Content Menu

● Understanding Heat Pump Technology

● Efficiency Metrics

● Advantages of Using a Heat Pump Tumble Dryer

● Applications in Food Drying

● Components of a Heat Pump Tumble Dryer

● Comparing Heat Pump Dryers with Traditional Dryers

● Maintenance Tips for Heat Pump Dryers

● Real-Life Applications in Food Industry

● Conclusion

● FAQ

>> 1. What is the main advantage of using a heat pump tumble dryer?

>> 2. Can I use a heat pump dryer for food drying?

>> 3. How much energy does a typical 10kg heat pump dryer consume?

>> 4. What types of foods can be dried using this technology?

>> 5. How does moisture control work in these dryers?

● Citations:

In the world of modern appliances, heat pump dryers have emerged as a popular choice for both domestic and commercial settings, particularly for their energy efficiency and ability to handle large loads. This article delves into the efficiency of a 10kg heat pump dryer, exploring its design, functionality, and advantages, especially in the context of food drying applications.

Understanding Heat Pump Technology

Heat pump dryers operate using a closed-loop system that recycles air to dry clothes or food items. Unlike traditional dryers that expel hot air and draw in cold air, heat pump dryers use a refrigerant to absorb moisture from the air inside the drum. The process involves:

- Heating: The air is heated as it passes through a condenser.

- Absorption: Moist air is drawn from the drum and passed through an evaporator, where moisture is extracted.

- Recycling: The cooled, dry air is then reheated and recirculated back into the drum.

This method not only conserves energy but also allows for drying at lower temperatures, preserving the quality of sensitive materials like food products.

Efficiency Metrics

When assessing the efficiency of a 10kg heat pump tumble dryer, several factors come into play:

- Energy Consumption: Typically rated with high energy efficiency labels (A+++), these dryers can save up to 70% more energy compared to conventional dryers. For instance, a standard 10kg load might consume around 1.78 kWh per cycle.

- Drying Time: While drying times can vary based on load size and fabric type, a heat pump dryer usually takes longer than traditional models. However, this is offset by lower energy costs and better preservation of fabrics or food items.

- Moisture Control: Advanced sensors monitor moisture levels in real-time, adjusting drying times accordingly. This feature prevents over-drying and helps maintain the integrity of the items being dried.

Advantages of Using a Heat Pump Tumble Dryer

The benefits of using a heat pump tumble dryer extend beyond just energy savings:

- Versatility: Suitable for various applications including clothing and food drying. For food processing, it can effectively dry fruits, vegetables, meats, and herbs while retaining their nutrients.

- Environmentally Friendly: By reducing energy consumption and utilizing eco-friendly refrigerants, these dryers have a lower carbon footprint.

- Cost Efficiency: Although the initial investment may be higher than traditional dryers, the long-term savings on energy bills make them cost-effective over time.

- Low Noise Levels: Heat pump dryers tend to operate more quietly than conventional models due to their design. This makes them ideal for homes where noise can be an issue.

Applications in Food Drying

Heat pump technology is particularly beneficial in food drying processes. Here's how it works:

1. Preservation of Nutrients: Traditional drying methods often involve high temperatures that can degrade nutritional content. Heat pump dryers operate at lower temperatures (typically between 20°C to 80°C), preserving vitamins and minerals.

2. Quality Retention: The gentle drying process maintains the color, shape, and flavor of food items. This is crucial for businesses aiming to provide high-quality dried products.

3. Scalability: With models available that can handle up to 10kg or more per cycle, these dryers are ideal for both small-scale operations and larger commercial enterprises.

4. Efficiency in Operation: The ability to set specific humidity levels enhances control over the drying process, ensuring optimal results.

5. Reduced Risk of Spoilage: By providing consistent drying conditions, heat pump dryers minimize the risk of spoilage due to uneven moisture levels in food products.

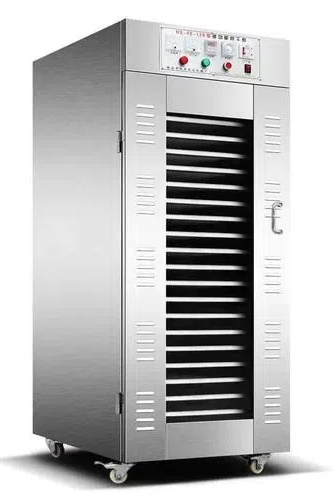

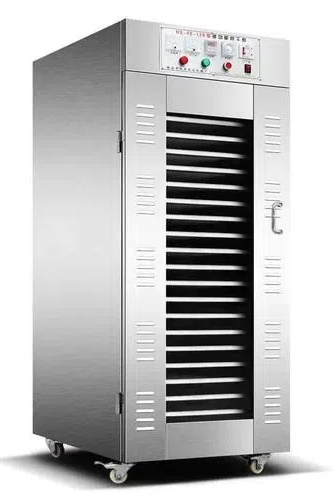

Components of a Heat Pump Tumble Dryer

Understanding the key components helps in appreciating how these machines work:

- Heat Pump Unit: The core component responsible for heating and cooling the air.

- Drum: Where items are placed for drying; designed for optimal airflow.

