Content Menu

● Introduction

● What is a Food Drying Machine?

>> Types of Food Drying Machines

● Why Choose a Sôlt Heat Pump Dryer?

>> Energy Efficiency

>> Consistent Quality

>> Versatility

>> Environmentally Friendly

● How Does a Solt Heat Pump Dryer Work?

● Applications of Solt Heat Pump Dryers

● Benefits of Using Sôlt Heat Pump Dryers

>> Enhanced Shelf Life

>> Improved Nutritional Value

>> Cost-Effectiveness

>> User-Friendly Design

● Technological Innovations in Food Drying Machines

>> Advanced Sensor Technology

>> Automation and Smart Controls

● Best Practices for Using Heat Pump Dryers

● Case Studies: Success Stories with Sôlt Heat Pump Dryers

>> Case Study 1: Organic Snack Producer

>> Case Study 2: Herbal Processing Facility

● Market Potential for Food Drying Machines

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What types of foods can be dried using a Solt Heat Pump Dryer?

>> 2. How does a heat pump dryer compare to traditional drying methods?

>> 3. What maintenance is required for a Solt Heat Pump Dryer?

>> 4. How long does it typically take to dry foods using this type of dryer?

>> 5. Can I use a Solt Heat Pump Dryer for commercial purposes?

Introduction

In the food processing industry, drying is a crucial step that enhances shelf life, preserves nutritional value, and maintains flavor. As demand for dried foods continues to rise globally, the need for efficient and reliable food drying machines has never been greater. Among the various options available, the Solt Heat Pump Dryer stands out as a leading choice for manufacturers and suppliers. This article explores the features, benefits, and applications of food drying machines, with a special focus on the Solt Heat Pump Dryer.

What is a Food Drying Machine?

A food drying machine is an appliance designed to remove moisture from food products. This process prevents spoilage and extends the shelf life of various items, including fruits, vegetables, meats, and herbs. The drying process typically involves heating the food to evaporate moisture while maintaining optimal temperature and airflow.

Types of Food Drying Machines

- Convection Dryers: Use hot air to circulate around the food.

- Freeze Dryers: Remove moisture by freezing the food and then applying a vacuum.

- Microwave Dryers: Utilize microwave radiation to heat and dry food quickly.

- Heat Pump Dryers: Use a heat pump system to efficiently remove moisture at lower temperatures.

Why Choose a Sôlt Heat Pump Dryer?

The Sôlt Heat Pump Dryer offers several advantages over traditional drying methods:

Energy Efficiency

The Solt Heat Pump Dryer operates at lower temperatures compared to conventional dryers. This not only saves energy but also helps in preserving the quality of the food being dried. By recycling heat within the system, it minimizes energy consumption significantly.

Consistent Quality

With precise temperature control and humidity management, the Solt Heat Pump Dryer ensures that food is dried evenly. This consistency helps maintain flavor, color, and nutritional value, making it an ideal choice for high-quality food products.

Versatility

The Sôlt Heat Pump Dryer can handle a wide variety of foods, including fruits, vegetables, meats, and even dairy products. This versatility makes it suitable for different applications in both small-scale and large-scale operations.

Environmentally Friendly

As businesses strive for sustainability, the Solt Heat Pump Dryer stands out due to its eco-friendly design. By using less energy and producing fewer emissions compared to traditional dryers, it aligns with modern environmental standards.

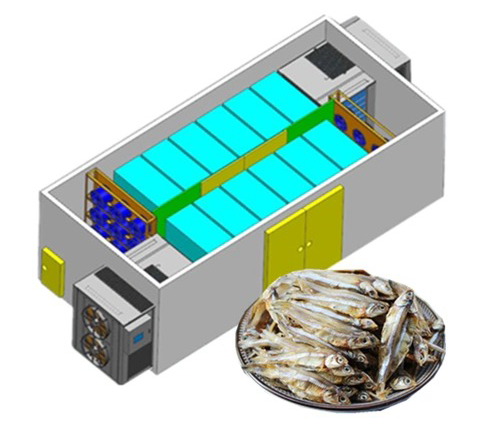

How Does a Solt Heat Pump Dryer Work?

The operation of a Solt Heat Pump Dryer can be broken down into several key steps:

1. Loading: The food is loaded onto trays within the drying chamber.

2. Heating: The heat pump generates warm air that circulates around the food.

3. Evaporation: Moisture evaporates from the surface of the food into the air.

4. Condensation: The moisture-laden air is passed through a condenser where it cools down, causing water vapor to condense back into liquid form.

5. Recycling: The heat generated during condensation is reused to heat incoming air, enhancing energy efficiency.

Applications of Solt Heat Pump Dryers

Sôlt Heat Pump Dryers are widely used in various sectors:

- Food Processing Plants: For large-scale drying of fruits and vegetables.

- Snack Manufacturers: To create healthy snacks from dehydrated fruits and vegetables.

- Herb Producers: For drying herbs while preserving their essential oils and flavors.

- Meat Processors: To produce jerky and other dried meat products.

Benefits of Using Sôlt Heat Pump Dryers

Enhanced Shelf Life

By effectively removing moisture from food products, Sôlt Heat Pump Dryers significantly extend their shelf life. This is particularly important for businesses looking to reduce waste and improve profitability.

