Content Menu

● Understanding Hang-Type Drying Machines

>> Key Features of Hang-Type Drying Machines

● The Science Behind Hang-Type Drying

>> Energy Efficiency and Heat Pump Technology

>> Importance of Humidity Control

● Optimizing the Drying Process

>> 1. Initial Moisture Content

>> 2. Particle Size and Shape

>> 3. Airflow Management

>> 4. Insulation Quality

>> 5. Automation and Control Systems

● Steps in the Hang-Type Drying Process

● Common Challenges in Hang-Type Drying

>> Uneven Drying

>> Over-Drying or Under-Drying

>> Maintenance Requirements

● Best Practices for Successful Hang-Type Drying

>> Regular Calibration

>> Pre-Drying Preparation

>> Monitoring During Operation

>> Documentation and Feedback Loop

● Conclusion

● FAQ

>> 1. What types of food products can be dried using hang-type machines?

>> 2. How does heat pump technology improve energy efficiency?

>> 3. What is the ideal temperature range for drying food?

>> 4. Can automation enhance the drying process?

>> 5. How does particle size affect drying efficiency?

● Citations:

Understanding Hang-Type Drying Machines

Hang-type drying machines operate by creating a controlled environment where moisture is gradually removed from food items. This method is particularly effective for products such as noodles, sausages, and various types of fish. The design of these machines allows for uniform drying, which is crucial for preserving texture and flavor.

Key Features of Hang-Type Drying Machines

1. Food Grade Materials: Constructed from high-quality stainless steel, ensuring compliance with hygiene standards.

2. Capacity Options: Available in various sizes, from small units for artisanal production to large-scale industrial processors.

3. Energy Efficiency: Utilizing heat pump technology can save up to 75% on energy costs compared to traditional methods.

4. Adjustable Temperature: A temperature range of 18-80℃ allows for precise control over the drying process.

5. Intelligent Digital Control: User-friendly systems enable easy programming and monitoring.

The Science Behind Hang-Type Drying

The efficiency of hang-type drying machines relies on forced convection. Fans create a continuous airflow that carries away evaporated moisture, significantly speeding up the drying process compared to natural convection methods.

Energy Efficiency and Heat Pump Technology

Heat pump dryers are an advanced type of hang-type machine that recycles heat from exhaust air, reducing energy consumption. There are three main types:

- Open-Loop Heat Pump Dryers: Draw fresh air from the environment.

- Closed-Loop Heat Pump Dryers: Recirculate air within the chamber.

- Open/Closed-Loop Heat Pump Dryers: Combine both methods for flexibility.

Importance of Humidity Control

Humidity control is vital in the hang-type drying process. High humidity levels can slow down moisture removal and lead to uneven drying. Monitoring humidity levels with sensors can help maintain optimal conditions throughout the drying cycle.

Optimizing the Drying Process

To maximize efficiency in hang-type drying, consider these factors:

1. Initial Moisture Content

The starting moisture level of food products directly affects drying time and energy use. Products with lower moisture content will dry faster. For instance, fresh herbs contain around 80% moisture, while dried herbs have about 5%. Understanding the initial moisture content helps in planning the drying duration effectively.

2. Particle Size and Shape

Uniform particle sizes enhance drying efficiency. Smaller pieces allow for quicker moisture evaporation. When processing fruits or vegetables, cutting them into uniform sizes ensures that they dry evenly and reduces the risk of spoilage.

3. Airflow Management

Proper airflow ensures even drying across all products. Strategic placement of fans and ducts eliminates dead zones where moisture can accumulate. Using adjustable vents can help direct airflow where it's needed most, further enhancing efficiency.

4. Insulation Quality

High-quality insulation minimizes heat loss, improving energy efficiency. Insulated chambers maintain consistent temperatures and reduce energy consumption, leading to lower operational costs.

5. Automation and Control Systems

Modern machines come equipped with automated systems that monitor moisture levels and adjust parameters in real-time, ensuring optimal performance. These systems can also provide data analytics for continuous improvement.

