers, these machines contribute to lower greenhouse gas emissions associated with food processing.

- Sustainability Practices: Many businesses are adopting sustainable practices by utilizing equipment like Kinkai dryers that align with eco-friendly goals. This not only appeals to environmentally conscious consumers but also enhances brand reputation.

Conclusion

Kinkai heat pump dryers represent a revolutionary advancement in food drying technology. Their ability to save energy while maintaining high-quality standards makes them an excellent choice for businesses looking to enhance their production efficiency and sustainability. As industries continue to seek ways to reduce costs and environmental impact, Kinkai heat pump dryers stand out as a smart investment in modern food processing.

With their versatility across various applications—from fruits and vegetables to meats and seafood—these machines are well-equipped to meet diverse industry needs while promoting eco-friendly practices. As technology continues to evolve, so too will the capabilities of Kinkai heat pump dryers, ensuring they remain at the forefront of efficient food preservation solutions.

FAQ

1. What are Kinkai heat pump dryers?

Kinkai heat pump dryers are advanced drying machines that use ambient heat to dry food products efficiently while minimizing energy consumption.

2. How do Kinkai heat pump dryers save energy?

They save energy by recycling heat within the system and operating at lower temperatures compared to traditional dryers, which reduces overall power usage.

3. What types of food can be dried using Kinkai heat pump dryers?

They are versatile and can be used for drying fruits, vegetables, herbs, meats, seafood, nuts, seeds, and various other food items effectively.

4. Are Kinkai heat pump dryers suitable for large-scale operations?

Yes, they are designed for both small-scale and large-scale operations, providing significant energy savings and efficiency improvements across different production sizes.

5. How do I maintain a Kinkai heat pump dryer?

Regular maintenance involves cleaning filters, checking refrigerant levels, and ensuring that all components are functioning properly to maximize efficiency and prolong lifespan.