Content Menu

● Introduction

● Understanding Food Dryers

● How Heat Pump Dryers Work

● Key Components of a Heat Pump Dryer

● Cost of Running a Heat Pump Dryer

>> 1. Energy Consumption

>> 2. Initial Investment

>> 3. Maintenance Costs

>> 4. Operational Efficiency

>> 5. Labor Costs

● Benefits of Using Heat Pump Dryers

>> 1. Energy Efficiency

>> 2. Quality Preservation

>> 3. Versatility

>> 4. Reduced Waste

>> 5. Environmentally Friendly

● Comparing Heat Pump Dryers to Other Drying Methods

● Cost Comparison

● Efficiency Comparison

● Case Studies: Successful Implementation of Heat Pump Dryers

>> Case Study 1: Fruit Processing Facility

>> Case Study 2: Herb Drying Operation

● Conclusion

● Frequently Asked Questions

>> 1. What is the average cost of running a heat pump dryer?

>> 2. How long does it take to dry food using a heat pump dryer?

>> 3. Are heat pump dryers suitable for all types of food?

>> 4. What maintenance is required for heat pump dryers?

>> 5. Can heat pump dryers help reduce food waste?

Introduction

In the world of food processing, drying is a crucial step that significantly impacts the quality, shelf life, and flavor of food products. As a leading manufacturer of food dryers in China, we specialize in providing OEM services to international brands, wholesalers, and producers. While our focus is on food drying technology, the principles of energy efficiency and cost-effectiveness are universal, much like those found in heat pump dryers used for laundry. This article explores the intricacies of food dryers, particularly heat pump dryers, and delves into their operational costs, efficiency, and benefits.

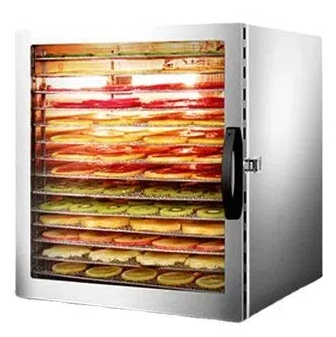

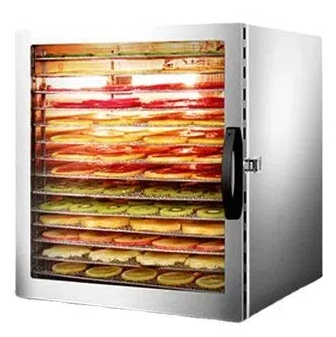

Understanding Food Dryers

Food dryers, also known as dehydrators, are machines designed to remove moisture from food products. This process not only preserves food but also enhances its flavor and nutritional value. There are various types of food dryers, including:

1. Convection Dryers: Use hot air to circulate around the food, removing moisture.

2. Freeze Dryers: Freeze the food and then remove moisture through sublimation.

3. Heat Pump Dryers: Utilize a heat pump system to efficiently dry food at lower temperatures.

Among these, heat pump dryers are gaining popularity due to their energy efficiency and ability to maintain the quality of the food being dried.

How Heat Pump Dryers Work

Heat pump dryers operate on the principle of transferring heat from one place to another. They use a refrigerant to absorb heat from the environment and transfer it to the food product. This method allows for lower drying temperatures, which helps preserve the food's flavor, color, and nutritional content.

Key Components of a Heat Pump Dryer

1. Evaporator: Absorbs heat from the air.

2. Compressor: Increases the temperature of the refrigerant.

3. Condenser: Releases heat to the drying chamber.

4. Expansion Valve: Regulates the flow of refrigerant.

Cost of Running a Heat Pump Dryer

When considering the operational costs of a heat pump dryer, several factors come into play:

1. Energy Consumption

Heat pump dryers are known for their low energy consumption compared to traditional dryers. They typically use less electricity because they operate at lower temperatures and recycle heat within the system. This efficiency translates to lower energy bills, making them an attractive option for food processing facilities.

2. Initial Investment

The initial cost of purchasing a heat pump dryer can be higher than that of conventional dryers. However, the long-term savings on energy costs often justify this investment. Businesses should consider the return on investment (ROI) when evaluating the cost-effectiveness of heat pump dryers.

3. Maintenance Costs

Regular maintenance is essential to keep heat pump dryers running efficiently. This includes cleaning filters, checking refrigerant levels, and ensuring that all components are functioning correctly. While maintenance costs are generally low, neglecting regular upkeep can lead to higher energy consumption and potential breakdowns.

