Content Menu

● Introduction to Food Drying Machines

>> Types of Food Drying Machines

● Energy Efficiency in Food Drying Machines

>> Factors Influencing Energy Efficiency

>> Energy Efficiency Ratings

● Novel Energy-Efficient Technologies

>> Ultrasonic Drying

>> Heat Pump Technology

>> Solar Drying

● Case Studies and Examples

>> Example 1: Industrial-Scale Tray Dryers

>> Example 2: Small-Scale Home Dehydrators

>> Example 3: Large-Scale Tunnel Dryers

● Implementation and Maintenance

>> Maintenance Tips

● Future Trends in Energy Efficiency

>> Integration of Renewable Energy

>> Advanced Control Systems

● Conclusion

● FAQs

>> 1. What are the key factors influencing the energy efficiency of food drying machines?

>> 2. How do energy efficiency ratings help in choosing a food drying machine?

>> 3. What are some novel technologies improving energy efficiency in food drying?

>> 4. How does ultrasonic drying compare to traditional drying methods?

>> 5. What role do heat pumps play in enhancing energy efficiency in drying machines?

● Citations:

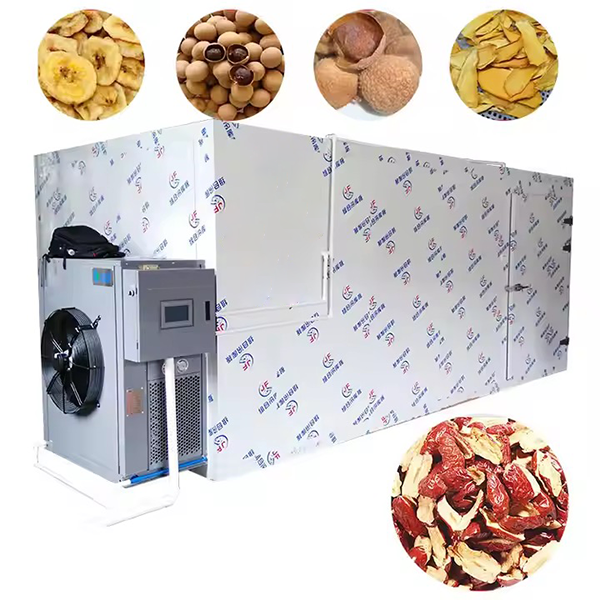

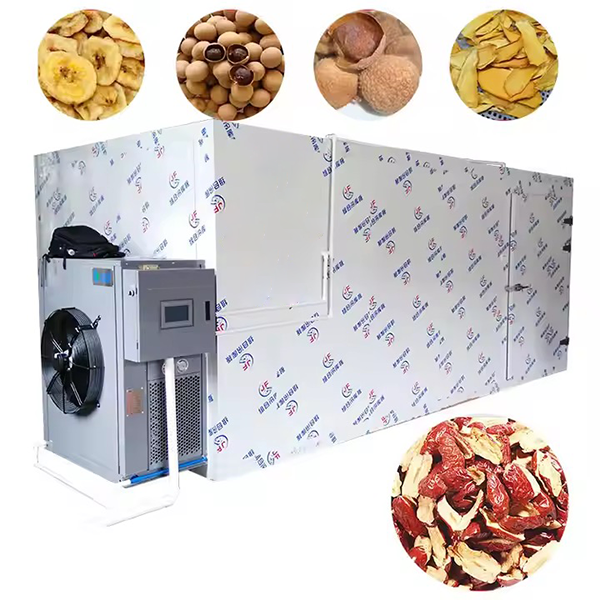

In the realm of food processing, drying machines play a crucial role in preserving food quality and extending shelf life. As a Chinese manufacturer providing OEM services for international food drying machine brands, wholesalers, and producers, understanding the energy efficiency of these machines is vital. This article delves into the world of room type drying machines, focusing on their energy efficiency ratings, technologies, and how they contribute to sustainable food processing.

Introduction to Food Drying Machines

Food drying machines, or dehydrators, are designed to remove moisture from food to prevent spoilage and enhance preservation. These machines come in various sizes and types, each with its unique features and energy consumption patterns.

Types of Food Drying Machines

1. Tray Dryers: These are the most common type, where food is placed on trays and heated air is circulated to remove moisture.

2. Tunnel Dryers: Used for large-scale operations, these dryers have a continuous conveyor belt that moves food through a heated tunnel.

3. Freeze Dryers: Utilize freezing temperatures followed by a vacuum to remove moisture, preserving nutrients and texture.

Energy Efficiency in Food Drying Machines

Energy efficiency is a critical factor when selecting a food drying machine. It not only affects operational costs but also environmental sustainability.

Factors Influencing Energy Efficiency

- Size and Capacity: Larger machines can be more efficient if they are fully utilized, as they can dry more food in a single batch, reducing the need for multiple runs.

- Temperature Settings: Higher temperatures may speed up drying but increase energy consumption. Optimal temperature settings can balance efficiency and energy use.

- Duration of Use: Planning dehydration sessions efficiently can minimize energy waste by grouping similar foods together.

