Content Menu

● Understanding Food Drying

● What is a Heat Pump Dryer?

● What is a Condenser Dryer?

● Key Differences Between Heat Pump Dryers and Condenser Dryers

● Advantages of Heat Pump Dryers

● Disadvantages of Heat Pump Dryers

● Advantages of Condenser Dryers

● Disadvantages of Condenser Dryers

● Applications in Food Industry

● Choosing Between Heat Pump and Condenser Dryers

● Maintenance Considerations

● Future Trends in Food Drying Technology

● Conclusion

● FAQ

>> 1. What are the main benefits of using a heat pump dryer?

>> 2. Can I use a condenser dryer for all types of food?

>> 3. How do energy costs compare between heat pump and condenser dryers?

>> 4. Are there any specific foods that should not be dried using a condenser dryer?

>> 5. What factors should I consider when choosing between these two types of dryers?

In the world of food drying, understanding the technology behind different types of dryers is crucial for manufacturers, wholesalers, and brands. This article will delve into the differences between heat pump dryers and condenser dryers, specifically in the context of food drying machines. We will explore their mechanisms, advantages, disadvantages, and applications in the food industry.

Understanding Food Drying

Food drying is a preservation method that removes moisture from food to inhibit the growth of bacteria, yeasts, and molds. It enhances shelf life while retaining nutritional value and flavor. Various drying technologies exist, but heat pump and condenser dryers are among the most popular.

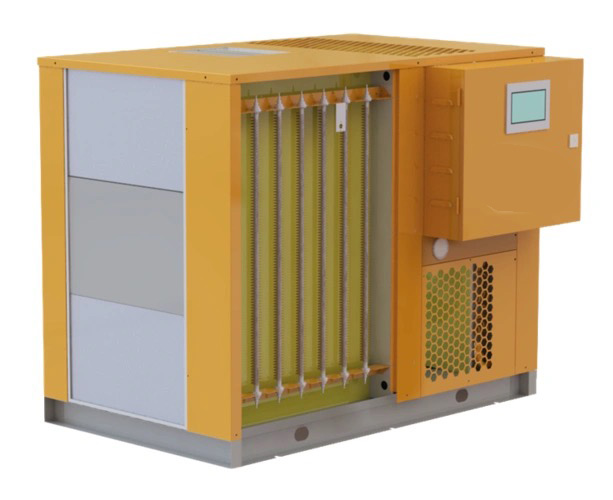

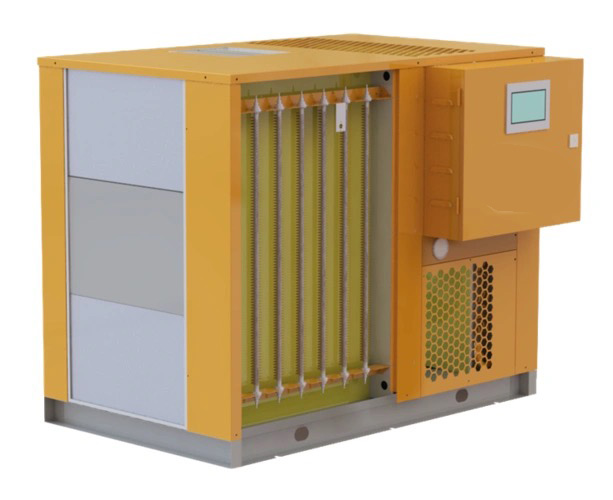

What is a Heat Pump Dryer?

A heat pump dryer utilizes a refrigeration cycle to transfer heat from one place to another. It consists of several components:

- Evaporator: Absorbs heat from the environment.

- Compressor: Increases the temperature of the absorbed heat.

- Condenser: Releases the heat into the drying chamber.

- Expansion Valve: Regulates refrigerant flow.

The cycle works by evaporating refrigerant at low temperatures in the evaporator, compressing it to increase its temperature, and then condensing it to release heat into the drying chamber. This process allows for efficient moisture removal at lower temperatures.

What is a Condenser Dryer?

A condenser dryer operates using a different principle. It also uses a refrigeration cycle but focuses on condensing moisture from the air inside the drying chamber. Key components include:

- Heating Element: Heats the air before it enters the drum.

- Drum: Where the food is placed for drying.

- Condenser: Cools down moist air to remove water vapor.

- Water Tank or Drainage System: Collects condensed water.

In a condenser dryer, warm air is circulated through the drum, absorbing moisture from the food. The moist air then passes through a condenser where it cools down, causing water vapor to condense into liquid form.

Key Differences Between Heat Pump Dryers and Condenser Dryers

| Feature | Heat Pump Dryer | Condenser Dryer |

| Energy Efficiency | Highly energy-efficient | Less energy-efficient compared to heat pump |

| Drying Temperature | Operates at lower temperatures | Higher temperatures used for drying |

| Moisture Removal Method | Uses a closed-loop system | Uses open-loop system |

| Installation | Requires more space due to additional components | More compact design |

| Cost | Generally higher upfront cost | Lower initial investment |

Advantages of Heat Pump Dryers

1. Energy Efficiency: Heat pump dryers are known for their low energy consumption due to their ability to recycle heat.

2. Gentle Drying Process: They operate at lower temperatures, making them suitable for delicate foods that require careful handling.

