Content Menu

● Introduction

● Understanding Heat Pump Dryers

>> How Heat Pump Dryers Work

>> Advantages of Heat Pump Dryers

● Do You Need to Vent a Heat Pump Dryer?

>> Venting Explained

>> Heat Pump Dryers and Venting

>> Benefits of No Venting Requirement

● Applications of Heat Pump Dryers in Food Processing

>> Case Studies

● Factors to Consider When Choosing a Heat Pump Dryer

● Maintenance Tips for Heat Pump Dryers

>> Maintenance Procedures

● Innovations in Heat Pump Drying Technology

● Economic Considerations of Using Heat Pump Dryers

>> Cost-Benefit Analysis

● Environmental Impact of Heat Pump Dryers

● Conclusion

● FAQ

>> 1. What is a heat pump dryer?

>> 2. How does a heat pump dryer differ from traditional dryers?

>> 3. Can I install a heat pump dryer anywhere?

>> 4. What types of foods can be dried using a heat pump dryer?

>> 5. How often should I maintain my heat pump dryer?

● Citations:

Introduction

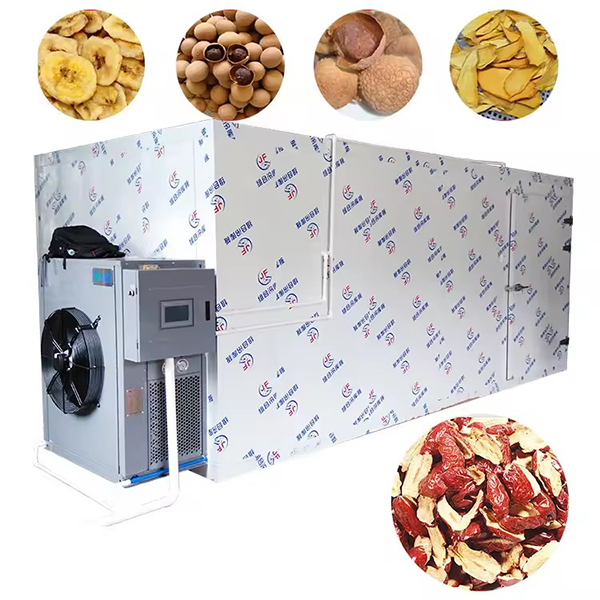

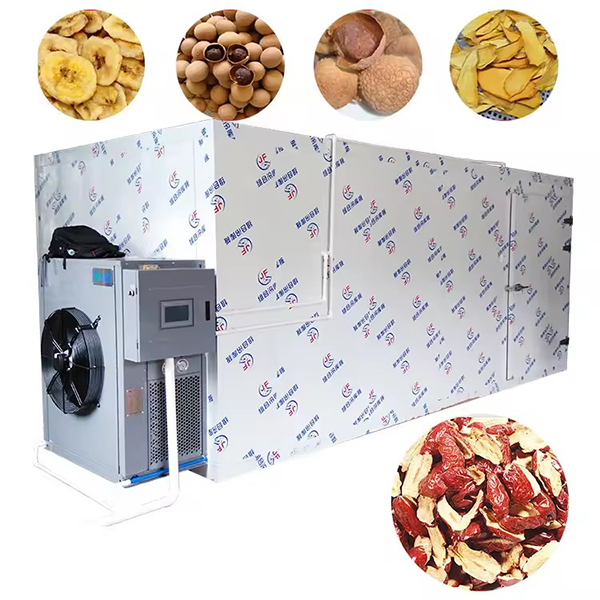

In the world of food processing, drying is an essential step that preserves the quality, flavor, and nutritional value of food products. With the increasing demand for efficient and sustainable drying solutions, heat pump dryers have emerged as a popular choice among manufacturers. This article explores the functionality of heat pump dryers, their advantages over traditional drying methods, and whether venting is required for these systems.

Understanding Heat Pump Dryers

Heat pump dryers utilize a refrigeration cycle to remove moisture from food products. Unlike conventional dryers that expel hot air outside, heat pump dryers recycle air within the system, making them more energy-efficient.

How Heat Pump Dryers Work

1. Air Intake: The dryer draws in ambient air.

2. Heat Exchange: The air passes through an evaporator where it absorbs heat from the refrigerant.

3. Moisture Removal: The warm air then enters the drying chamber, where it circulates around the food products, evaporating moisture.

4. Condensation: The moisture-laden air returns to the heat pump, where it cools down in the condenser, releasing moisture as condensate.

5. Recycling Air: The cooled air is reheated and sent back into the drying chamber.

Advantages of Heat Pump Dryers

- Energy Efficiency: Heat pump dryers consume less energy compared to traditional dryers.

- Temperature Control: They operate at lower temperatures, preserving sensitive nutrients in food.

- Environmentally Friendly: Reduced energy consumption translates to a lower carbon footprint.

Do You Need to Vent a Heat Pump Dryer?

One of the most common questions regarding heat pump dryers is whether they require venting.

Venting Explained

Venting refers to the process of expelling hot, moist air outside of a drying system. Traditional dryers typically require venting to prevent humidity buildup in the surrounding environment.

Heat Pump Dryers and Venting

Heat pump dryers do not require external venting for several reasons:

- Closed System: They operate in a closed-loop system that recycles air.