- Control System: Allows users to set drying times and monitor progress through digital displays.

- Filters: Essential for maintaining airflow efficiency; should be cleaned regularly to ensure optimal performance.

- Condensing Unit: This component collects moisture extracted from the air and condenses it into water droplets which are then drained away or collected in a tank.

Comparing Heat Pump Dryers with Traditional Dryers

To further understand the advantages of heat pump tumble dryers, let's compare them with traditional vented and condenser dryers:

| Feature | Heat Pump Dryer | Traditional Vented Dryer | Condenser Dryer |

| Energy Efficiency | High (A+++) | Low | Moderate |

| Drying Temperature | Low (20°C - 80°C) | High (up to 100°C) | Moderate |

| Moisture Control | Advanced sensors | Basic | Basic |

| Noise Level | Low | Moderate to High | Moderate |

| Initial Cost | Higher | Lower | Moderate |

| Operating Cost | Low | High | Moderate |

As illustrated in this comparison table, heat pump dryers stand out primarily due to their energy efficiency and lower operating costs over time.

Maintenance Tips for Heat Pump Dryers

To ensure optimal performance and longevity of your heat pump tumble dryer, consider these maintenance tips:

- Regular Cleaning: Clean lint filters after every use to maintain airflow efficiency. Also, periodically clean the condenser unit as per manufacturer guidelines.

- Check Drainage System: Ensure that any drainage hoses are clear and functioning properly to prevent water buildup inside the machine.

- Inspect Seals and Gaskets: Regularly check door seals and gaskets for wear or damage to maintain airtight conditions during operation.

- Professional Servicing: Schedule annual professional maintenance checks to ensure all components are functioning correctly and efficiently.

Real-Life Applications in Food Industry

Heat pump tumble dryers have found various applications in different sectors within the food industry:

1. Dried Fruits Production: Companies producing dried fruits benefit from heat pump technology as it allows them to retain natural sugars and flavors while ensuring uniform drying without burning or caramelizing.

2. Herb Drying: For culinary businesses focusing on herbs, these dryers provide an ideal solution that preserves essential oils and flavors better than traditional methods.

3. Meat Drying for Jerky Production: In jerky production facilities, maintaining low temperatures during drying is crucial for safety and quality; heat pump dryers excel in this area by providing controlled conditions that minimize bacterial growth while achieving desired textures.

4. Vegetable Chips Manufacturing: Producers of vegetable chips utilize heat pump technology to achieve crispiness without losing nutritional value or flavor integrity during processing.

5. Snack Food Companies: Many snack food manufacturers are adopting heat pump technology for their production lines due to its efficiency in maintaining product quality while reducing operational costs.

Conclusion

In conclusion, a 10kg heat pump tumble dryer is an efficient appliance that offers significant advantages in both home laundry applications and commercial food processing. Its ability to conserve energy while providing gentle yet effective drying makes it an excellent choice for those looking to reduce their environmental impact without compromising on quality.

With advancements in technology making these machines more user-friendly and versatile, investing in a heat pump dryer could be one of the best decisions for both domestic users and food manufacturers alike. As industries continue to evolve towards sustainability, heat pump technology represents a significant step forward in achieving energy-efficient solutions across various sectors.

FAQ

1. What is the main advantage of using a heat pump tumble dryer?

The main advantage is its energy efficiency; it uses less electricity compared to conventional dryers while providing effective drying at lower temperatures.

2. Can I use a heat pump dryer for food drying?

Yes! Heat pump dryers are excellent for food drying as they preserve nutrients better than traditional methods due to their low-temperature operation.

3. How much energy does a typical 10kg heat pump dryer consume?

A typical model consumes around 1.78 kWh per cycle when fully loaded, which is significantly less than traditional dryers.

4. What types of foods can be dried using this technology?

You can dry various foods including fruits, vegetables, meats, herbs, and even seafood effectively with heat pump technology.

5. How does moisture control work in these dryers?

Advanced sensors detect moisture levels within the drum and adjust drying times accordingly to prevent over-drying while ensuring items are thoroughly dried.

Citations:

[1] https://www.bxdrymachine.com/food-drying-machine.html

[2] https://www.webstaurantstore.com/guide/741/food-dehydrators-buying-guide.html

[3] https://pocketchangegourmet.com/how-does-a-dehydrator-work/

[4] https://industrialdryers.com/food-dryers/

[5] https://kerone.com/blog/drying-of-food/

[6] https://www.applianceshop.co.uk/hoover-ndeh10a2tcber-tumble-dryer-h-dry-500-10kg-heat-pump-dryer-wifi-graphi

[7] https://www.youtube.com/watch?v=rkrs5drN-AE

[8] https://www.youtube.com/watch?v=S-hDpODzIV0

[9] https://www.ikemachinery.com/food-drying-machine/

[10] https://etsolutions.in/how-does-a-food-dehydrator-work-explore-the-benefits-of-food-dehydrators/

[11] https://www.beko.ie/appliances/laundry/tumble-dryers/product/10kg-tumble-dryer-ironfinish-b5t41024i-white

[12] https://www.youtube.com/watch?v=sVXlslXKIag