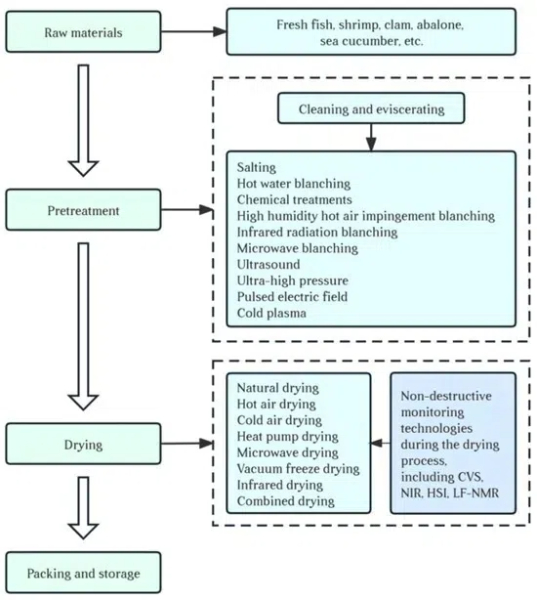

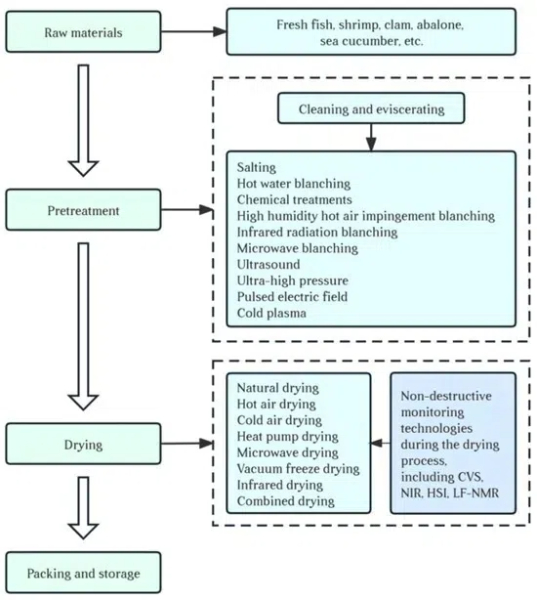

Steps in the Hang-Type Drying Process

1. Loading: Food items are hung evenly within the chamber to ensure proper airflow around each piece.

2. Heating: The heat pump system heats the air to the desired temperature based on the product being dried.

3. Circulation: Heated air circulates uniformly throughout the chamber, promoting even moisture removal.

4. Moisture Removal: Evaporated moisture is continuously extracted from the chamber using exhaust fans or condensation systems.

5. Cooling (Optional): Some models offer a cooling function to enhance product texture before unloading.

6. Unloading: Dried products are removed and prepared for packaging or further processing.

Common Challenges in Hang-Type Drying

While hang-type drying offers numerous advantages, several challenges may arise:

Uneven Drying

One common issue is uneven drying, which can occur due to improper loading or airflow issues. To mitigate this, ensure that items are spaced adequately apart and not overcrowded in the chamber.

Over-Drying or Under-Drying

Over-drying can lead to loss of flavor and nutritional value, while under-drying may result in spoilage or microbial growth. Regularly calibrating temperature settings based on product requirements is crucial for achieving desired results.

Maintenance Requirements

Regular maintenance of hang-type dryers is essential for optimal performance. This includes cleaning filters, checking seals for air leaks, and ensuring that fans are functioning correctly.

Best Practices for Successful Hang-Type Drying

To achieve the best results with your hang-type dryer, follow these best practices:

Regular Calibration

Ensure that your machine's temperature and humidity sensors are calibrated regularly to maintain accuracy.

Pre-Drying Preparation

Prepare food items properly before loading them into the dryer—this includes washing, cutting into uniform sizes, and blanching when necessary.

Monitoring During Operation

Keep an eye on the drying process by using digital controls that allow you to monitor temperature and humidity levels continuously.

Documentation and Feedback Loop

Maintain records of each batch processed—include details like initial moisture content, drying time, temperature settings, and final product quality—to identify trends and areas for improvement over time.

Conclusion

Optimizing your hang-type drying process involves understanding the machine's mechanics and controlling various factors such as airflow, temperature, humidity, and initial moisture content. By implementing these strategies and best practices, food processors can achieve higher efficiency, reduce energy costs, and maintain product quality.

FAQ

1. What types of food products can be dried using hang-type machines?

Hang-type machines are suitable for a variety of products including noodles, sausages, fish, fruits, vegetables, herbs, and more—essentially any food item that benefits from suspension during drying.

2. How does heat pump technology improve energy efficiency?

Heat pump technology recycles heat from exhaust air to preheat incoming air significantly reducing overall energy consumption by up to 75%, making it a cost-effective solution for large-scale operations.

3. What is the ideal temperature range for drying food?

The optimal temperature range for most food products is between 18-80℃ (64-176℉), allowing for precise control over the drying process based on specific product requirements.

4. Can automation enhance the drying process?

Yes! Modern hang-type dryers equipped with automation can continuously monitor conditions such as temperature and humidity levels while adjusting parameters in real-time for optimal results.

5. How does particle size affect drying efficiency?

Smaller and more uniform particle sizes allow for quicker evaporation of moisture leading to faster and more efficient drying processes; thus ensuring a consistent final product quality.

Citations:

[1] https://www.dryeratech.com/maximize-efficiency-with-hang-type-drying-machines.html

[2] https://patents.google.com/patent/CN110207480A/zh

[3] https://www.dryeratech.com/the-science-behind-hang-type-drying-machines.html

[4] https://patents.google.com/patent/WO2017197612A1/zh

[5] https://pmc.ncbi.nlm.nih.gov/articles/PMC7911452/

[6] https://patents.google.com/patent/CN1405396A/zh

[7]https://www.researchgate.net/publication/362985256_Drying_Process_Optimization_and_Modelling_the_Drying_Kinetics_and_Quality_Attributes_of_Dried_Chili_Pepper_Capsicum_frutescens_L

[8] https://patents.google.com/patent/WO2016165668A1/zh