Content Menu

● What Are Room Type Drying Machines?

>> Key Features of Room Type Drying Machines

● How Do Room Type Drying Machines Save Energy?

>> 1. Heat Pump Technology

>> 2. Insulated Chambers

>> 3. Moisture Removal Systems

>> 4. Digital Control Panels

>> 5. Batch Drying Efficiency

● Benefits of Room Type Drying Machines

>> 1. Cost Savings

>> 2. Environmental Sustainability

>> 3. Enhanced Food Quality

>> 4. Versatility

● Applications of Room Type Drying Machines

>> Fruit Drying

>> Vegetable Drying

>> Meat Processing

>> Seafood Preservation

>> Grain Storage

● Advanced Features of Room Type Drying Machines

>> Intelligent Control Systems

>> Multi-stage Drying Programs

>> Remote Monitoring and Control

>> Energy Recovery Systems

● Choosing the Right Room Type Drying Machine

● Future Trends in Room Type Drying Machines

● Conclusion

● FAQs About Room Type Drying Machines

>> 1. How do room type drying machines reduce energy consumption?

>> 2. What types of food can be dried using these machines?

>> 3. Are room type drying machines environmentally friendly?

>> 4. Can these machines handle large-scale production?

>> 5. How do I maintain a room type drying machine?

● Citations:

Room type drying machines have revolutionized the food processing industry by offering energy-efficient solutions for drying various food products. These machines cater to industries requiring large-scale drying operations, such as fruits, vegetables, meat, seafood, and grains. In this article, we will explore how room type drying machines save energy, their working principles, and their benefits for businesses.

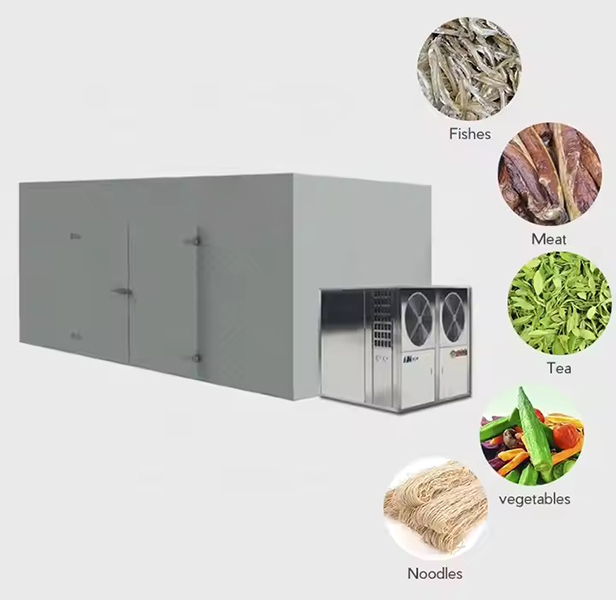

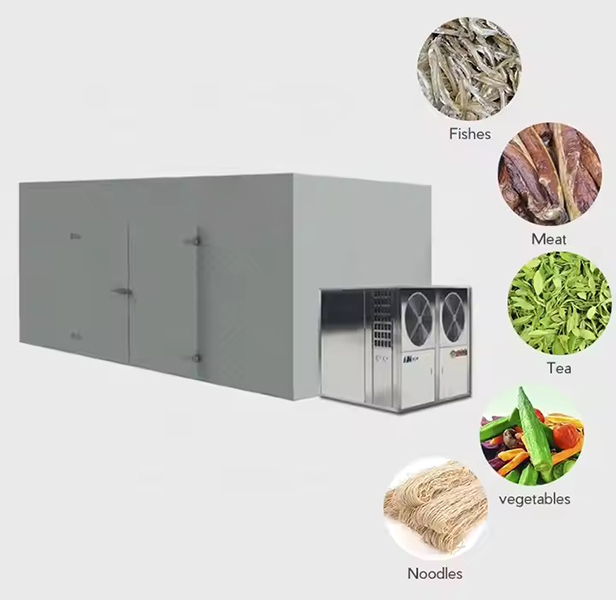

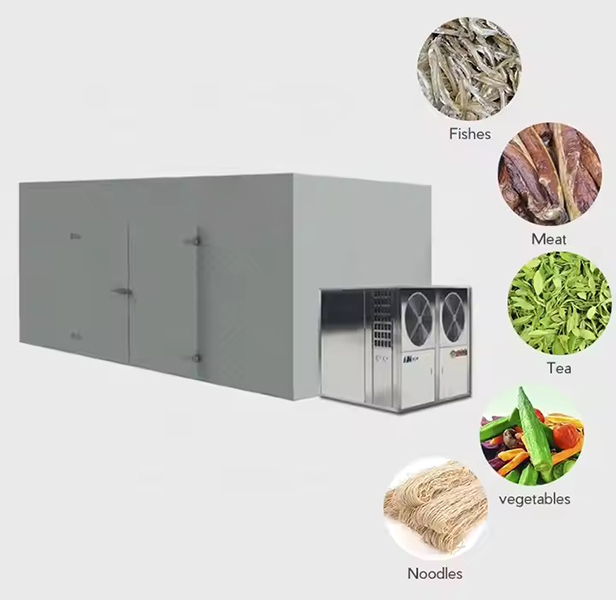

What Are Room Type Drying Machines?

