Content Menu

● Introduction

● Understanding Heat Pump Dryers

● The Drying Process

● Advantages of Heat Pump Dryers for Food Processing

● Applications in Food Industry

● Challenges and Considerations

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of using a heat pump dryer for food?

>> 2. How does a heat pump dryer compare to traditional drying methods?

>> 3. What types of food can be dried using a heat pump dryer?

>> 4. Are heat pump dryers energy-efficient?

>> 5. What are the common challenges faced when using heat pump dryers?

Introduction

In the modern food processing industry, the method of drying food is crucial for preserving quality, extending shelf life, and maintaining nutritional value. Among various drying technologies, heat pump dryers have emerged as a revolutionary solution. This article explores the drying effect of heat pump dryers, their advantages, applications in the food industry, and future trends.

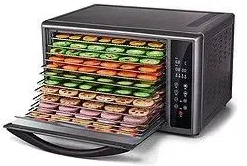

Understanding Heat Pump Dryers

Heat pump dryers utilize a refrigeration cycle to remove moisture from food products. Unlike traditional dryers that expel hot air, heat pump dryers recycle the air within the system, making them more energy-efficient. The process involves evaporating moisture from the food, which is then condensed and collected, allowing for continuous drying without significant energy loss.

The Drying Process

The drying cycle in a heat pump dryer consists of several stages:

1. Evaporation: Moisture from the food is evaporated using heat from the refrigerant.

2. Condensation: The vapor is then cooled, causing it to condense into water, which is collected.

3. Recycling: The remaining dry air is reheated and circulated back into the drying chamber.

This closed-loop system ensures optimal temperature and humidity control, which is essential for effective food drying.

Advantages of Heat Pump Dryers for Food Processing

Heat pump dryers offer numerous benefits for food processing:

1. Energy Efficiency: They consume significantly less energy compared to conventional dryers, leading to lower operational costs.

2. Quality Preservation: The gentle drying process helps retain the food's flavor, color, and nutritional content.

3. Environmental Impact: By reducing energy consumption, heat pump dryers contribute to lower greenhouse gas emissions.

Applications in Food Industry

Heat pump dryers are versatile and can be used for various food products, including fruits, vegetables, herbs, and meats. For instance, a case study involving the drying of apples demonstrated that heat pump technology preserved the fruit's natural sweetness and color better than traditional methods.

Challenges and Considerations

Despite their advantages, heat pump dryers do have limitations. They may require a longer drying time compared to conventional methods, and initial investment costs can be higher. When selecting a heat pump dryer, factors such as the type of food, desired moisture content, and production scale should be considered.

Future Trends in Food Drying Technology

The future of food drying technology is promising, with ongoing innovations in heat pump systems. Automation and smart technology integration are expected to enhance efficiency and user-friendliness, making heat pump dryers an even more attractive option for food processors.

Conclusion

Heat pump dryers represent a significant advancement in food drying technology, offering energy efficiency, quality preservation, and environmental benefits. As the food industry continues to evolve, the adoption of heat pump dryers is likely to increase, paving the way for more sustainable food processing practices.

Frequently Asked Questions

1. What is the main advantage of using a heat pump dryer for food?

The primary advantage is energy efficiency, which leads to cost savings and reduced environmental impact.

2. How does a heat pump dryer compare to traditional drying methods?

Heat pump dryers operate at lower temperatures and recycle air, making them gentler on food and more energy-efficient.

3. What types of food can be dried using a heat pump dryer?

Heat pump dryers are suitable for a wide range of foods, including fruits, vegetables, herbs, and meats.

4. Are heat pump dryers energy-efficient?

Yes, they are significantly more energy-efficient than traditional dryers, reducing operational costs.

5. What are the common challenges faced when using heat pump dryers?

Common challenges include longer drying times and higher initial investment costs.