Improved Nutritional Value

Unlike traditional drying methods that may use high temperatures that destroy nutrients, the lower temperatures used in Sôlt dryers help retain essential vitamins and minerals.

Cost-Effectiveness

While the initial investment in a Solt Heat Pump Dryer may be higher than conventional dryers, the long-term savings in energy costs and reduced waste make it a financially sound choice.

User-Friendly Design

Sôlt dryers are designed with user convenience in mind. Features such as digital controls, automatic timers, and easy-to-clean components make operation straightforward for users.

Technological Innovations in Food Drying Machines

The food drying industry has seen numerous technological advancements over the years, with the Solt Heat Pump Dryer being at the forefront. These innovations have focused primarily on improving efficiency, enhancing product quality, and reducing environmental impact.

Advanced Sensor Technology

Modern food drying machines, such as the Sôlt Heat Pump Dryer, are equipped with advanced sensors that provide precise control over humidity and temperature. These sensors ensure uniform drying by constantly assessing the conditions inside the drying chamber and adjusting accordingly. This technology minimizes the risk of over-drying or uneven drying, which can lead to inferior product quality.

Automation and Smart Controls

Incorporating smart technology into food drying machines allows operators to program drying cycles tailored to specific food types. The Solt Heat Pump Dryer includes features like programmable timers and remote monitoring capabilities. This level of automation not only improves operational efficiency but also reduces labor costs associated with manual monitoring.

Best Practices for Using Heat Pump Dryers

To maximize the benefits of using a Sôlt Heat Pump Dryer, it is essential to follow certain best practices during operation:

- Pre-treatment of Foods: Properly washing, peeling, and slicing foods can significantly improve drying efficiency. Smaller, uniform pieces dry more evenly and quickly.

- Optimal Loading: Avoid overcrowding trays. Ensuring adequate space allows for better air circulation and uniform drying.

- Regular Maintenance: Routine cleaning and inspection of the dryer help maintain its efficiency and extend its lifespan.

- Energy Monitoring: Utilize the dryer's energy settings to optimize power usage while maintaining drying quality.

Case Studies: Success Stories with Sôlt Heat Pump Dryers

Several businesses have successfully integrated Solt Heat Pump Dryers into their operations, yielding significant improvements in product quality and operational efficiency.

Case Study 1: Organic Snack Producer

An organic snack company replaced their conventional dryers with Sôlt Heat Pump Dryers and witnessed a 30% reduction in energy costs along with a 20% increase in production output. The advanced drying technology preserved the nutritional quality of their fruit chips, leading to greater customer satisfaction.

Case Study 2: Herbal Processing Facility

A herbal processing facility adopted Sôlt dryers to enhance the drying process of their medicinal herbs. The low-temperature drying capability allowed them to retain essential oils and active compounds, resulting in higher-quality herbal products that fetched premium prices on the market.

Market Potential for Food Drying Machines

With global emphasis on healthy eating and sustainable practices, the market potential for food drying machines like the Sôlt Heat Pump Dryer is immense. Here are a few trends driving demand:

- Rise of Health-Conscious Consumers: Increasing awareness of healthy eating habits has boosted demand for dried fruits, vegetables, and snacks.

- Sustainable Food Practices: As consumers and businesses strive for sustainability, energy-efficient dryers are becoming more appealing.

- Expanding Global Markets: Emerging markets in Asia, Africa, and Latin America are investing in food processing infrastructure—including drying technology—to meet growing demand.

- Diversified Applications: Beyond food processing, this technology is also being explored for drying pharmaceuticals, biofuels, and other industrial materials.

By embracing these technologies and trends, manufacturers and suppliers can capitalize on growing demand while expanding their market reach significantly.

Conclusion

The Sôlt Heat Pump Dryer represents an innovative solution in the realm of food drying technology. Its energy efficiency, consistent quality output, versatility across various food types, and environmentally friendly operation make it an excellent choice for businesses looking to improve their drying processes. By investing in advanced equipment like this one can enhance product quality while also achieving cost savings over time.

As you consider your options for food drying machines, keep in mind the numerous advantages offered by the Sôlt brand. Whether you are a manufacturer or supplier looking for OEM services or simply exploring ways to enhance your product line with high-quality dried foods, investing in a Solt Heat Pump Dryer could be one of your best decisions.

Frequently Asked Questions (FAQs)

1. What types of foods can be dried using a Solt Heat Pump Dryer?

You can dry various foods including fruits (like apples and bananas), vegetables (such as carrots and peppers), meats (for jerky), herbs (like basil and thyme), and even dairy products.

2. How does a heat pump dryer compare to traditional drying methods?

Heat pump dryers operate at lower temperatures which preserves more nutrients compared to traditional methods that often use higher temperatures. They are also more energy-efficient due to heat recycling capabilities.

3. What maintenance is required for a Solt Heat Pump Dryer?

Regular maintenance includes cleaning filters regularly checking seals for wear or damage ensuring proper airflow around the unit as well as periodic inspections of electrical components.

4. How long does it typically take to dry foods using this type of dryer?

Drying times vary based on type of food being dried along with its moisture content but generally range from several hours up to 24 hours for larger items or thicker cuts.

5. Can I use a Solt Heat Pump Dryer for commercial purposes?

Yes! The Solt Heat Pump Dryer is designed for both small-scale operations as well as large commercial applications due to its versatility and efficiency.