Room type drying machines are advanced food dehydrators designed to dry large quantities of food in a controlled environment. These machines utilize heat pump technology, insulated chambers, and precise control systems to optimize the drying process while minimizing energy consumption.

Key Features of Room Type Drying Machines

- Energy Efficiency: They save up to 75% energy compared to conventional dryers by recycling heat during the drying process.

- Customizable Capacity: Ranging from 1,000 kg to 100 tons, these machines can be tailored to meet specific production needs.

- Temperature Control: Adjustable temperature settings from 18°C to 80°C allow for both high and low-temperature drying.

- Food-Grade Materials: Made with SS304 stainless steel trays and racks for safety and durability.

How Do Room Type Drying Machines Save Energy?

1. Heat Pump Technology

Heat pump technology is at the core of energy savings in room type drying machines. This system recycles heat generated during the drying process, reducing the need for additional energy input. The heat pump captures excess heat and reuses it to maintain optimal drying conditions.

2. Insulated Chambers

The chambers are constructed with polyurethane insulation boards that retain heat effectively. This minimizes energy loss and ensures a consistent temperature throughout the drying process.

3. Moisture Removal Systems

Advanced dehumidification systems remove moisture-laden air efficiently, reducing the overall drying time and energy usage. By maintaining optimal humidity levels, these systems prevent over-drying and unnecessary energy expenditure.

4. Digital Control Panels

User-friendly digital panels allow precise adjustments of temperature, airflow, and humidity. This precision ensures that only the required amount of energy is used during the drying cycle.

5. Batch Drying Efficiency

Room type drying machines are designed for batch processing, enabling businesses to dry large quantities of food in one cycle. This reduces operational costs and enhances productivity while saving energy.

Benefits of Room Type Drying Machines

1. Cost Savings

By consuming only 25% of the electricity used by traditional dryers, room type drying machines significantly lower operational costs. This translates to substantial savings on energy bills, making them a cost-effective investment for food processing businesses.

2. Environmental Sustainability

The reduced energy consumption translates into a smaller carbon footprint, making these machines an eco-friendly choice for businesses. By opting for room type drying machines, companies can significantly reduce their environmental impact and contribute to global sustainability efforts.

3. Enhanced Food Quality

Precise temperature and humidity control ensure that food retains its nutritional value, flavor, and texture during the drying process. This results in high-quality dried products that meet consumer expectations and industry standards.

4. Versatility

These machines can handle a wide range of food products, including fruits, vegetables, meat, seafood, grains, and dairy products. This versatility makes them suitable for various food processing applications, allowing businesses to diversify their product offerings.

Applications of Room Type Drying Machines

Room type drying machines are widely used in various industries:

Fruit Drying

Room type drying machines excel in preserving fruits while maintaining their nutritional value and flavor. Popular applications include:

- Apples: Creating crisp apple chips

- Bananas: Producing chewy banana slices

- Mangoes: Crafting sweet dried mango pieces

Vegetable Drying

These machines are ideal for dehydrating vegetables, ensuring long shelf life and concentrated flavors:

- Tomatoes: Making sun-dried tomatoes

- Onions: Creating dried onion flakes

- Peppers: Producing dried bell pepper strips

Meat Processing

Room type drying machines play a crucial role in meat preservation:

- Jerky production: Creating various flavored beef, pork, or poultry jerky

- Sausage curing: Drying and curing traditional sausages

Seafood Preservation

The machines are excellent for preserving seafood products:

- Fish: Drying fish fillets for long-term storage

- Shrimp: Creating dried shrimp for snacks or cooking ingredients

Grain Storage

Room type drying machines are essential in the grain industry:

- Rice: Drying freshly harvested rice to prevent spoilage

- Wheat: Reducing moisture content in wheat for safe storage

Advanced Features of Room Type Drying Machines

Intelligent Control Systems

Modern room type drying machines are equipped with intelligent control systems that optimize the drying process based on the specific characteristics of each food product. These systems use sensors to monitor temperature, humidity, and air circulation, adjusting parameters in real-time to achieve the best results while minimizing energy consumption.

Multi-stage Drying Programs

To cater to different food types and desired outcomes, room type drying machines often feature multi-stage drying programs. These programs allow for varying temperature and humidity levels throughout the drying cycle, ensuring optimal results for complex drying requirements.

Remote Monitoring and Control

Many advanced models now offer remote monitoring and control capabilities. This feature allows operators to monitor the drying process, adjust settings, and receive alerts via smartphone apps or computer interfaces, enhancing operational efficiency and reducing the need for constant on-site supervision.

