Content Menu

● Introduction

● Understanding Food Dryers

>> The Role of Heat Pump Technology

● Cost Analysis of Running a Heat Pump Dryer

>> Initial Investment

>> Energy Consumption

>> Cost Per Load

>> Maintenance Costs

● Benefits of Using Heat Pump Dryers for Food Processing

>> Energy Efficiency

>> Quality Preservation

>> Versatility

>> Space Efficiency

>> Environmental Impact

● Conclusion

● Frequently Asked Questions

>> 1. What is the average cost of running a heat pump dryer?

>> 2. How long does it take to dry food in a heat pump dryer?

>> 3. Are heat pump dryers suitable for all types of food?

>> 4. What maintenance is required for heat pump dryers?

>> 5. Can heat pump dryers help reduce energy costs?

Introduction

In the world of food processing, drying is a crucial step that significantly impacts the quality, shelf life, and flavor of food products. As a leading manufacturer of food dryers in China, we specialize in providing OEM services to international brands, wholesalers, and producers. While our focus is on food drying technology, the principles of energy efficiency and cost-effectiveness are universal, much like those discussed in the context of heat pump dryers for laundry. This article will explore the intricacies of food dryers, particularly heat pump dryers, and how they can be a cost-effective solution for food processing.

Understanding Food Dryers

Food dryers, also known as dehydrators, are machines designed to remove moisture from food products. This process not only preserves the food but also enhances its flavor and nutritional value. There are various types of food dryers, including:

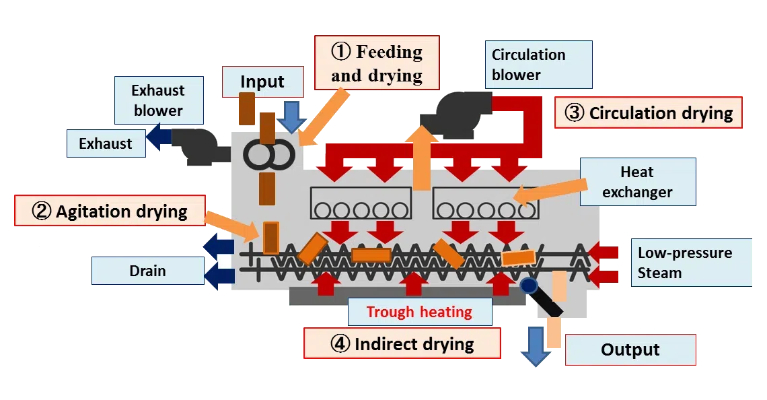

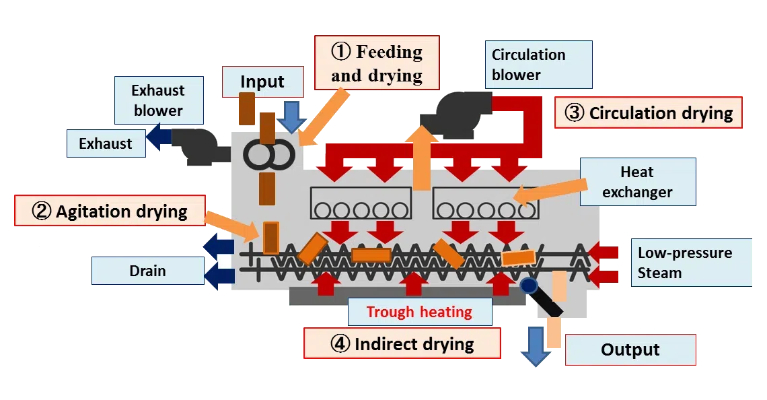

1. Conventional Dryers: These use direct heat to evaporate moisture.

2. Convection Dryers: These circulate hot air around the food to promote even drying.

3. Heat Pump Dryers: These utilize heat pump technology to efficiently remove moisture at lower temperatures.

The Role of Heat Pump Technology

Heat pump dryers are gaining popularity in the food processing industry due to their energy efficiency and ability to maintain the quality of the food being dried. Unlike conventional dryers that can use high temperatures, heat pump dryers operate at lower temperatures, which helps preserve the delicate flavors and nutrients in food.

