Content Menu

● Introduction to Room Type Drying Machines

● Key Components and Innovations

● Benefits of Room Type Drying Machines

● Applications and Future Prospects

● Comparison with Other Drying Technologies

● Case Studies and Success Stories

● Conclusion

● FAQ

>> 1. What are the key benefits of using room type drying machines?

>> 2. How do room type dryers compare to freeze-drying in terms of operational costs?

>> 3. What types of food products can be dried using room type drying machines?

>> 4. How does IoT technology enhance the functionality of room type drying machines?

>> 5. What maintenance is required for room type drying machines?

● Citations:

In recent years, the food industry has witnessed significant advancements in drying technologies, particularly in room type drying machines. These innovations have revolutionized the way food is preserved, enhancing product quality, efficiency, and sustainability. This article explores the latest developments in room type drying technology, highlighting its benefits, applications, and future prospects.

Introduction to Room Type Drying Machines

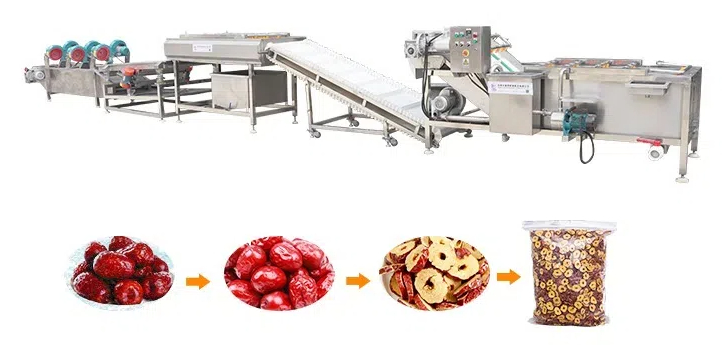

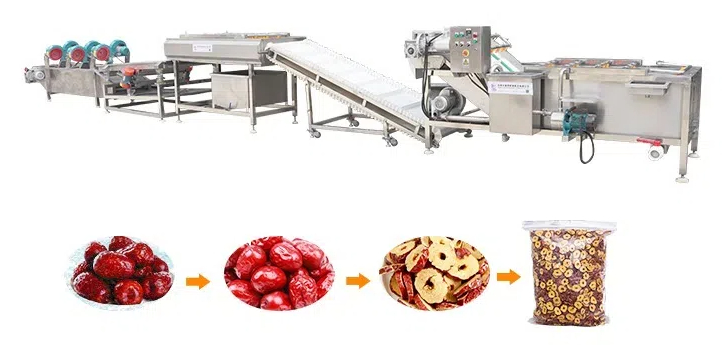

Room type drying machines are designed to provide precise control over temperature, humidity, and airflow, making them ideal for drying a wide range of food products, including fruits, vegetables, meats, and herbs. Unlike traditional drying methods, such as sun drying or tunnel dryers, room type dryers offer superior product quality and consistency. They are particularly beneficial for delicate products that require gentle drying conditions to preserve their nutritional value and texture.

Key Components and Innovations

1. Air Circulation System: A powerful fan or blower circulates heated air throughout the chamber, ensuring even distribution and maximizing drying efficiency. Adjustable airflow rates allow for precise control over the drying process, preventing overheating or under-drying. This feature is crucial for maintaining uniform drying conditions across all products.

2. Insulated Chamber: The insulated drying chamber maintains a consistent temperature and humidity level, creating an ideal environment for the drying process. The chamber's design is optimized for efficient heat retention and easy access for loading and unloading materials. This insulation also helps reduce energy consumption by minimizing heat loss.

3. Moisture Removal System: Efficient moisture removal is crucial for high-quality drying outcomes. These machines are equipped with advanced moisture extraction mechanisms, such as dehumidifiers or exhaust vents, to continuously remove moisture-laden air from the chamber. This ensures that the drying process is both efficient and effective.

4. Control Panel: A user-friendly control panel enables operators to monitor and adjust critical parameters like temperature, humidity, and airflow, ensuring precise control over the entire drying cycle. Modern control panels often include touchscreens and intuitive interfaces, making it easier for operators to manage the drying process.

5. Advanced Sensors and IoT Technology: Recent innovations include the use of advanced sensors and IoT technology, enabling remote monitoring and control. These technologies allow operators to manage multiple drying chambers from a single interface and automatically adjust drying parameters based on the specific product being dried. IoT integration also facilitates real-time data analysis, helping to optimize drying protocols for different products.

Benefits of Room Type Drying Machines

- Precision Moisture Control: Room type dryers use multi-zone humidity sensors and real-time moisture mapping to maintain optimal drying conditions, ensuring that products like mangoes achieve the desired final moisture content of 12-15%. This level of precision helps preserve the natural flavor and texture of the food.

- Vitamin Retention: Studies show that room type dryers outperform other methods in retaining nutrients. For example, they retain up to 89% of Vitamin C and 92% of beta-carotene, compared to solar dryers and tunnel dryers. This makes them an excellent choice for health-conscious consumers.

- Energy Efficiency: These machines offer energy-efficient systems that minimize power usage while maintaining optimal drying performance. They often utilize heat pump technology to recover latent heat, reducing energy consumption and environmental impact. This feature is particularly important for companies aiming to reduce their carbon footprint.