Energy Recovery Systems

Some high-end room type drying machines incorporate additional energy recovery systems. These systems capture and utilize waste heat from other processes in the facility, further reducing overall energy consumption and improving sustainability.

Choosing the Right Room Type Drying Machine

When selecting a room type drying machine for your business, consider the following factors:

1. Production Capacity: Assess your current and future production needs to choose a machine with appropriate capacity.

2. Energy Efficiency Ratings: Look for machines with high energy efficiency ratings to maximize cost savings and environmental benefits.

3. Temperature Range: Ensure the machine's temperature range is suitable for the types of food products you plan to dry.

4. Control Features: Opt for machines with advanced control systems that offer precise adjustments and easy operation.

5. Material Quality: Choose machines made with food-grade materials to ensure product safety and longevity of the equipment.

6. Maintenance Requirements: Consider the ease of cleaning and maintenance to minimize downtime and operational costs.

7. Manufacturer Reputation: Select machines from reputable manufacturers with a track record of quality and customer support.

Future Trends in Room Type Drying Machines

As technology continues to advance, we can expect to see further improvements in room type drying machines:

- AI-powered Optimization: Integration of artificial intelligence to further optimize drying processes based on historical data and product characteristics.

- IoT Integration: Enhanced connectivity and data collection capabilities through Internet of Things (IoT) technology, allowing for better process tracking and predictive maintenance.

- Renewable Energy Integration: Development of hybrid systems that can utilize renewable energy sources like solar or wind power to supplement electricity usage.

- Modular Designs: Creation of modular room type drying machines that can be easily scaled up or down based on production needs.

Conclusion

Room type drying machines offer an innovative solution for efficient food dehydration while significantly reducing energy consumption. Their advanced features—such as heat pump technology, insulated chambers, and precise control systems—make them indispensable for businesses aiming to enhance productivity while minimizing costs.

By adopting room type drying machines, companies not only save on operational expenses but also contribute to environmental sustainability by lowering their carbon footprint. As the food processing industry continues to evolve, these energy-efficient machines will play an increasingly important role in meeting the growing demand for dried food products while adhering to sustainability goals.

FAQs About Room Type Drying Machines

1. How do room type drying machines reduce energy consumption?

Room type drying machines use heat pump technology to recycle heat generated during the drying process. This reduces the need for additional heating and minimizes energy usage.

2. What types of food can be dried using these machines?

These machines are versatile and can dry fruits, vegetables, meat, seafood, grains, and even dairy products like cheese.

3. Are room type drying machines environmentally friendly?

Yes, they are eco-friendly due to their high energy efficiency and ability to reduce carbon emissions through lower electricity consumption.

4. Can these machines handle large-scale production?

Absolutely! With capacities ranging from 1 ton to 100 tons per batch, they are ideal for industrial-scale operations.

5. How do I maintain a room type drying machine?

Regular cleaning of trays and fans ensures optimal airflow and efficiency. Periodic maintenance checks on heating systems and control panels are also recommended.

Citations:

[1] https://www.dryeratech.com/room-type-drying-machine.html

[2] https://septree.com/blogs/news/energy-consumption-of-food-dehydrators-what-you-need-to-know

[3] https://tunelgroup.com/drying-rooms-in-the-food-industry-essential-technology-for-long-term-food-storage/

[4] https://www.aimheatpump.com/video/a-products-aim-heat-pump-food-drying-machine-large-capacity-energy-efficient

[5] https://www.aimheatpump.com/video/a-products-aim-heat-pump-food-drying-machine-high-capacity-separated-dryer

[6] https://www.aimheatpump.com/video/a-products-heat-pump-food-drying-machine-efficient-and-easy

[7] https://www.youtube.com/watch?v=UnRHXQ48L7I

[8] https://www.jimdry.com/room-type-stacked-dryer.html

[9] https://www.dryeratech.com/hang-type-drying-machines-the-eco-friendly-drying-solution.html

[10] https://www.helperfoodmachine.com/food-drying-room/

[11] https://www.linkedin.com/pulse/drying-rooms-benefits-purpose-humiscope

[12] https://www.vegemachine.com/dry/food-heat-pump-drying-machine.html

[13] https://www.pinterest.com/smallkitchenap2/dehydrators/

[14] https://www.shutterstock.com/search/dehydrator-machine

[15] https://www.dehydratorsamerica.com/category/industrial-food-dehydrators

[16] https://www.linkedin.com/pulse/case-study-dry-aging-benefits-drying-room-humiscope

[17] https://www.seriouseats.com/best-food-dehydrators-5216308

[18] https://www.youtube.com/watch?v=Ny6tGbu2nQ0

[19] https://www.aimheatpump.com/products-25587

[20] https://www.youtube.com/watch?v=Namf-Ddo_Xo