Content Menu

● Introduction

● The Science of Food Drying

● Heat Pump Technology Explained

● Applications of Heat Pump Dryers in Food Processing

● Advantages of Using Heat Pump Dryers

● Challenges and Considerations

● Future Trends in Food Drying Technology

● Conclusion

● Frequently Asked Questions

>> 1. What is the difference between heat pump drying and traditional drying methods?

>> 2. Can all types of food be dried using heat pump technology?

>> 3. What are the energy savings associated with heat pump dryers?

>> 4. How does heat pump technology preserve the quality of dried foods?

>> 5. What are the maintenance requirements for heat pump dryers?

Introduction

Food preservation has been a crucial aspect of human survival and culinary practices for centuries. Among various methods, drying stands out as one of the oldest and most effective techniques. In recent years, the advent of heat pump technology has revolutionized the food drying process, offering energy-efficient and sustainable solutions for both commercial and home applications. This article explores the science behind food drying, the workings of heat pump technology, and its advantages in preserving food quality.

The Science of Food Drying

Food drying is a process that removes moisture from food, inhibiting the growth of bacteria, yeasts, and molds that cause spoilage. The primary goal is to extend the shelf life of food while retaining its nutritional value. Traditional drying methods include sun drying, air drying, and smoking, but these can be time-consuming and less efficient.

Heat pump drying, on the other hand, utilizes a closed-loop system that circulates warm air to extract moisture from food. This method not only speeds up the drying process but also ensures a more consistent and controlled environment, which is crucial for preserving the quality of the food.

Heat Pump Technology Explained

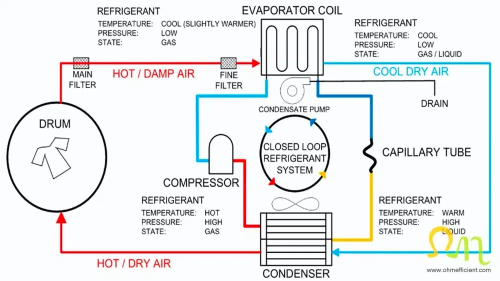

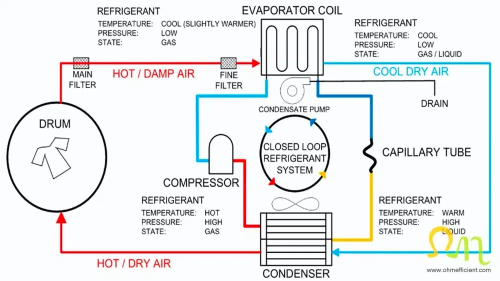

Heat pump dryers operate by transferring heat from one place to another, using a refrigerant to absorb and release heat. The process involves several key components: the evaporator, compressor, condenser, and expansion valve. The evaporator absorbs moisture from the food, while the compressor increases the temperature of the refrigerant. The condenser then releases the heat, drying the food effectively.

Compared to traditional drying methods, heat pump dryers are significantly more energy-efficient. They can save up to 70% more energy, making them an attractive option for businesses looking to reduce operational costs.

Applications of Heat Pump Dryers in Food Processing

Heat pump dryers are increasingly being adopted in commercial food processing due to their efficiency and effectiveness. They are particularly suitable for drying fruits, vegetables, and herbs, which require careful handling to maintain their quality.

For instance, a company specializing in dried fruits can utilize heat pump technology to ensure that their products retain their vibrant colors and flavors, appealing to health-conscious consumers. Case studies have shown that businesses using heat pump dryers report higher customer satisfaction and reduced waste due to spoilage.

Advantages of Using Heat Pump Dryers

The benefits of heat pump dryers extend beyond energy savings. They also offer significant environmental advantages by reducing greenhouse gas emissions associated with energy consumption. Additionally, the quality of dried foods is often superior, as the lower drying temperatures help preserve essential nutrients and flavors.

From an economic perspective, businesses can see a return on investment through reduced energy bills and increased product quality, leading to higher sales and customer loyalty.

Challenges and Considerations

Despite their advantages, heat pump dryers come with some challenges. The initial investment can be higher than traditional dryers, which may deter some businesses. Furthermore, proper maintenance is essential to ensure optimal performance, including regular cleaning and checks on the refrigerant levels.

Future Trends in Food Drying Technology

As technology continues to evolve, the future of food drying looks promising. Innovations in heat pump technology, such as improved energy efficiency and automation, are on the horizon. Smart technology integration will allow for better monitoring and control of the drying process, ensuring consistent quality and efficiency.

Conclusion

Heat pump technology represents a significant advancement in the field of food drying. By offering energy-efficient solutions that preserve food quality, heat pump dryers are becoming an essential tool for food processors. As the demand for sustainable practices grows, the adoption of heat pump technology in food drying will likely increase, benefiting both businesses and consumers alike.

Frequently Asked Questions

1. What is the difference between heat pump drying and traditional drying methods?

Heat pump drying uses a closed-loop system to recycle heat, making it more energy-efficient compared to traditional methods that often lose heat to the environment.

2. Can all types of food be dried using heat pump technology?

While many foods can be dried using heat pump technology, it is particularly effective for fruits, vegetables, and herbs. Some foods may require specific conditions for optimal drying.

3. What are the energy savings associated with heat pump dryers?

Heat pump dryers can save up to 70% more energy compared to conventional dryers, leading to significant cost savings over time.

4. How does heat pump technology preserve the quality of dried foods?

Heat pump technology operates at lower temperatures, which helps retain the nutritional value, flavor, and color of the food being dried.

5. What are the maintenance requirements for heat pump dryers?

Regular cleaning of filters and ensuring proper airflow are essential for maintaining efficiency. Additionally, periodic checks on the refrigerant levels may be necessary.