Content Menu

● Understanding Heat Pump Dryers

● How Heat Pump Dryers Work

● Advantages of Heat Pump Dryers

● Cost Savings Analysis

● Additional Financial Considerations

● Choosing the Right Food Dryer

● Applications in Food Processing

● Comparative Analysis with Other Drying Methods

● Conclusion

● FAQ

>> 1. What is a heat pump dryer?

>> 2. How much money can I save by switching to a heat pump dryer?

>> 3. Are heat pump dryers suitable for all types of food?

>> 4. Do I need special installation for a heat pump dryer?

>> 5. How do I maintain my heat pump dryer?

● Citations:

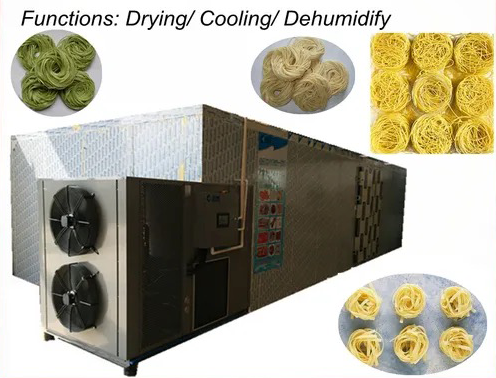

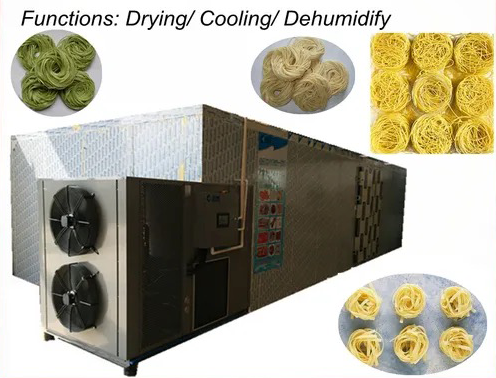

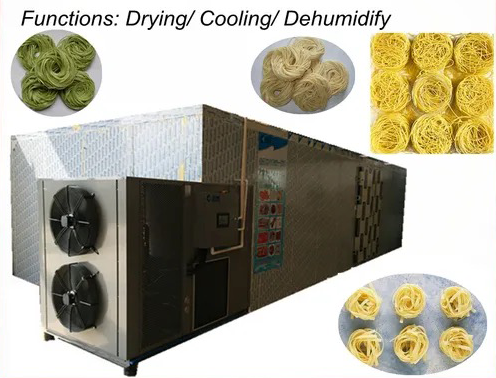

In recent years, the food processing industry has seen significant advancements in drying technology, particularly with the introduction of heat pump dryers. As a manufacturer of food drying machines, understanding the benefits and cost savings associated with these innovative devices is crucial for businesses looking to optimize their operations. This article explores how heat pump dryers work, their advantages over traditional drying methods, and the potential savings they offer.

Understanding Heat Pump Dryers

Heat pump dryers are a type of energy-efficient appliance that utilizes a heat exchange system to dry food products. Unlike conventional dryers that expel hot air and require constant heating, heat pump dryers recycle hot air within the unit. This not only conserves energy but also maintains a consistent drying temperature, which is essential for preserving the quality of food products.

How Heat Pump Dryers Work

Heat pump dryers operate on a simple principle: they extract moisture from the food by circulating warm air. The process involves several key components:

- Evaporator: Absorbs heat from the environment and cools down the air.

- Compressor: Increases the temperature of the absorbed heat, which is then circulated back into the drying chamber.

- Condenser: Removes moisture from the air, allowing it to be expelled or collected.

- Fan: Ensures even distribution of warm air throughout the drying chamber.

This closed-loop system allows heat pump dryers to use significantly less energy compared to traditional dryers, making them an attractive option for food manufacturers.

Advantages of Heat Pump Dryers

Switching to a heat pump dryer offers numerous benefits for food processing businesses:

- Energy Efficiency: Heat pump dryers can save up to 50% more energy than conventional electric dryers. This translates into substantial cost savings on energy bills over time.

- Consistent Quality: The ability to maintain a stable temperature ensures that food products are dried uniformly, preserving their flavor and nutritional value.

- Versatility: These dryers can handle various types of food products, including fruits, vegetables, meats, and herbs.

- Reduced Environmental Impact: By consuming less energy and producing fewer greenhouse gases, heat pump dryers contribute to more sustainable food processing practices.

- Lower Operating Costs: Besides energy savings, heat pump dryers often have lower maintenance costs due to their robust design and fewer moving parts compared to traditional dryers.