Cost Analysis of Running a Heat Pump Dryer

Initial Investment

The initial cost of purchasing a heat pump dryer can be higher than that of conventional dryers. However, this investment is often offset by the long-term savings in energy costs. The efficiency of heat pump dryers means they use significantly less energy to operate, which can lead to substantial savings over time.

Energy Consumption

One of the most significant factors in determining the cost of running a heat pump dryer is its energy consumption. Heat pump dryers typically consume less energy than traditional dryers because they recycle heat within the system. This means that they can dry food products using less electricity, which is particularly beneficial for businesses that rely on large-scale food drying.

Cost Per Load

To understand the cost per load of running a heat pump dryer, we need to consider several factors:

1. Electricity Rates: The cost of electricity varies by region and can significantly impact the overall cost of running a dryer.

2. Drying Time: Heat pump dryers may take longer to dry food compared to conventional dryers, but the energy savings often compensate for this extended drying time.

3. Load Size: The amount of food being dried in each batch will also affect the cost per load. Larger loads can be more cost-effective as they maximize the use of the dryer’s capacity.

Maintenance Costs

Regular maintenance is essential for ensuring the longevity and efficiency of heat pump dryers. While maintenance costs can vary, they are generally lower than those for conventional dryers due to the robust design and fewer moving parts in heat pump systems. Proper maintenance can help prevent costly repairs and ensure optimal performance.

Benefits of Using Heat Pump Dryers for Food Processing

Energy Efficiency

Heat pump dryers are known for their energy efficiency. By using a closed-loop system to recycle heat, these dryers can reduce energy consumption by up to 70% compared to traditional drying methods. This efficiency not only lowers operational costs but also reduces the carbon footprint of food processing operations.

Quality Preservation

The lower drying temperatures used in heat pump dryers help preserve the quality of food products. This is particularly important for sensitive items like fruits, vegetables, and herbs, where high temperatures can lead to loss of flavor, color, and nutrients. The ability to maintain the integrity of the food being dried is a significant advantage for producers looking to offer high-quality products.

Versatility

Heat pump dryers can be used for a wide range of food products, making them a versatile choice for food processors. Whether you are drying fruits, vegetables, meats, or herbs, a heat pump dryer can handle various drying needs. This versatility allows businesses to diversify their product offerings and cater to different market demands.

Space Efficiency

Many heat pump dryers are designed to be compact and can fit into smaller spaces, making them ideal for businesses with limited floor space. This design allows for efficient use of space without compromising on drying capacity. For small to medium-sized enterprises, this can be a crucial factor in choosing the right drying equipment.

Environmental Impact

In addition to energy savings, heat pump dryers contribute to a more sustainable food processing operation. By reducing energy consumption and minimizing waste, these dryers help businesses lower their environmental impact. This is increasingly important as consumers become more environmentally conscious and prefer products from sustainable sources.

Conclusion

In conclusion, while the initial investment in a heat pump dryer may be higher than that of conventional dryers, the long-term savings in energy costs, combined with the benefits of quality preservation, versatility, and environmental impact, make them an excellent choice for food processing businesses. Understanding the cost per load and the factors that influence it can help businesses make informed decisions about their drying equipment.

Frequently Asked Questions

1. What is the average cost of running a heat pump dryer?

The average cost varies based on electricity rates and load size, but heat pump dryers are generally more cost-effective than conventional dryers.

2. How long does it take to dry food in a heat pump dryer?

Drying times can vary depending on the type of food and moisture content, but heat pump dryers typically take longer than conventional dryers.

3. Are heat pump dryers suitable for all types of food?

Yes, heat pump dryers can be used for a wide range of food products, including fruits, vegetables, meats, and herbs.

4. What maintenance is required for heat pump dryers?

Regular cleaning of filters and checking for any blockages are essential for maintaining efficiency and prolonging the life of the dryer.

5. Can heat pump dryers help reduce energy costs?

Yes, heat pump dryers are designed to be energy-efficient, often reducing energy consumption by up to 70% compared to traditional drying methods.