4. Operational Efficiency

The efficiency of a heat pump dryer can significantly impact its running costs. Factors such as the type of food being dried, the moisture content, and the drying time all play a role in determining overall efficiency. Optimizing these variables can lead to substantial cost savings.

5. Labor Costs

While heat pump dryers automate much of the drying process, labor costs should also be considered. The need for skilled operators to monitor and manage the drying process can add to the overall cost. However, the automation capabilities of modern heat pump dryers can reduce the need for constant supervision.

Benefits of Using Heat Pump Dryers

1. Energy Efficiency

One of the most significant advantages of heat pump dryers is their energy efficiency. They can reduce energy consumption by up to 50% compared to traditional drying methods. This efficiency not only lowers operational costs but also minimizes the environmental impact of food processing.

2. Quality Preservation

Heat pump dryers operate at lower temperatures, which helps preserve the quality of the food. This is particularly important for sensitive products like fruits and vegetables, where high temperatures can lead to loss of flavor, color, and nutrients.

3. Versatility

Heat pump dryers can be used for a wide range of food products, including fruits, vegetables, meats, and herbs. This versatility makes them an excellent choice for food manufacturers looking to diversify their product offerings.

4. Reduced Waste

By effectively removing moisture, heat pump dryers help extend the shelf life of food products, reducing waste. This is especially beneficial in an industry where food spoilage can lead to significant financial losses.

5. Environmentally Friendly

With their lower energy consumption and reduced greenhouse gas emissions, heat pump dryers are an environmentally friendly option for food processing. Businesses that prioritize sustainability can benefit from using these efficient machines.

Comparing Heat Pump Dryers to Other Drying Methods

When evaluating the cost-effectiveness of heat pump dryers, it is essential to compare them with other drying methods. Traditional convection dryers, for instance, often operate at higher temperatures, which can lead to faster drying times but at the expense of energy efficiency and food quality. Freeze dryers, while excellent for preserving the integrity of food, can be significantly more expensive to operate and maintain.

Cost Comparison

1. Convection Dryers: Generally lower initial costs but higher energy consumption.

2. Freeze Dryers: High initial investment and operational costs, suitable for specific applications.

3. Heat Pump Dryers: Higher initial costs offset by lower energy consumption and better food quality preservation.

Efficiency Comparison

Heat pump dryers excel in efficiency, particularly for products that require gentle drying. Their ability to operate at lower temperatures means they can effectively dry delicate items without compromising their quality.

Case Studies: Successful Implementation of Heat Pump Dryers

Case Study 1: Fruit Processing Facility

A fruit processing facility implemented heat pump dryers to enhance their drying process. By switching from traditional convection dryers to heat pump technology, they reduced their energy costs by 40%. Additionally, the quality of their dried fruits improved, leading to higher customer satisfaction and increased sales.

Case Study 2: Herb Drying Operation

An herb drying operation faced challenges with maintaining the flavor and aroma of their products. After transitioning to heat pump dryers, they noticed a significant improvement in the quality of their dried herbs. The lower drying temperatures preserved essential oils, resulting in a premium product that commanded higher prices in the market.

Conclusion

In conclusion, while the initial investment in a heat pump dryer may be higher than that of traditional dryers, the long-term savings on energy costs, combined with the benefits of quality preservation and versatility, make them a worthwhile investment for food manufacturers. Understanding the operational costs and efficiency of these machines is crucial for making informed decisions in the food processing industry.

Frequently Asked Questions

1. What is the average cost of running a heat pump dryer?

The average cost varies based on energy prices and usage, but heat pump dryers are generally more cost-effective than traditional dryers.

2. How long does it take to dry food using a heat pump dryer?

Drying times can vary depending on the type of food and moisture content, but heat pump dryers typically take longer than conventional dryers due to their lower operating temperatures.

3. Are heat pump dryers suitable for all types of food?

Yes, heat pump dryers can effectively dry a wide range of food products, including fruits, vegetables, meats, and herbs.

4. What maintenance is required for heat pump dryers?

Regular maintenance includes cleaning filters, checking refrigerant levels, and ensuring all components are functioning properly.

5. Can heat pump dryers help reduce food waste?

Yes, by extending the shelf life of food products through effective moisture removal, heat pump dryers can significantly reduce food waste.