Cost Savings Analysis

To understand how much money a business can save by switching to a heat pump dryer, consider the following example:

Assuming a company operates its dryer for approximately 300 cycles per year and pays an average electricity rate of $0.12 per kWh:

- Traditional Electric Dryer Costs:

- Average cost per load: $0.53

- Total annual cost: 300 loads x 0.53 = $159

- Heat Pump Dryer Costs:

- Average cost per load: $0.30

- Total annual cost: 300 loads x 0.30 = $90

In this scenario, switching to a heat pump dryer could save the company approximately $69 annually in energy costs alone.

Additional Financial Considerations

When evaluating the financial implications of switching to a heat pump dryer, it's important to consider not just direct energy savings but also other factors such as:

- Initial Investment: While heat pump dryers may have a higher upfront cost compared to traditional models, their long-term savings often outweigh this initial investment.

- Increased Production Efficiency: With faster drying times and improved product quality, businesses may see an increase in production capacity and reduced waste.

- Government Incentives: Many regions offer incentives or rebates for businesses that invest in energy-efficient technologies. These can further offset initial costs.

Choosing the Right Food Dryer

When selecting a heat pump dryer for your food processing needs, consider factors such as:

- Capacity: Ensure that the dryer can handle your production volume.

- Temperature Control: Look for models with advanced temperature control systems for optimal drying results.

- Durability and Maintenance: Choose machines made from high-quality materials that require minimal maintenance.

- User-Friendly Features: Consider models with programmable settings and easy-to-read displays for enhanced usability.

Applications in Food Processing

Heat pump dryers are particularly beneficial in various sectors of food processing:

- Fruit Drying: They help retain the color and flavor of fruits while effectively removing moisture. This is especially important for products like apples, mangoes, and berries.

- Vegetable Drying: Vegetables can be dried without losing their nutritional value. Heat pump technology allows for gentle drying that preserves vitamins and minerals.

- Meat Drying: For products like jerky or dried meats, maintaining precise temperatures is crucial. Heat pump dryers provide consistent conditions that prevent spoilage.

- Herb Drying: Delicate herbs can be dried without losing their essential oils and flavors, making them ideal for culinary applications.

Comparative Analysis with Other Drying Methods

To further illustrate the advantages of heat pump dryers, let's compare them with other common drying methods:

| Feature | Heat Pump Dryer | Conventional Dryer | Solar Dryer |

| Energy Efficiency | High | Moderate | Variable |

| Initial Cost | Higher | Lower | Low |

| Operating Cost | Low | Moderate | Free (after setup) |

| Quality Preservation | Excellent | Good | Variable |

| Environmental Impact | Low | Moderate | Low |

This table highlights how heat pump dryers stand out in terms of energy efficiency and quality preservation compared to conventional methods while still being competitive against solar drying options in specific scenarios.

Conclusion

Switching to a heat pump dryer can lead to significant energy savings and improved product quality for food processing businesses. With their efficient operation and environmental benefits, these machines represent a smart investment for companies looking to enhance their drying processes while reducing costs.

As industries continue to seek sustainable solutions amid rising operational costs, adopting technologies like heat pump dryers will not only benefit individual businesses but also contribute positively to global sustainability efforts.

FAQ

1. What is a heat pump dryer?

A heat pump dryer is an energy-efficient appliance that uses a closed-loop system to recycle hot air for drying food products while consuming less energy compared to traditional dryers.

2. How much money can I save by switching to a heat pump dryer?

Businesses can save up to 50% on energy costs by switching from traditional electric dryers to heat pump dryers, depending on usage patterns and electricity rates.

3. Are heat pump dryers suitable for all types of food?

Yes, heat pump dryers are versatile and can effectively dry various types of food products including fruits, vegetables, meats, and herbs.

4. Do I need special installation for a heat pump dryer?

No, heat pump dryers do not require venting or duct installation like traditional dryers; they can be placed almost anywhere in your facility.

5. How do I maintain my heat pump dryer?

Regular maintenance includes cleaning filters, checking seals for leaks, and ensuring that the condenser is free from debris to maintain optimal performance.

Citations:

[1] https://aradmachineryco.com/article/Food-dehydrator-buying-guide

[2] https://topone-kitchen.com/news_41.html

[3] https://www.dryequipmfr.com/industrial-food-dryer-machine/

[4] https://www.friedmansappliance.com/blog/heat-pump-dryer

[5] https://acespace.org/blog/2023/04/06/save-on-an-electric-heat-pump-dryer/

[6] https://www.greenbuildingadvisor.com/article/heat-pump-clothes-dryers

[7] https://aradmachineryco.com/article/How-to-use-a-dehydratormachine

[8] http://repository.psa.edu.my/bitstream/123456789/2644/1/The%20Food%20Dehydrator.pdf

[9] https://fsdalle.en.made-in-china.com/product/XOGfuavVhtTF/China-OEM-ODM-Biltong-Dryer-Machine-Fruit-and-Vegetable-Dehydrator.html

[10] https://www.savemoneycutcarbon.com/learn-save/heat-pump-tumble-dryers-all-you-need-to-know/