Energy Efficiency Ratings

Energy efficiency ratings for food drying machines are often expressed on a scale from A++ (most efficient) to G (least efficient). Choosing a machine with a high rating can significantly reduce electricity costs and environmental impact.

Novel Energy-Efficient Technologies

Innovations in drying technologies aim to enhance energy efficiency while improving product quality.

Ultrasonic Drying

- Benefits: Reduces energy use by 20-40% compared to traditional tray dryers, decreases drying time by 25-70%, and preserves product quality without thermal damage.

- Application: Ideal for food and paper drying, offering improved texture and phenolic content.

Heat Pump Technology

- Principle: Similar to heat pump dryers used in laundry, these systems reuse heated air to remove moisture, reducing energy consumption.

- Application: While more common in laundry, integrating heat pump technology into food drying could offer significant energy savings.

Solar Drying

- Principle: Utilizes solar energy to dry food, reducing reliance on electricity.

- Application: Suitable for small-scale operations or in regions with abundant sunlight.

Case Studies and Examples

Example 1: Industrial-Scale Tray Dryers

Industrial tray dryers are widely used due to their simplicity and cost-effectiveness. However, optimizing their energy efficiency requires careful management of temperature and airflow.

Example 2: Small-Scale Home Dehydrators

Home dehydrators are popular for preserving fruits and vegetables. Models with multiple trays and adjustable temperature settings can be both efficient and versatile.

Example 3: Large-Scale Tunnel Dryers

Tunnel dryers are ideal for high-volume food processing. They can be optimized by ensuring consistent airflow and temperature control throughout the drying process.

Implementation and Maintenance

To maximize the energy efficiency of room type drying machines, regular maintenance is crucial. This includes cleaning filters, checking for air leaks, and ensuring that all components are functioning correctly.

Maintenance Tips

- Regular Cleaning: Clean the machine after each use to prevent buildup and ensure optimal airflow.

- Air Leak Checks: Regularly inspect the machine for any air leaks, which can significantly reduce efficiency.

- Component Checks: Ensure all components, such as fans and heaters, are in good working condition.

Future Trends in Energy Efficiency

As technology advances, we can expect to see more innovative solutions that enhance energy efficiency in food drying. This includes the integration of renewable energy sources and advanced control systems that optimize drying conditions.

Integration of Renewable Energy

- Solar Power: Incorporating solar panels to power drying machines can reduce reliance on fossil fuels and lower operational costs.

- Wind Power: In regions with consistent wind patterns, wind turbines can provide a sustainable source of energy for drying operations.

Advanced Control Systems

- Smart Sensors: Implementing sensors that monitor temperature, humidity, and airflow can optimize drying conditions in real-time, reducing energy waste.

- AI-Powered Optimization: Using AI algorithms to predict optimal drying parameters based on food type and environmental conditions can further enhance efficiency.

Conclusion

In conclusion, the energy efficiency of room type drying machines is crucial for sustainable food processing. By understanding the factors that influence energy consumption and adopting novel technologies, manufacturers and users can reduce operational costs and environmental impact. As the demand for efficient food drying solutions continues to grow, innovations in drying technologies will play a pivotal role in shaping the future of the industry.

FAQs

1. What are the key factors influencing the energy efficiency of food drying machines?

The key factors include the size and capacity of the machine, temperature settings, and the duration of use. Larger machines can be more efficient if fully utilized, while optimal temperature settings can balance drying speed with energy consumption.

2. How do energy efficiency ratings help in choosing a food drying machine?

Energy efficiency ratings, ranging from A++ to G, provide a clear indication of how much electricity a machine consumes. Choosing a machine with a high rating can significantly reduce operational costs and environmental impact.

3. What are some novel technologies improving energy efficiency in food drying?

Novel technologies include ultrasonic drying, which reduces energy use and preserves product quality, and heat pump technology, which reuses heated air to minimize energy consumption.

4. How does ultrasonic drying compare to traditional drying methods?

Ultrasonic drying reduces energy use by 20-40% and drying time by 25-70% compared to traditional methods. It also preserves product quality without thermal damage.

5. What role do heat pumps play in enhancing energy efficiency in drying machines?

Heat pumps work by reusing heated air to remove moisture, significantly reducing energy consumption. While more common in laundry, integrating this technology into food drying could offer substantial energy savings.

Citations:

[1] https://palmetto.com/home-electrification/best-energy-efficient-dryers

[2] https://www.aimheatpump.com/a-news-does-a-food-dehydrator-use-a-lot-of-electricity

[3] http://pdf.dfcfw.com/pdf/H2_AN202306301591940897_1.pdf

[4] https://www.energystar.gov/productfinder/product/certified-clothes-dryers/results

[5] https://www1.eere.energy.gov/iedo/downloads/2023/peer_review/Yagoobi_IEDO_Novel%20Drying%20Technologies.pdf

[6] http://static.cninfo.com.cn/finalpage/2004-06-11/14139912.PDF

[7] https://www.energystar.gov/products/clothes_dryers

[8] https://www.reddit.com/r/dehydrating/comments/15fjfvo/most_energy_efficient_dehydrator/