3. Consistent Results: The controlled environment ensures uniform drying without hot spots.

4. Eco-Friendly: Reduced energy consumption translates to a smaller carbon footprint.

5. Versatility: Heat pump dryers can be used for a wide range of products beyond just food, including textiles and wood.

6. Moisture Control: They maintain optimal humidity levels within the drying chamber, preventing over-drying or under-drying of products.

Disadvantages of Heat Pump Dryers

1. Higher Initial Cost: The technology involved can lead to higher purchase prices compared to condenser dryers.

2. Longer Drying Times: The lower temperatures can result in longer drying times for certain foods.

3. Complex Maintenance: The intricate components may require specialized knowledge for repairs and maintenance.

4. Size Constraints: Due to their design, they often require more space than traditional dryers.

Advantages of Condenser Dryers

1. Lower Initial Investment: Typically more affordable than heat pump dryers.

2. Faster Drying Times: Higher operating temperatures can lead to quicker drying processes.

3. Simpler Technology: Easier maintenance due to fewer complex components.

4. Compact Design: Ideal for facilities with limited space as they can fit into tighter areas compared to heat pump systems.

5. Immediate Use of Dried Products: The faster drying process allows for quicker turnaround times in production cycles.

Disadvantages of Condenser Dryers

1. Higher Energy Consumption: Less efficient than heat pump dryers, leading to higher operational costs over time.

2. Risk of Overheating: The use of high temperatures can damage sensitive foods if not monitored closely.

3. Limited Control Over Humidity: Less effective in managing humidity levels compared to heat pump systems.

4. Condensation Issues: If not properly maintained, condensation can lead to mold growth in the machine or surrounding areas.

5. Less Suitable for High-Value Products: For high-value items that require precise drying conditions, condenser dryers may not provide adequate control.

Applications in Food Industry

Both types of dryers have their unique applications in the food industry:

- Heat Pump Dryers

- Ideal for fruits, vegetables, herbs, and other delicate items that require gentle handling.

- Used in producing high-quality dried products with minimal nutrient loss.

- Suitable for products that need specific moisture content levels for optimal preservation.

- Employed in organic food processing where maintaining product integrity is crucial.

- Condenser Dryers

- Suitable for bulk drying operations where speed is essential.

- Often used for products like meats and fish that can withstand higher temperatures.

- Commonly found in commercial kitchens and food processing plants where efficiency is prioritized.

- Effective for dried pasta and grains where quick moisture removal is beneficial.

Choosing Between Heat Pump and Condenser Dryers

When deciding between a heat pump dryer and a condenser dryer for food processing, consider several factors:

- Type of Food Being Dried: Delicate foods may benefit from the gentle approach of heat pump dryers while bulkier items may do well in condenser dryers.

- Volume of Production: High-volume operations may prefer condenser dryers for their speed while smaller batches may be better suited for heat pumps due to their efficiency at lower volumes.

- Budget Constraints: Initial investment vs long-term energy savings should be evaluated carefully; while heat pumps may cost more upfront, they can save money over time through reduced energy bills.

- Space Availability: Consideration of installation space can influence your choice; if space is limited, a compact condenser dryer might be more appropriate than a larger heat pump model.

Maintenance Considerations

Proper maintenance is essential for both types of dryers to ensure longevity and efficiency:

- For heat pump dryers:

- Regularly check refrigerant levels and seals.

- Clean filters frequently to maintain airflow efficiency.

- Inspect electrical components periodically to prevent failures.

- For condenser dryers:

- Clean condensate trays and drainage systems regularly to prevent blockages.

- Monitor heating elements for wear and replace as necessary.

- Ensure proper ventilation around the unit to avoid overheating issues.

Future Trends in Food Drying Technology

As technology continues to evolve, both heat pump and condenser dryers are seeing advancements aimed at improving efficiency and user experience:

- Integration with IoT (Internet of Things) technology allows operators to monitor conditions remotely and adjust settings based on real-time data.

- Development of hybrid systems that combine features from both dryer types could offer enhanced flexibility in processing various food items efficiently.

- Innovations focusing on sustainability are leading manufacturers towards designing machines that consume less energy while maximizing output quality.

Conclusion

In summary, both heat pump dryers and condenser dryers have distinct advantages and disadvantages that cater to different needs within the food industry. Heat pump dryers offer energy efficiency and gentle drying processes ideal for sensitive foods, while condenser dryers provide faster drying times at a lower initial cost. Understanding these differences will help manufacturers make informed decisions about which technology best suits their production requirements.

FAQ

1. What are the main benefits of using a heat pump dryer?

Heat pump dryers are highly energy-efficient, operate at lower temperatures suitable for delicate foods, provide consistent results, and have an eco-friendly profile due to reduced energy consumption.

2. Can I use a condenser dryer for all types of food?

While you can use a condenser dryer for many types of food, it is less suitable for delicate items that may be damaged by higher temperatures compared to what heat pump dryers can offer.

3. How do energy costs compare between heat pump and condenser dryers?

Heat pump dryers are generally more energy-efficient than condenser dryers, leading to lower operational costs over time despite their higher initial purchase price.

4. Are there any specific foods that should not be dried using a condenser dryer?

Delicate foods such as certain fruits or herbs should be avoided in condenser dryers due to their risk of overheating; instead, heat pump dryers are recommended for these items.

5. What factors should I consider when choosing between these two types of dryers?

Considerations should include the type of food being dried, production volume requirements, budget constraints (initial investment vs long-term savings), and available installation space.