- Adaptive Heat Distribution: Advanced models feature step-down temperature protocols that deactivate oxidative enzymes at initial high heat and preserve beneficial enzymes in later stages, maintaining natural food colors and textures. This adaptive heat distribution ensures that the final product retains its natural appearance and nutritional value.

Applications and Future Prospects

Room type drying machines are versatile and can be used for drying a variety of food products. Their ability to maintain precise control over drying conditions makes them ideal for commercial applications, where consistency and quality are paramount. In the future, we can expect further innovations in automation, integration with renewable energy sources, and enhanced data analytics capabilities. These advancements will further enhance the efficiency and sustainability of drying operations.

For instance, integrating solar panels or wind turbines can provide a sustainable source of energy, reducing operational costs and environmental impact. Additionally, advanced data analytics can help predict optimal drying conditions based on historical data, further improving product quality and reducing waste.

Comparison with Other Drying Technologies

- Freeze-Drying: While freeze-drying better preserves cellular structure, room type drying offers 60% lower operational costs and higher throughput capacity, making it ideal for commercial-scale production. Freeze-drying is more suitable for high-value products where texture preservation is critical.

- Solar Drying: Room type dryers provide consistent and reliable drying conditions, unlike solar dryers, which are affected by weather conditions. Solar drying is often used in small-scale or rural settings where access to electricity is limited.

- Radio Frequency (RF) Heating: RF drying allows for uniform heat distribution but is primarily used for larger pieces of food. It is less energy-efficient compared to room type dryers and requires specialized equipment.

Case Studies and Success Stories

Several companies have successfully integrated room type drying machines into their operations, achieving significant improvements in product quality and efficiency. For example, a leading fruit drying company in Europe reported a 25% increase in production capacity and a 15% reduction in energy costs after switching to room type dryers. This transition also allowed them to expand their product line to include more delicate fruits that required precise drying conditions.

Conclusion

Innovations in room type drying technology have significantly enhanced the efficiency and quality of food drying processes. With their advanced sensors, IoT integration, and precise environmental control, these machines are poised to play a crucial role in the future of the food industry. As technology continues to evolve, we can expect even more sustainable and efficient drying solutions.

FAQ

1. What are the key benefits of using room type drying machines?

Room type drying machines offer precise control over temperature, humidity, and airflow, ensuring high-quality drying outcomes. They also provide energy efficiency, retain nutrients better than other drying methods, and are more reliable than traditional drying techniques.

2. How do room type dryers compare to freeze-drying in terms of operational costs?

Room type drying machines have 60% lower operational costs compared to freeze-drying, making them more economical for commercial-scale production.

3. What types of food products can be dried using room type drying machines?

Room type drying machines are versatile and can be used for drying a variety of food products, including fruits, vegetables, meats, seafood, and herbs.

4. How does IoT technology enhance the functionality of room type drying machines?

IoT technology enables remote monitoring and control, allowing operators to manage multiple drying chambers from a single interface. It also facilitates automatic adjustments of drying parameters based on the specific product being dried.

5. What maintenance is required for room type drying machines?

Regular maintenance includes cleaning the chamber and air circulation system, checking for blockages in the moisture removal system, and updating software for smart systems. Proper maintenance extends the lifespan of the machine and ensures consistent drying quality.

Citations:

[1] https://www.dryeratech.com/how-room-type-drying-machines-improve-product-quality.html

[2] https://www.heatandcontrol.com/news/new-dryerroaster-technology-food-industrys-current-needs-and-future-opportunities

[3] https://www.alamy.com/stock-photo/food-dehydrator.html

[4] https://www.youtube.com/watch?v=qtC36z0HleQ

[5] https://www.dryeratech.com/the-science-behind-room-type-drying-machines.html

[6] https://www.linkedin.com/pulse/food-drying-advancements-dehydration-preservation-approaches-sns-wv4oe

[7] https://www.youtube.com/watch?v=mtDzdYoyeR8

[8] https://www.youtube.com/watch?v=l81gCTvoUjg

[9] https://airtekdehydrator.com/blog/how-to-create-a-drying-room/

[10] https://www.wintersteiger.com/dry-protect/en-US/industry-solutions/hygienic-drying/production-plants-the-food-industry

[11] https://www.helperfoodmachine.com/food-drying-room/

[12] https://tunelgroup.com/drying-rooms-in-the-food-industry-essential-technology-for-long-term-food-storage/

[13] https://www.istockphoto.com/photos/food-dehydrator

[14] https://stock.adobe.com/search?k=dehydrator

[15] https://www.shutterstock.com/search/food-dehydrator

[16] https://www.istockphoto.com/photos/food-dryer

[17] https://www.electroluxprofessional.com/au/blog/the-future-of-drying-technology-innovations-in-commercial-tumble-dryers/

[18] https://theenterpriseworld.com/food-processing-equipment-trends-in-2024/

[19] https://www.petfoodindustry.com/production/pet-food-equipment/article/15706607/innovations-in-pet-food-drying-cooling-technologies-boost-efficiency-quality

[20] https://www.youtube.com/watch?v=2WUXtBVwqQk

[21] https://www.youtube.com/watch?v=OW3KndzbJXs

[22] https://www.youtube.com/watch?v=g432mYnHJ5Q

[23] https://www.youtube.com/watch?v=NfJYC2g3ywI