- Moisture Management: Any moisture extracted from the food is condensed and collected internally rather than expelled outside.

- Energy Efficiency: By not requiring venting, heat pump dryers maintain their energy efficiency and reduce installation costs.

Benefits of No Venting Requirement

- Flexible Installation: Without venting requirements, heat pump dryers can be installed in various locations without needing ductwork.

- Space Saving: They occupy less space and can be placed in smaller areas compared to traditional vented dryers.

Applications of Heat Pump Dryers in Food Processing

Heat pump dryers are versatile and can be used for various food products:

- Fruits and Vegetables: Retain color and nutrients while removing moisture.

- Herbs and Spices: Preserve essential oils and flavors during drying.

- Meat and Fish: Ensure safe preservation by removing moisture effectively.

Case Studies

1. Fruit Drying: A study showed that using a heat pump dryer for apple slices resulted in higher quality compared to traditional methods.

2. Vegetable Preservation: Carrots dried with heat pumps retained more vitamins than those dried using conventional methods.

Factors to Consider When Choosing a Heat Pump Dryer

When selecting a heat pump dryer for your food processing needs, consider the following factors:

- Capacity: Choose a model that meets your production volume.

- Temperature Range: Ensure it can operate at temperatures suitable for your specific food products.

- Energy Consumption: Look for energy-efficient models to reduce operational costs.

Maintenance Tips for Heat Pump Dryers

To ensure optimal performance of your heat pump dryer:

1. Regular Cleaning: Clean filters and condensate trays regularly to prevent blockages.

2. Check Seals: Inspect door seals for wear and tear to maintain efficiency.

3. Professional Servicing: Schedule periodic maintenance checks with a qualified technician.

Maintenance Procedures

Regular maintenance is crucial for ensuring longevity and efficiency:

- Inspect electrical components for wear or damage.

- Monitor refrigerant levels to ensure optimal performance.

- Clean evaporator coils to maintain airflow efficiency.

Innovations in Heat Pump Drying Technology

Recent advancements have further enhanced the capabilities of heat pump dryers:

- Infrared-Assisted Drying: Combining infrared technology with heat pump drying speeds up the process while maintaining product quality.

- Microwave-Assisted Drying: This method reduces drying time significantly by using microwave energy alongside traditional heat pump methods

These innovations allow for better control over drying conditions, leading to superior product quality.

Economic Considerations of Using Heat Pump Dryers

While the initial investment in heat pump technology may be higher than traditional methods, long-term savings can be substantial due to reduced energy consumption.

Cost-Benefit Analysis

1. Initial Costs vs. Long-Term Savings:

- Initial costs are higher due to advanced technology.

- Long-term savings on energy bills can offset initial investments within a few years.

2. Operational Efficiency:

- Reduced energy consumption leads to lower operational costs over time.

- Improved drying times increase throughput, enhancing overall productivity.

Environmental Impact of Heat Pump Dryers

Using heat pump dryers has a reduced environmental impact compared to other drying methods:

- They do not generate emissions or pollutants during operation.

Environmental Benefits

- Their energy efficiency reduces reliance on fossil fuels, contributing to lower carbon footprints.

Conclusion

Heat pump dryers are an excellent choice for food processing due to their energy efficiency, low-temperature operation, and flexibility in installation. The fact that they do not require venting makes them even more appealing for manufacturers looking to optimize their drying processes without compromising on quality or space.

In summary, if you are considering investing in a heat pump dryer for your food processing needs, rest assured that you will benefit from advanced technology designed specifically for high-quality drying without the need for external venting.

FAQ

1. What is a heat pump dryer?

A heat pump dryer is an energy-efficient appliance that uses a refrigeration cycle to remove moisture from food products without requiring external venting.

2. How does a heat pump dryer differ from traditional dryers?

Unlike traditional dryers that expel hot air outside, heat pump dryers recycle air within a closed system, making them more energy-efficient and better at preserving food quality.

3. Can I install a heat pump dryer anywhere?

Yes, since they do not require venting, heat pump dryers can be installed in various locations without needing ductwork or extensive modifications.

4. What types of foods can be dried using a heat pump dryer?

Heat pump dryers can effectively dry fruits, vegetables, herbs, spices, meat, and fish while retaining their nutritional value and flavor.

5. How often should I maintain my heat pump dryer?

Regular maintenance should include cleaning filters monthly and scheduling professional servicing at least once a year to ensure optimal performance.

Citations:

[1] https://www.guanfengmachine.com/news/what-is-a-heat-pump-dryer-in-the-food-industry-82811579.html

[2] https://vn.dryers-dehydrators.com/info/advantage-of-food-heat-pump-dryer-81163580.html

[3] http://sciencebeingjournal.com/sites/default/files/Octa%20J.%20Biosci.%20Vol.%2010%20(2)124-133_0.pdf

[4] https://pmc.ncbi.nlm.nih.gov/articles/PMC4745420/

[5] https://www.youtube.com/watch?v=wVypalh7Mrg

[6] https://www.tandfonline.com/doi/full/10.1080/15538362.2021.1911746

[7] https://www.bxdryer.com/news/industry-news/heat-pump-dryer-for-food-news.html

[8] https://pmc.ncbi.nlm.nih.gov/articles/PMC3550864/